- By Profab /

- January 26, 2026

The food processing industry operates at a relentless pace. Speed, precision, and hygiene are fundamental requirements. Traditional conveyor belts typically restrict movement to a single linear direction, which can create bottlenecks when products need to be turned, rotated, or diverted. Ball transfer units address this limitation by enabling free, multi-directional movement across a surface. These compact yet robust components allow goods to glide smoothly in any direction with minimal force.

By integrating ball transfer units, food processing facilities can significantly reduce manual handling effort and improve overall throughput. This article explores how ball transfers enhance efficiency across modern food production environments.

Table of Contents

1. The Role of Ball Transfers in Streamlining Food Production Flow

Efficient food processing relies on smooth transitions between each production stage. Ball transfer units act as multidirectional transition points that keep products moving without interruption.

Facilitating Multi-Directional Movement

Conventional rollers are designed for forward or backward motion only. In contrast, ball transfer units allow operators to slide, rotate, and reposition containers freely in any direction. This capability is especially valuable in complex sortation areas, where food containers must be quickly oriented before entering labeling, inspection, or sealing equipment.

Reducing Manual Lifting

Crates of produce, meat, or packaged goods can easily exceed 50 pounds. Sliding these loads across ball transfer surfaces reduces the need for lifting and twisting motions. Workers can reposition items with a simple push, lowering physical strain and reducing injury risk.

Maintaining Continuous Flow Between Processing Stations

Production slowdowns often occur at transition points where one conveyor ends and another begins. Products may stall or require manual intervention. Ball transfer units bridge these transition zones, allowing items to move smoothly between systems and helping maintain a consistent downstream process rhythm.

Optimizing Packaging and Palletizing Areas

Packaging operations frequently require direction changes and lane selection. Ball transfer tables enable cartons to be diverted from a main line toward weighing stations or palletizing zones without stopping the flow. This flexibility supports multiple product streams within the same packaging footprint.

Minimizing Friction to Protect Product Packaging

Delicate food packaging can be damaged when dragged across abrasive surfaces. The smooth, spherical contact point of a stainless steel ball transfer unit reduces surface friction, helping prevent scuffs, tears, and punctures while preserving the appearance and integrity of the final product.

Improving Turnaround Times at Inspection Points

Quality control stations often require operators to temporarily remove products from the main line. Tables equipped with light-duty ball transfer units allow inspectors to rotate products freely for full visual inspection, then return them to the process quickly without disrupting overall flow.

Enhancing Layout Flexibility

Modern food facilities must adapt quickly to new recipes, package sizes, and production volumes. Modular tables fitted with ball transfer units can be repositioned easily, providing a practical solution for facilities that require frequent layout changes or scalable production areas.

Tips

Efficiency gains are most noticeable at T-junctions and L-turns, where traditional conveyor systems commonly experience flow interruptions.

Features of Stainless Steel Ball Transfers for Food Safety

Food safety is the highest priority in any processing environment. Equipment must withstand aggressive cleaning procedures while minimizing contamination risks.

Corrosion Resistance in Washdown Environments

Food processing plants rely on high-pressure water and chemical cleaners for sanitation. Standard steel components corrode rapidly under these conditions. Stainless steel ball transfer units resist corrosion and maintain smooth operation despite repeated washdowns.

Hygienic Design for Contamination Control

Food residues such as flour, sugar, or liquids can accumulate inside mechanical components. Hygienic ball transfer designs focus on smooth surfaces, minimal crevices, and effective washdown access to prevent residue buildup and bacterial growth.

Lubrication Strategies for Food-Grade Compliance

Conventional lubricants can pose contamination risks. Many food-grade ball transfer units use sealed-for-life constructions or food-approved lubricants. These lubricants also need to meet FDA and USDA compliance requirements.

Tips

Ensure the top of each ball sits slightly above the surrounding surface to minimize drag and ensure smooth movement.

Light-Duty vs. Heavy-Duty Ball Transfer Units

Selecting the appropriate load rating is critical for performance and longevity.

When Choose Light-Duty Ball Transfer Units

Light-duty units are ideal for bakery trays, small cartons, and plastic containers. They offer smooth motion at a lower cost, provided the load limits specified by the manufacturer are respected.

When Choose Heavy-Duty Ball Transfer Units

Heavy-duty ball transfer units are designed for demanding applications such as meat processing or bulk ingredient handling. These units use reinforced housings and larger balls to support higher loads without deformation or seizure.

Balancing Cost and Service Life

While light-duty units offer lower upfront costs, overloading them leads to premature wear. Investing in properly rated ball transfer units reduces maintenance frequency and prevents unexpected downtime.

Maintenance Practices for Reliable Performance

Even high-quality components require regular inspection in food environments.

Routine Cleaning Procedures

Fine powders and food residues can impair performance if allowed to accumulate. Regular washdowns or compressed-air cleaning help maintain smooth ball rotation and consistent performance.

Detecting Early Signs of Wear

Flat spots on balls, increased resistance, or abnormal noise during rotation indicate wear. Replacing worn units promptly prevents increased friction and workflow disruptions.

Advantages of Tool-Free Replacement Designs

Some systems use pop-in or quick-change ball transfer units that allow replacement without tools. This feature minimizes downtime and simplifies maintenance during production hours.

Tips

Consistent maintenance can significantly extend service life, especially in dusty or abrasive environments.

Ball transfers revolutionize food plants by enabling 360-degree movement. They speed up sortation and boost efficiency. Stainless steel BTUs ensure high hygiene and corrosion resistance.

Profab Machine supports a full range of ball transfer types, including flange mount, all stainless steel, low-profile, and sealed-for-food applications, etc. Our goals are to help streamline material handling, reduce downtime, and optimize throughput. Contact Profab Machine today to discuss your custom ball transfer solution.

FAQ

Can ball transfer bearings be used in cold storage or freezer environments?

Yes, many ball transfer bearings are designed to operate without grease or with specialized food-grade lubricants that do not freeze.

What is the benefit of using a flange-mount ball transfer?

Flange mount units offer bolted installation and stable load support, while other types prioritize compactness or recessed mounting.

Send Inquiry Now

Related Resource

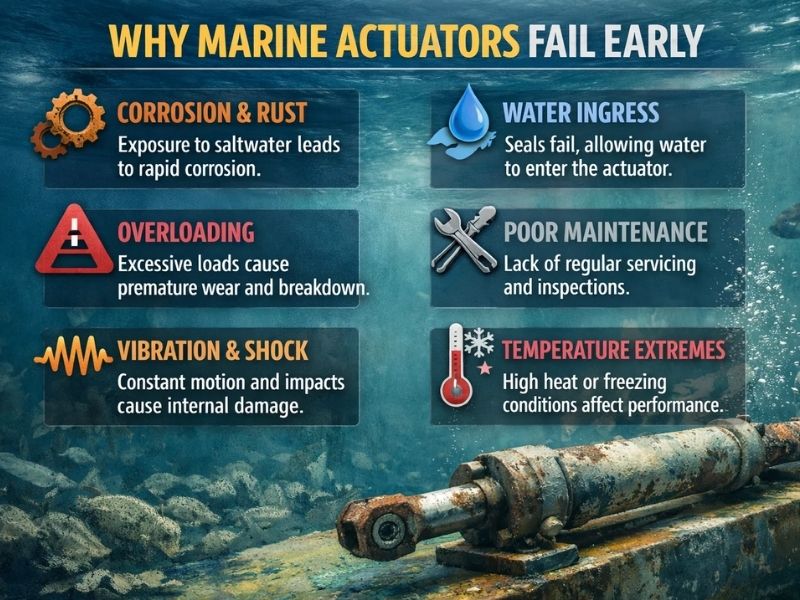

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them

The 3 Most Corrosion-Prone Parts of Hydraulic Cylinder