Stainless Steel Electropolishing

Profab Machine

What is Electropolishing?

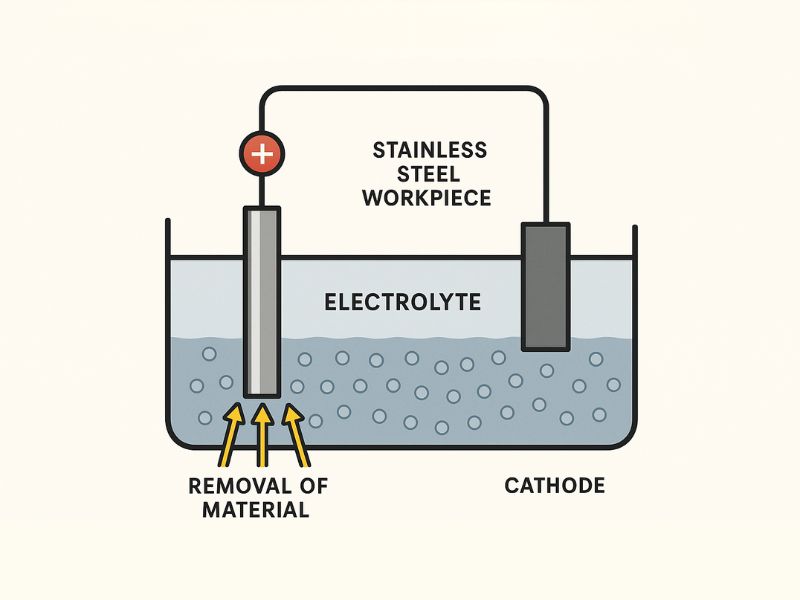

Electropolishing is an electrochemical surface treatment process. By placing the workpiece as an anode in a specific electrolyte and energizing it. Micron-sized surface metal layers are removed under controlled conditions, thereby smoothing out microscopic height differences.

This process improves the surface roughness of stainless steel fittings and enhances the surface oxidation passivation layer. The process is commonly used on 300/400 grade stainless steel. It allows for simultaneous micro deburring and removal of free iron from the surface, improving corrosion resistance and cleanliness.

How Electropolishing Works

Benefits of Electropolishing

- Reduced overhaul and maintenance costs: smooth surfaces are easy to clean and less dirt is deposited. Suitable for scenarios with high hygiene requirements.

- Improve life and reliability: Eliminate micro-cracks and micro-burrs, reduce the starting point of corrosion and fatigue cracks.

Appearance and - Supporting Performance: mirror or semi-mirror appearance can enhance the product grade, while not introducing mechanical polishing may produce surface stress or deformation.

Practical Uses of Electropolishing

- Medical Devices & Surgical Appliances

- Food & Beverage

- Processing Equipment

- Biopharmaceutical & Cleanroom Components

- Chemical & Process Equipment

- Aerospace/Automotive/Precision Components

Why Choose PROFAB

Industrial Grade Consistency

Batch-controlled process cards and online parameter logging ensure surface uniformity across high-volume production, facilitating seamless integration into customer quality systems.

Rigorous Surface Purification

Our proprietary electrolyte formulation and post-treatment passivation remove trace free iron and surface contaminants, significantly enhancing the metal's inherent corrosion resistance.

From Prototype to Production

Supports low-volume sample verification with rapid scale-up. Engineers assist in material selection and process optimization to meet specified Ra values and cosmetic requirements.

You May Also Want To Know ?

What stainless steels can Electropolishing be used on?

The common 304/316 series can be handled. 316 usually performs better in obtaining a high mirror finish.

Does electrofinishing affect subsequent welding/assembly?

Polished surfaces should be properly packaged and protected from re-contamination; if necessary, they can be partially processed and re-polished after polishing.

What is the Ra/mirror grade that the surface can achieve?

Ra 0.1-0.4 μm depending on initial processing and requirements