- By Profab /

- November 18, 2025

The world of mechanical power transmission relies fundamentally on gears. They transfer torque, change speed, and reverse direction. This article will compare spur gears and helical gears in the following five main areas:

- Structure

- Load Capacity

- Efficiency

- Noise and Smoothness

- Production Complexity

- Application Suitability

Table of Contents

Structure

Spur gears have a very simple design. Their teeth are straight and line up with the gear’s center. The teeth touch each other directly when the gears turn. This helps move power between two shafts that are side by side. Spur gears are easy to use and fix. They are great for machines that need steady movement. Stainless steel gears are strong if you need tough gears. Acetal is good if you want less rubbing and less fixing.

Helical gears have teeth cut at an angle, usually about 25 degrees. This angle lets the teeth slide into contact slowly and smoothly. Multiple teeth touch at the same time, which spreads the load and makes the gear stronger. The smooth contact between teeth means less noise and vibration. Helical gears push sideways on the shaft, so you need extra support to keep everything in place. These gears work well at high speeds and handle heavy loads with less energy loss.

Load Capacity

Spur gears generate only a radial load, simplifying the bearing requirements. Spur gears have straight teeth, so only one tooth carries the load at any moment. Spur gears work well for moderate loads. They are best for simple jobs that do not need high strength.

Helical gears, due to the angled contact, generate an undesirable axial thrust force in addition to the radial load. This necessitates the use of more complex and expensive thrust bearings. Helical gears have angled teeth that touch more than one tooth at a time. This spreads the load across several teeth. Helical gears can handle 20-30% more torque than spur gears. The angled teeth help share the force, making these gears stronger. The larger contact area in helical gears lets them carry heavier loads. You see these gears in machines that need to move big weights or work under tough conditions.

Efficiency

Efficiency tells you how much power a gear can transfer without losing energy. Spur gears can reach up to 99% efficiency. Their simple design keeps friction low. If you want the highest efficiency, spur gears are a good choice.

Helical gears usually have 94% to 98% efficiency. The sliding action and axial thrust cause a small drop in efficiency. Helical gears work better in high-speed and high-load jobs. Their design helps them run smoothly even when the machine works hard.

Noise and Smoothness

Noise and smoothness matter when you want a quiet machine. Tooth design changes how gears sound and feel when they run. Spur gears make more noise because their teeth hit each other quickly and directly. Spur gears create sudden impacts and strong vibrations. At high speeds, they get even louder.

Helical gears have angled teeth that slide into contact slowly. Helical gears reduce noise by letting teeth engage gently. You get less vibration and a smoother ride.

Production Complexity

Making helical gears is harder than making spur gears. Spur gears have straight teeth, so you can use regular machines.

Helical gears have a more detailed design. The teeth must be shaped at an angle. You need special machines and tools to make these teeth. You must be careful with the angle and how the teeth line up.

Application Suitability

Spur gears are used in lots of places because they are cheap and simple. Here are some places you might see them:

- Manufacturing: Moves things along belts and lines in factories.

- Automotive: Helps transfer power in car parts like the steering.

- Printing: Controls how paper moves in printers.

- Renewable Energy: Turns parts in wind turbines to catch wind.

- Power Tools: Helps control drills, saws, and other tools.

When you look at helical gear vs spur gear, spur gears are simple and work well. They are best for jobs that do not need to be quiet or super fast.

You will find helical gears in many machines that need smooth and quiet power. Their special design makes them perfect for tough jobs and places where noise matters.

Common uses for helical gears include:

- Medical equipment: where quiet operation is important.

- Car transmissions: need to handle high loads and run efficiently.

- Conveyors and mixers in factories: where gears must move heavy items.

- Power plants and steel mills: need strong and reliable gears.

- Turbo machinery, pumps, and compressors: where high speed and smooth power transfer matter.

- Elevators and car gearboxes: which need both strength and quiet movement.

- Printing and fertilizer industries: where machines must run smoothly and quietly.

- Earth-moving equipment: which needs gears that can handle big loads.

Helical gears give you smooth operation, high durability, and great efficiency. You can trust them in any job that needs power, quiet, and strength.

Helical and spur gears each offer distinct strengths for different load and speed requirements. Helical gears provide smoother, quieter motion, while spur gears deliver high efficiency and simple reliability. Selecting the right design ensures better performance and longer equipment life. Profab Machine supports these choices with durable stainless gears. Contact us to enhance system stability and reduce maintenance demands.

FAQ

What makes helical gears quieter than spur gears?

Can you use spur gears for high-speed machines?

Spur gears work best at low or moderate speeds. At high speeds, they get noisy and wear out faster. You should pick helical gears for machines that run fast.

Do helical gears need special support?

Helical gears push sideways on the shaft. You need stronger bearings to keep everything in place.

Where do you see spur gears most often?

You find spur gears in clocks, conveyor belts, and printers. These machines do not need to be quiet or carry heavy loads.

Send Inquiry Now

Related Resource

Advantages of Maintenance-Free Rod Ends in Hydraulic Applications

Load Capacity Considerations For Clevis Rod Ends In Construction Machinery

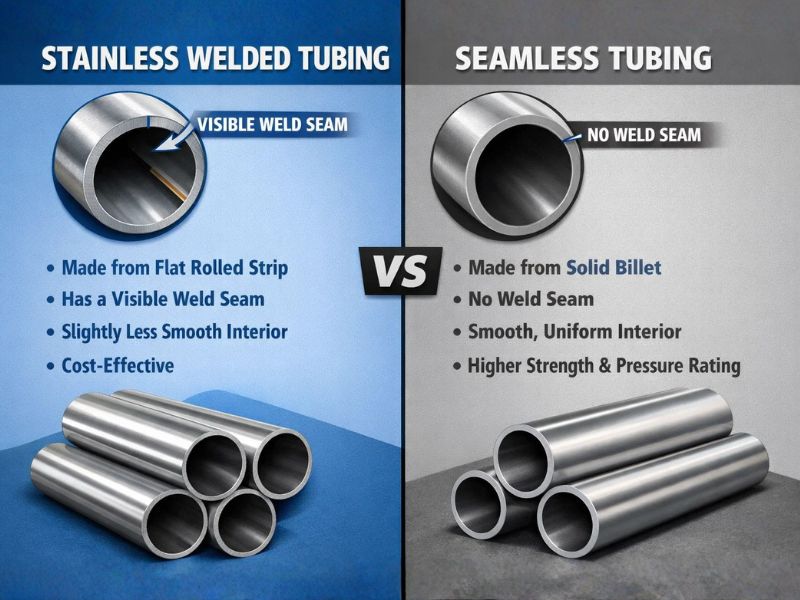

Stainless Welded Tubing vs Seamless Tubing: The Complete Comparison Guide