Stainless Steel Rod End

Our stainless steel rod ends are precision and durable for harsh environments. With more than 20 years of experience in serving OEM and industrial brand customers, we support customization of size, thread, and models. All stainless steel heim joints are CNC machined, with high strength, corrosion resistance, and smooth rotation performance. Select from greasable rod end and PTFE- lined rod end in Profab.

Professional Stainless Steel Rod End Manufacturer in China

Profab offers multiple models of ss rod ends like XM/XF, CM/CF, JMX/JFX, SATK/SITK. Each model is designed with specific load capacities and thread types to meet diverse application needs.

We provide high-quality stainless steel rod ends and professional solutions to meet the diverse needs of various industries. Whether it’s standard parts or custom-made components, we offer trusted quality, quick response, and reliable delivery for clients worldwide.

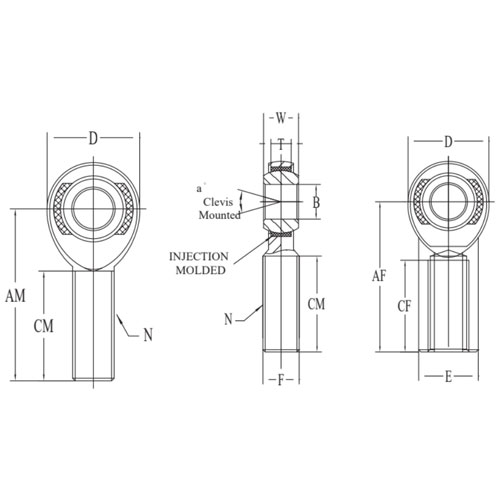

Detailed Specifications

| Material | 304 / 316 Stainless Steel (17-4ph optional) |

| Thread Type | Male & Female, Right-hand / Left-hand, Metric & Inch |

| Size: Bore | 0.19″-2.0″/5mm–50mm, Thread: 10-32 –1 1/4″ / M5–M48 / Custom Sizes |

| Surface | Polished / Passivated / Custom Finishing |

| Feature | High Load Capacity, Corrosion-resistant, Precise Rotation, Long Service Life, Maintenance-Free |

Products

Different Types of Profab Stainless Steel Rod End Series

Design: Loader Slot

Thread: Male and Female, Left Hand and Right Hand

Race: PTFE Liner

Material: 304 Stainless Housing & 440C Ball (Optional 316 / 17-4PH)

Surface: Custom Finishing Available

Design: 2-Piece Construction

Thread: Male and Female, Left and Right Hand

Race: No Liner

Material: 304 Stainless Housing & 440C Ball (Optional 316 / 17-4PH)

Surface: Custom Finishing Available

Design: 3-Piece Construction

Thread: Male and Female, Left and Right Hand

Race: PTFE Liner

Material: 304 Stainless Housing & 440C Ball (Optional 316 / 17-4PH)

Surface: Custom Finishing Available

Design: 3-Piece Construction

Thread: Male (SATK) and Female (SITK), Left & Right Thread

Race: PTFE Liner

Material: 304/316 Stainless Body & 440C Ball

Surface: Custom Finishing Available

Patch Material

Common Uses

Stainless Steel Rose Joints Applications

Profab 304/316 stainless steel rose joints are ideally suited for use in automotive suspension connections, hydraulic cylinder, marine deck rigging, and other industries. Tight tolerances are maintained even under dynamic loads. Their durable construction and self-lubricating bearings reduce the need for equipment maintenance. Profab spherical joints are designed for high loads and harsh environments. They provide long-lasting durability and reliability in a variety of applications.

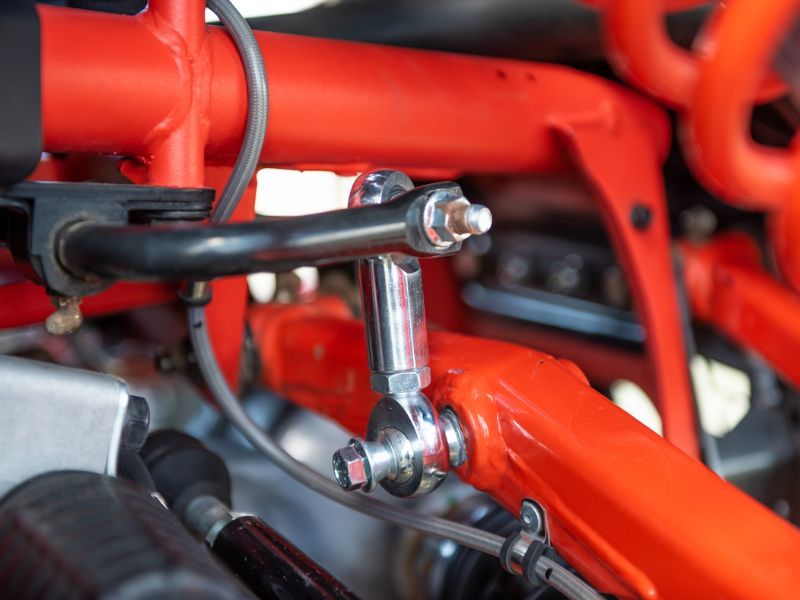

Stainless Rod Ends Built for Automotive Durability

The automotive industry demands the highest level of reliability from its components. Our XM/XF, JMX/JFX, SATK/SITK serious heim joints require no additional lubrication maintenance. They can operate for long periods of time in hot or contaminant-prone environments in engine compartments. Off-road and tuner cars are often driven in mud, rain, snow, salt water, and gravel. Profab stainless steel rod ends are made of 304/316 material. They are resistant to rust and corrosion even in harsh environments.

Why Choose Profab As Your Stainless Steel Rod Ends Supplier ?

At Profab Machine, stainless steel rod ends are more than just simple components, we are manufactured to perform perfectly in specific environments and requirements. Whether it is applications such as motorsports, automation, or marine, our rod ends are trusted for their superior strength, durability and corrosion resistance.

Precision Tolerances

Meet demanding assembly requirements. All rod joints are manufactured to exacting critical dimensions, tolerances and thread types (left/right, metric/imperial). This ensures seamless, trouble-free integration into your high-performance system.

Multiple Stainless Steel Grades

Our stainless steel rose joints are designed for long-term reliable operation in extreme conditions. Premium stainless steel grades are available depending on the environment of your application (high humidity, chemical exposure or salt water.

OEM Project Support

Our team provides full-cycle support, from prototyping to mass production to shipping, we optimize every detail to improve performance, simplify manufacturing, and support standard and custom specifications.

| Thread (mm) | Bore (mm) | Thread (Inch) | Bore (Inch) |

|---|---|---|---|

| M5*0.8 | 5 | 10-32 | 0.1900 |

| M6*1.0 | 6 | 1/4-28 | 0.1900 |

| M8*1.25 | 8 | 1/4-28 | 0.2500 |

| M10*1.5 | 10 | 5/16-24 | 0.2500 |

| M10*1.25 | 10 | 5/16-24 | 0.3125 |

| M12*1.75 | 12 | 3/8-24 | 0.3125 |

| M12*1.25 | 12 | 3/8-24 | 0.3750 |

| M12*1.5 | 12 | 7/16-20 | 0.3750 |

| M14*2.0 | 14 | 7/16-20 | 0.4375 |

| M14*1.5 | 14 | 1/20-20 | 0.4375 |

| M16*2.0 | 16 | 1/20-20 | 0.5000 |

| M16*1.5 | 16 | 5/8-18 | 0.5000 |

| M18*1.5 | 18 | 3/4-16 | 0.5000 |

| M20*1.5 | 20 | 5/8-18 | 0.6250 |

| M22*1.5 | 22 | 5/8-18 | 12mm |

| M24*2.0 | 24 | 3/4-16 | 0.6250 |

| M30*2.0 | 30 | 3/4-16 | 0.7500 |

| M36*2.0 | 36 | 7/8-14 | 0.7500 |

| M42*2.0 | 42 | 7/8-14 | 0.8750 |

| M48*2.0 | 48 | 1 1/4-12 | 1.0000 |

| Custom | Custom | 1-14 | 1.0000 |

| 1-12 | 1.0000 | ||

| 1 1/4-12 | 1.2500 | ||

| 1 1/2-12 | 1.2500 | ||

| 1 1/2-12 | 1.5000 | ||

| 1 3/4-12 | 1.5000 | ||

| 1 3/4-12 | 1.7500 | ||

| 2-12 | 2.0000 | ||

| Custom | Custom |

Competitive Prices for Brands and Wholesalers

Direct-from-Manufacturer Advantage

We are the original manufacturer—eliminate all unnecessary middlemen. That means you get the most competitive prices in the market. Enjoy maximum profit margins while ensuring consistent, high-quality stainless steel parts tailored for your business.

Engineering Support and Fast Sampling

We work closely with your technical team to understand and respond to your unique part needs. Whether it’s a CAD file, material conversion or specific tolerances, we can quickly provide samples and provide expert feedback to accelerate your product development.

Volume Discounts for Scalable Business

The more you order, the more you save. We offer tiered pricing for bulk orders, helping you stay competitive as you scale your business. Enjoy more flexible terms for long-term partnerships.

FAQ...

What stainless steel grades do you offer? Can you provide Material Test Certificate (MTC)?

We routinely provide 304, 316, 316L, and other grades. We can provide Material Test Certificate (MTC) and proof of chemical composition upon request.

How to choose the right rod ends according to the load and working condition?

Please provide the maximum static/dynamic load, mounting geometry (swing angle), shaft diameter and frequency of use. We will recommend a model or give calibration suggestions based on the load table and fatigue data.

Are there low maintenance versions with self-lubricating or polymer bushings?

Yes. For applications requiring low friction or low maintenance, we offer variants with polymer bushings or self-lubricating liners to reduce the frequency of lubrication maintenance.

Custom Your Stainless Steel Rod Ends from Profab Today!

Resource

How to Select Grease for Rose Joints

The right lubrication prevents wear, reduces friction, and ensures reliable performance in demanding applications.

Chromoly Heim Joints vs Stainless Steel Heim Joints

The differences between chromoly heim joints vs stainless heim joints include cost, durability, and performance in various conditions.

The Applications and Necessity of Stainless Steel Heim Joints in Off-Road Vehicles

For off-road and modified vehicles, corrosion, sand, dust, and salt spray are constant threats. The inherent properties of stainless steel address these challenges perfectly.