Stainless Steel Powder Coating

Profab Machine

What Is Powder Coating?

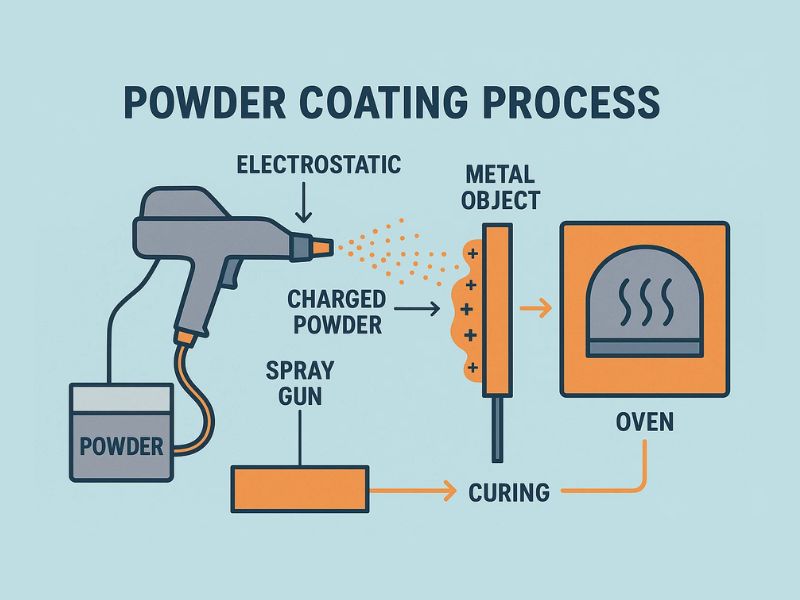

Powder coating is a dry finishing process that applies powdered polymer to a prepared metal surface and cures it to form a continuous coating.

The result is a durable, uniform finish with low VOC emissions compared with liquid paint.

Profab Machine specializes in providing industrial buyers with high-precision, high-durability stainless steel powder coating solutions. Our services are designed to overcome the challenges of traditional processes in stainless steel surface treatment, ensuring exceptional adhesion and long-lasting performance.

How does powder coating work?

Benefits of Powder Coating

Improved corrosion resistance and long-term durability.

Consistent appearance and color stability across batches.

Reduced VOC emissions and environmentally friendlier process.

Enhanced cleanability for hygienic and food-related equipment.

Wide range of textures, gloss levels, and custom RAL color matching.

Practical Uses of Powder Coating

Marine and offshore hardware requiring durable coastal finishes.

Food processing equipment needing hygienic, cleanable surfaces.

Architectural and construction hardware for consistent aesthetics.

OEM components for appliances and industrial machinery.

Chemical-processing equipment with tailored chemical resistance needs.

Why Choose PROFAB

Exceptional Adhesion Guarantee

We overcome this challenge through a rigorous multi-stage pretreatment process, including media blasting and acid etching, ensuring the powder coating forms a robust mechanical and chemical bond with the stainless steel surface.

Consistent Industrial-Grade Quality

Our services focus on overcoming industry challenges such as the Faraday cage effect, weld pinholes, and water stain residue, achieving smooth, flawless coatings.

Integrated Design-to-Production Services

Profab Machine offers one-stop in-house manufacturing and finishing services. This encompasses laser cutting, CNC machining, welding, and powder coating, ensuring seamless project management and unified quality control.

You May Also Want To Know ?

Does powder coating affect the corrosion resistance of stainless steel?

No. Powder coating adds an extra layer of protection on top of stainless steel’s inherent corrosion resistance. Especially in applications frequently exposed to highly corrosive environments such as chlorides, salts, or deicing chemicals, the additional powder coating significantly enhances the protective capabilities of stainless steel.

What is the difference between powder coating and electropolishing?

Electropolishing is a process that removes microscopic layers from a metal surface through electrochemical means to achieve a mirror finish and enhance corrosion resistance. Powder coating, on the other hand, forms a durable polymer protective layer on stainless steel surfaces to provide color, durability, and additional corrosion resistance. Both techniques can be used in combination to achieve optimal surface aesthetics and protective performance.