- By Profab /

- January 14, 2026

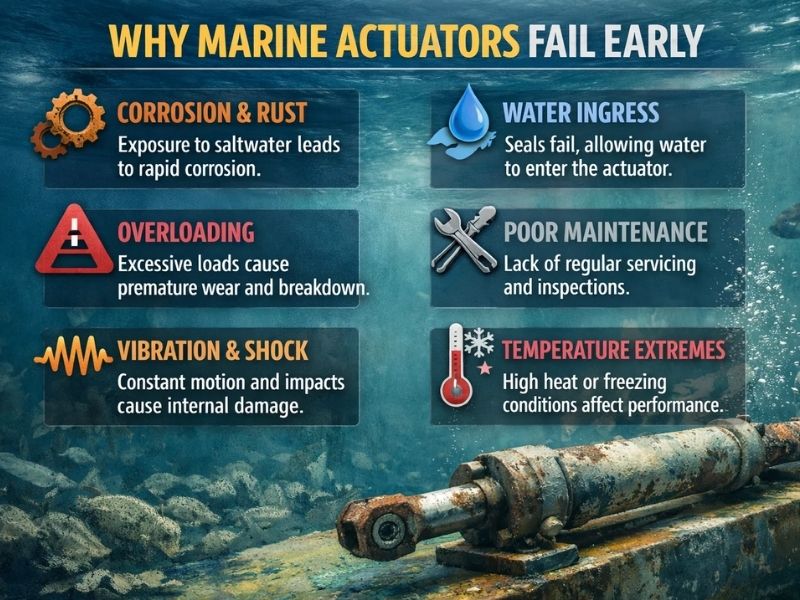

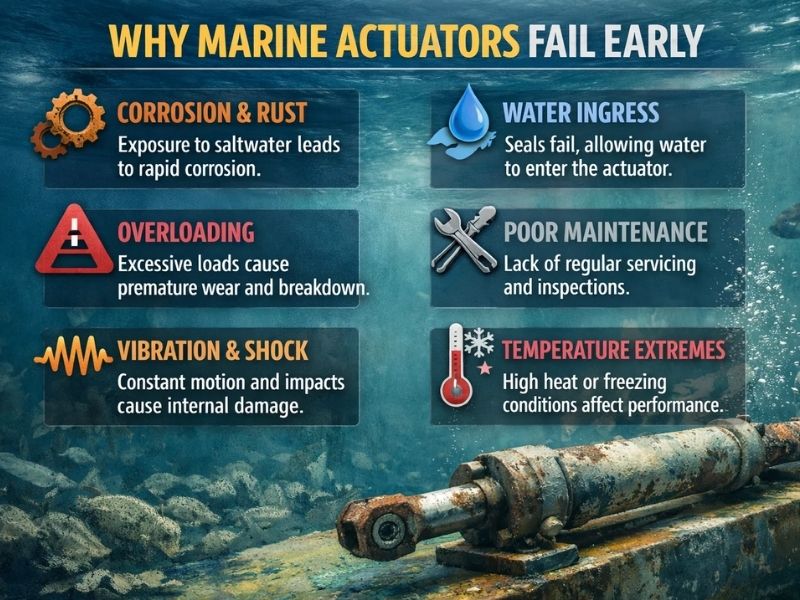

You might wonder why marine actuators fail early. Saltwater corrosion, incorrect sizing, and poor protection are leading causes. Electrical issues and lack of proper maintenance also contribute to early failures. To avoid these problems, choose the right size, ensure strong seals, and perform regular upkeep. Understanding why marine actuators fail early is key to preventing these issues and keeping your equipment running smoothly.

Table of Contents

Common Signs of Early Failure

Sluggish Movement and Inaccurate Response

Slow or inconsistent movement is often the first sign of early actuator failure. The actuator may respond with delay or fail to reach the correct position. This usually points to increased internal friction or poor alignment. In marine environments, corrosion at mechanical joints can worsen the problem. Over time, control accuracy drops, and system stability is affected.

Abnormal Noise and Excessive Vibration

Unusual noise during operation should not be ignored. Grinding or knocking sounds often indicate worn internal components. Excessive vibration is another common warning sign. It is frequently caused by loose connections or degraded linkage parts. Corroded rod ends can increase vibration and speed up fatigue in the actuator assembly. Continuous vibration reduces service life and increases the risk of structural damage.

Leaks, Electrical Faults, and High Maintenance Frequency

Hydraulic leaks are a clear sign of seal failure. Electrical actuators may show short circuits or unstable signals. These issues are common in systems exposed to saltwater and high humidity. When an actuator requires frequent maintenance, the problem is rarely isolated. Poor material quality or premature wear is often the root cause. Using corrosion resistant components such as a stainless rod end helps maintain alignment and reduces long term maintenance needs.

Why Marine Actuators Fail Early: Key Causes

Harsh Marine Environment

Saltwater is a big danger to marine actuators. When actuators are used in the ocean, saltwater can wear down materials and get past seals. Standard carbon steel parts degrade quickly under these conditions. Once corrosion spreads, alignment is affected, and wear increases across the entire actuator system.

You can lower these risks by picking actuators made from materials that fight corrosion. A stainless rod end performs well in saltwater and high-humidity environments. It resists rust, maintains joint accuracy, and reduces wear at the linkage interface. This helps extend actuator service life and lowers the risk of early failure in marine applications.

Seal Failure

Water can get inside marine actuators if seals are not strong. When water gets in, it can cause rust and leaks. It can also make electrical shorts happen. Seals can fail when they get hard or crack. This causes leaks and makes the actuator work badly.

Actuators should use seals specifically rated for marine and underwater conditions. Single lip seals are often not sufficient for long-term exposure. Multi-stage or packing seal structures provide better protection against water ingress. Surface finishes at sealing interfaces should be smooth and within tolerance to reduce abrasion. You can pick actuators with high water protection ratings. The IP68 rating is the industry standard for water protection.

Material and Manufacturing Defects

One of the most common reasons marine actuators fail early is the use of low-quality materials. It can lead to premature fatigue, corrosion, or cracking under harsh marine conditions. Poorly welded joints, imprecise machining, or substandard surface treatments are particularly vulnerable to early failure. In high-stress applications, even minor imperfections can result in leaks and structural damage in marine actuators.

Choosing high-quality, corrosion-resistant materials, such as stainless steel, and ensuring precise manufacturing processes is critical. For example, using a stainless rod end as a connection point in marine actuators. It not only reduces the risk of material fatigue and corrosion but also ensures reliable long-term performance in saltwater and high-humidity environments. Investing in well-made components can significantly extend the service life of marine actuators, reducing maintenance costs and preventing unexpected downtime.

UV and Temperature Exposure

Sunlight and temperature changes can hurt marine actuators. Too much sun can damage actuator materials. Wires can get brittle, connectors can crack, and housings can break. Extreme cold also affects how actuators work. Cold weather makes batteries weak and lubricants thick. Electronics can break from big temperature changes. Moisture from temperature changes can cause water inside the actuator.

Marine actuators should be mounted in shaded locations whenever possible, away from direct sunlight. Exposed wiring and connectors need UV rated insulation or protective sleeves. Temperature control is equally important. Actuators should not be installed near engines, exhaust systems, or other heat sources. Using covers, insulation, or enclosed mounting locations helps stabilize internal temperature. Regular visual inspections allow early detection of UV damage or temperature related wear before performance is affected.

Electrical Issues and Wiring Faults

Electrical problems are another big reason marine actuators fail early. The marine world is hard on wires and connectors. Water, shaking, and changes in temperature can all cause electrical problems. Here are some common electrical issues you might see:

- Shaking can make solder joints crack, and wires snap.

- Connectors can get loose over time, especially near engines or moving parts.

- Water can get into connectors and cause shorts or corrosion.

- Voltage spikes or drops can hurt the electronics inside the actuator.

- Bad installation, like putting actuators in wet spots or without good support, makes failure more likely.

Preventing electrical issues and wiring faults in marine actuators starts with proper component selection and installation. Use marine-grade cables and sealed connectors. Route cables away from spray zones, bilge areas, and standing water. All connectors should be properly sealed and strain-relieved to prevent water ingress and mechanical stress.

Vibration control is critical in marine applications. Secure wiring with proper clamps and supports to prevent movement and fatigue. Avoid sharp bends and unsupported cable runs, especially near engines or moving parts.

Power supply stability also affects actuator reliability. Use proper grounding and surge protection to prevent damage from voltage spikes or drops. Check that power ratings match actuator requirements.

Overload or Misuse

Excessive force increases stress on internal components and connection points. Wear accelerates quickly under these conditions. Frequent start and stop cycles also shorten actuator life. Continuous high-intensity operation raises internal temperature and increases fatigue. Mechanical joints are often the first parts to fail under repeated shock loads. Once clearance increases, vibration and misalignment follow.

High-strength connection components help reduce these risks. A stainless rose joint is designed to handle higher loads and repeated motion. It maintains joint integrity under stress and limits uneven wear. This improves reliability when actuators operate close to their performance limits.

Understanding why marine actuators fail early is the first step toward building a more resilient vessel. As we have explored, the combination of aggressive saltwater corrosion, seal degradation, and electrical vulnerabilities creates a “perfect storm” for equipment failure. However, these issues are not inevitable. By prioritizing marine-grade stainless steel components, ensuring IP68-rated protection, and adhering to a strict preventative maintenance schedule, you can significantly extend the service life of your motion control systems.

Don’t let avoidable hardware failures lead to costly downtime or safety risks at sea. Profab Machine specializes in precision-engineered stainless steel parts designed to thrive where standard components fail. Investing in high-quality materials today is the most effective way to ensure your marine actuators remain “sea-ready” for years to come.

FAQ

What is the most common reason marine actuators fail early?

Saltwater corrosion is the main cause of early failure.

What does an IP68 rating mean for marine actuators?

Send Inquiry Now

Related Resource

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them