- By Profab /

- December 31, 2025

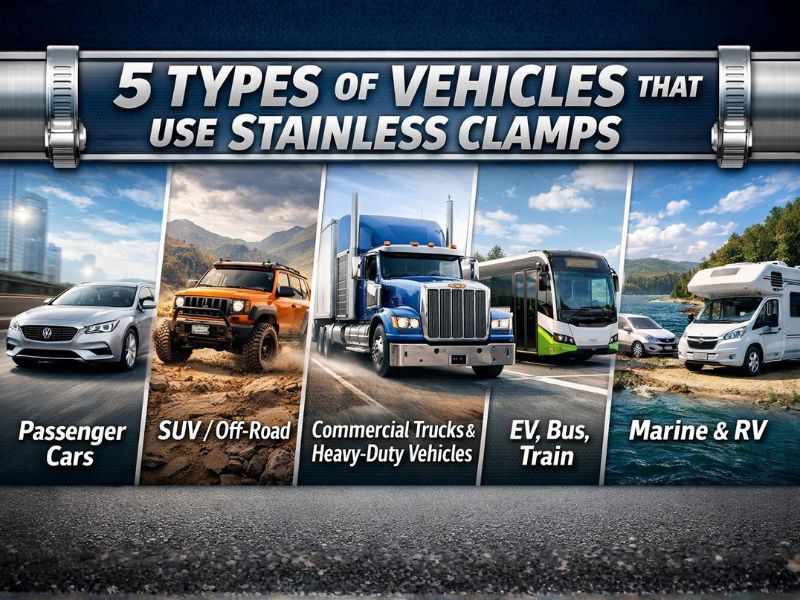

The automotive and motorcycle modification market has long been one of the most important application areas for stainless steel clamps. Different vehicle types place very different demands on clamp performance. SS T-bolt clamps, with their excellent high-temperature durability, are widely used in exhaust systems; SS V-band clamps, designed for high pressure and secure sealing, are a perfect match for turbocharger piping; and in racing and heavily modified vehicles, where components are frequently removed and reinstalled, quick-release clamps are the preferred solution.

So, which vehicles rely on stainless steel clamps the most? Next, join Profab Machine as we take a closer look at five types of vehicles that commonly use stainless clamps.

Table of Contents

1. Passenger Cars

Passenger cars face constant vibration, heat cycles, and road salt. Using high-grade stainless steel clamps ensures that connections remain leak-proof and rust-free over the life of the vehicle.

Exhaust Systems

Connecting the exhaust pipe to the muffler requires clamps that can withstand extreme temperatures without seizing. Stainless steel exhaust clamps provide a high-clamping force. They prevent exhaust leaks and resist the corrosive gases found in the tailpipe.

Cooling Systems

Maintaining a tight seal on radiator hoses and water pipes is critical to preventing engine overheating. Stainless worm-gear or constant-tension clamps provide uniform pressure on rubber hoses. It ensures they stay fixed despite the constant expansion and contraction caused by engine heat.

Fuel Line Clamps

Stainless steel fuel line clamps offer a smooth inner band. This prevents damage to sensitive fuel hoses while providing a permanent, vibration-resistant fix. It won’t corrode when exposed to fuel spills.

Air Intake Systems

To ensure peak engine performance, air inlet hoses and filters must be perfectly sealed against “unmetered” air leaks. Stainless clamps are the preferred choice for intake systems. Because they are easy to adjust and provide a clean, professional look under the hood.

Typical models

BMW、Mercedes-Benz、Audi、Tesla、Toyota、Honda、Nissan

2. Off-Road

Off-road vehicles are frequently exposed to mud, standing water, and road salt. It can cause standard steel clamps to seize or snap unexpectedly.

Heavy Machinery

The undercarriage of an off-road vehicle is a high-corrosion zone. Using stainless steel clamps to secure components tightly connected despite constant exposure to mud, salt spray, and extreme vibration. High tensile strength allows physical shocks of rock crawling and trail riding without loosening.

Hydraulic and Air Hose Supports

Stainless clamps provide the high-pressure seal that air locker lines and suspension bags need. Unlike plastic ties or plated steel, stainless clamps won’t become brittle over time. It ensures your air suspension or hydraulic lines stay firmly fixed even in the harshest outdoor environments.

3. Heavy-Duty Trucks

For heavy-duty vehicles, stainless steel clamps are the industry standard. These components are designed to handle the high-vibration and high-heat environments common in long-haul trucking.

Exhaust System and Turbocharger Connections

The connections between the exhaust manifold, turbocharger, and downpipe face the most extreme heat cycles in the vehicle. Stainless steel T-bolt and V-band clamps are essential here. Because they provide a high-torque, 360-degree seal that won’t loosen under constant thermal expansion. Using high-grade stainless steel prevents the hardware from seizing, allowing for easier maintenance of the turbo system.

Hydraulic Oil and High-Pressure Air Lines

Heavy-duty trucks rely on hydraulic systems for braking and steering, along with high-pressure air lines for air brakes and suspension. Stainless clamps offer a permanent, leak-proof fix that resists the corrosive effects of hydraulic fluid and external road chemicals. Their high tensile strength ensures that lines remain secured even during off-road construction or heavy-load hauling.

Fuel and Cooling System Lines

In a heavy-duty engine, a cooling or fuel leak can lead to catastrophic engine failure. Stainless steel worm-gear or constant-tension clamps are used to secure large-diameter radiator hoses and fuel delivery lines. These clamps provide consistent pressure that adapts to temperature changes, ensuring a secure seal that lasts for hundreds of thousands of miles.

Typical models

Freightliner、Volvo Trucks、Scania、Mercedes-Benz Actros

FAQ

4. EV, Bus, Train

These vehicles face constant high-frequency vibration. they require components that can withstand the unique challenges of electrification and mass transit.

Battery Cooling System (Electric Vehicles)

Maintaining precise battery temperatures is critical for safety and range in EVs. Stainless steel constant-tension clamps are used to secure cooling lines around the battery pack. They resist rust and provide self-adjusting pressure during thermal expansion. They ensure that the liquid cooling system remains leak-proof for the entire lifespan of the vehicle.

Air Conditioning System Fixing (Buses, Subways)

Mass transit vehicles run their HVAC systems almost continuously. Stainless clamps are used to fix air conditioning hoses and mounting brackets in buses and subway cars. Their vibration resistance prevents connections from rattling loose over thousands of miles of urban driving. Meanwhile, their corrosion resistance handles the condensation and humidity common in AC systems.

High-Pressure Line Connection

Whether it’s pneumatic lines for train brakes or high-pressure coolant loops, stainless T-bolt clamps provide the heavy-duty sealing power required. These clamps offer a 360-degree high-torque seal. They can handle significantly higher pressures than standard worm-gear clamps. They also ensure that critical safety systems in all weather conditions.

5.Marine & RV

In the demanding world of Marine and RV travel, standard hardware often fails due to constant exposure to moisture and corrosive salt. Stainless steel clamps are the critical standard for these applications, providing a “fit and forget” solution that prevents catastrophic leaks in remote locations.

Exhaust & Engine Systems

Marine and RV engines operate in high-humidity environments where standard steel clamps will pit and seize. Stainless steel T-bolt clamps are essential for securing wet exhaust hoses and turbo connections. They provide a high-torque, 360-degree seal. They won’t loosen under heavy vibration, ensuring toxic fumes stay out of the cabin or hull.

Water Pump & Plumbing

Reliable fresh water and bilge systems depend on rust-proof connections. Stainless clamps are ideal for water pump inlets and outlets because they do not “tea-stain” or degrade when submerged or tucked into damp compartments. Their smooth inner bands protect soft vinyl or rubber hoses from being cut. They maintain a watertight seal over years of seasonal use.

Fuel & Cooling Lines

A fuel leak on a boat or motorhome is a major safety hazard. Stainless steel worm-gear clamps provide a trusted vibration-resistant fix for gasoline and diesel lines. For cooling systems, ss clamps handle the constant thermal expansion and contraction of radiator hoses.

Send Inquiry Now

Related Resource

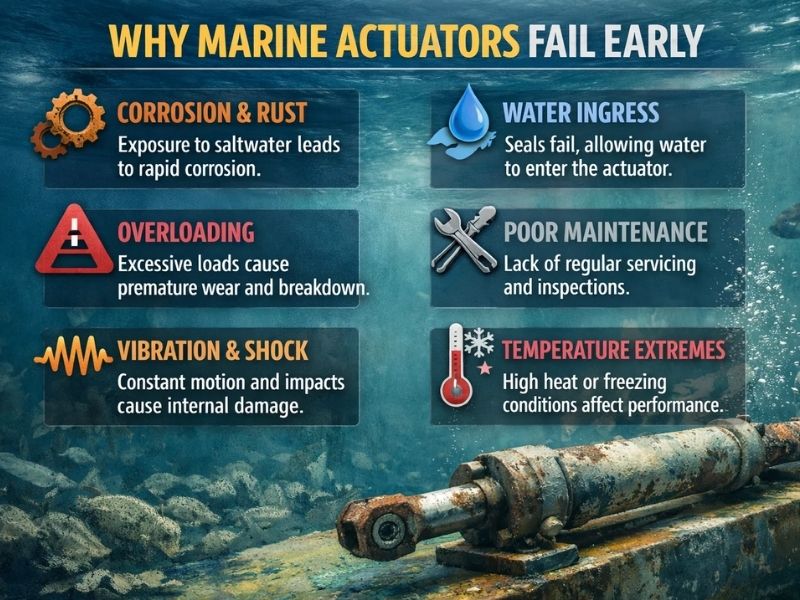

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them