- By Profab /

- December 18, 2025

In many mechanical systems, parts twist, tilt, and swivel under immense pressure. A spherical plain bearing functions as a highly sophisticated ball-and-socket joint. They can support massive loads. Standard ball bearings use balls to reduce friction. Spherical plain bearings rely on a sliding contact surface to accommodate angular misalignment and oscillating movements. This article will explain the bearing from construction, types, applications, and how to choose the most suitable type.

Table of Contents

Construction of A Spherical Plain Bearings

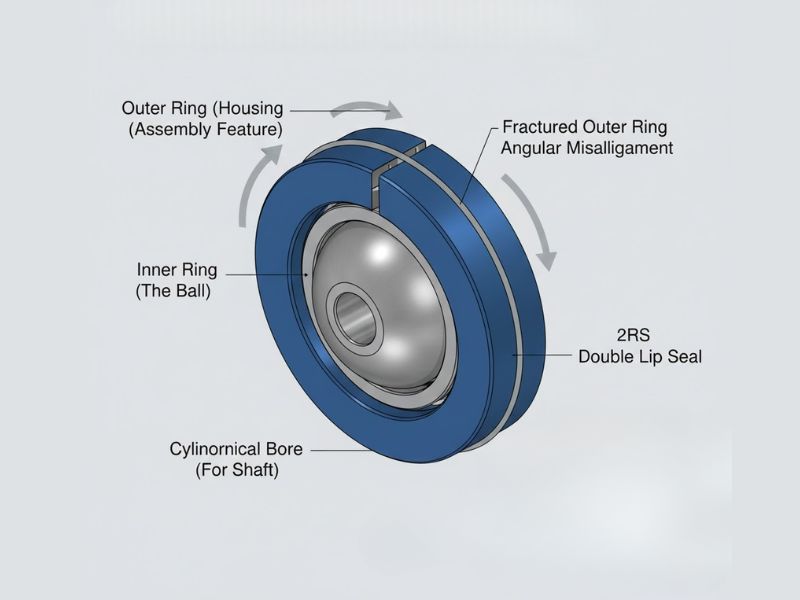

A standard radial spherical plain bearing consists of four primary elements: ball, race, sliding layer and seals. Spherical bearings have a cylindrical bore to accommodate a shaft. The outer surface is spherical and convex, precision-ground to act as the primary sliding interface. The inner surface is spherical and concave, perfectly matching the convex shape of the inner ring. The sliding layer often chooses PTFE material. Double lip seals is a common type. It can keep lubricants and protect the sliding surfaces from contaminants.

Types of Spherical Plain Bearings

This article will discuss spherical bearing by load direction. There are three primary types, each optimized for a specific direction of force.

1. Radial Spherical Plain Bearings

It’s the most common type. They are designed primarily to support forces acting perpendicularly to the shaft. The contact surface between the inner and outer rings is curved in a way that allows the bearing to compensate for significant misalignment or tilting. They are commonly used in construction machinery hinges, hydraulic cylinder rod ends, and truck suspensions.

2. Angular Contact Spherical Plain Bearings

The sliding surfaces are inclined at a specific contact angle. This geometry allows the load to be transferred from one ring to the other along that angle. They can support heavy axial loads in one direction only. To handle reversing axial loads, they must be mounted in pairs. These bearings are designed for applications where forces are applied at an angle to the axis.

3. Axial Spherical Plain Bearings

These bearings are built to handle forces acting parallel to the shaft. They can accommodate a limited radial load. Axial spherical plain bearings can support heavy downward or upward pressure.

Applications of Spherical Plain Bearings

Spherical plain bearings are designed for heavy-duty applications and low-speed rotational movements. Their ability to handle high loads and misalignment makes them essential across a wide spectrum of industries.

Heavy Machinery

This is the most common use, particularly the steel-on-steel types. Spherical plain bearings allow the hydraulic cylinder to pivot as it extends and retracts. These bearings are also used in articulated joints. They allow the front and rear of the vehicle to twist independently.

Marine

Stainless steel spherical plain bearings are the first choice for marine equipment. They can prevent seizing and rust. Stainless spherical bearings are used in rudder linkages and outboard motor pivot points. Heavy-duty crane pivots and mooring systems also need these bearings.

Aerospace

Aerospace applications often require PTFE-lined types. These bearings can reduce weight and eliminate the need for manual greasing in hard-to-reach areas. Like wing flaps, spoilers, and landing gear mechanisms.

Food

These industries use stainless steel and maintenance-free types to comply with strict hygiene standards. Like high-speed sorting, packing arms, pivot joints, and food processing lines.

Infrastructure

A quick-release clevis joint is good for fast changes. You can use one hand to open or close it. This saves time when you need to connect or remove parts a lot. It is great for repairs, service jobs, or when speed is important. The quick-release design helps you work faster and get less tired.

Automotive

Stering and suspension systems always use heim joints to provide precise, bind-free movement. The ball of heim joints isa spherical plain bearing.

How to Choose the Right Spherical Plain Bearing

Selecting the right spherical plain bearing is the first step for a successful project. There are four steps you can follow:

Step 1: Identify the Load Direction

Radial spherical plain bearings can handle a small amount of axial load. Axial spherical plain bearings are used for pure downward or upward pressure. Angular contact bearings are designed specifically for this; they are often used in pairs.

Step 2: Choose the Maintenance Type

This is the most critical decision for long-term reliability. Steel-on-steel type requires maintenance. It’s suitable for heavy static loads, shock loads, or vibration. Steel on PTFE bearings are maintenance-free. They are fit for hard-to-reach zones.

Step 3: Select Material for the Environment

Standard chrome steel is the default, but harsh environments require specialized materials. Stainless steel spherical bearings are designed for corrosive and wet environments. When the environment is contaminated with dust and sand, 2RS bearings are required. If your machine works in extreme heat. Stainless steel is a good material.

Step 4: Verify Tilt Angles

Tilt angle is the maximum angle the inner ring can swivel before hitting the edge of the outer ring. Ensure your design doesn’t exceed this limit. If it does, your bearings will wear rapidly.

Spherical plain bearings are far more than simple mechanical joints. Whether you need a high-performance racing suspension or maintain a fleet of industrial excavators, we hope this article will help you. If you need custom any spherical plain bearing, Profab Machine will be your best partner.

FAQ

How do I know when the bearing needs to be replaced?

For steel-on-steel, listen for grinding noises. For PTFE-lined bearings, once the liner is worn through to the metal backing, the friction will spike, and the joint will likely seize or develop significant “slop.”

How much "tilt" can these bearings actually handle?

Between 5° and 15° of misalignment.

Will these bearings survive in a muddy or dusty environment?

Look for the -2RS suffix. This indicates double-lip rubber seals that keep contaminants out.

Send Inquiry Now

Related Resource

5 Types of Vehicles that Use Stainless Clamps

Chromoly Heim Joints vs Stainless Steel Heim Joints