- By Profab /

- January 21, 2026

Ball Transfer Units (BTUs) are the unsung heroes of multi-directional movement. They allow heavy loads to glide, rotate, and pivot with sub-millimeter precision. Standard carbon steel components often fall victim to rapid oxidation and internal seizure. This is where stainless steel ball transfer units become an engineering necessity.

Table of Contents

What Are Stainless Steel Ball Transfer Units?

Ball transfer units are mechanical devices designed to enable 360-degree horizontal movement. Structurally, they consist of a large-diameter load ball seated on a hemispherical race formed by a set of micro support balls. They are all enclosed within a housing. This design ensures that, regardless of the direction from which the load is applied, the load ball can rotate instantly with extremely low friction.

The passive oxide layer of stainless steel prevents the internal micro support balls from seizing due to corrosion. Heat-treated stainless steel further ensures that the balls will not deform, even under long-term compression from heavy molds or large steel plates.

Function of Stainless Steel Ball Transfer Units

In heavy-duty logistics, the ability to move materials with zero-turn friction is not only a convenience but also a requirement for safety and throughput. Stainless steel ball transfer units (BTU) serve as the critical interface between linear transport and multi-axis processing.

1. Omni-Directional Movement

The primary function of a BTU is to provide instantaneous movement in any horizontal direction. In complex assembly lines, materials often need to move from a standard conveyor belt to a specialized workstation. BTUs act as the “intersection,” allowing for seamless redirection without the need for complex mechanical gates.

Stainless steel BTUs drastically reduce the manual or mechanical force required to rotate heavy pallets or containers. This enhances safety for operators and reduces the energy consumption of automated sorting systems.

2. Load Bearing and Distribution

The load capacity of a ball transfer unit does not depend solely on the main load ball at the top, but rather on its complex internal “ball bed” structure. Inside the unit, the large-diameter load ball rests on a hemispherical race composed of dozens or even hundreds of micro support balls. This design intelligently converts the concentrated point load applied to the main ball into a uniformly distributed surface load. It effectively eliminates material fatigue caused by single-point stress concentration.

3. Precision Positioning

Ball transfer units enable movement through point contact between the steel ball and the workpiece, rather than line or surface contact. This contact mode significantly reduces starting friction. It allows precise micro-adjustments with minimal external force. In assembly operations, even large and heavy workpieces can be easily “slid” into position by operators.

Material Performance Comparison for Stainless Steel BTUs

Property | 440C | 304 | 316 |

Core Strength | Extreme Hardness & Load Capacity | General Corrosion Resistance | Superior Acid/Chloride Resistance |

Load Rating | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

Rockwell Hardness (HRC) | 58 – 62 HRC | 25 – 35 HRC | 25 – 40 HRC |

Corrosion Resistance | Moderate (Best for dry settings) | Good (Freshwater/Indoor) | Excellent (Saltwater/Chemicals) |

Static Load Stability | Exceptional; resists flat-spotting | Low; prone to deformation under weight | Moderate; suitable for mid-loads |

Typical Applications | Heavy machinery, die handling, high-frequency production | Logistics, general warehousing, commercial furniture | Pharmaceuticals, food processing, offshore platforms |

Industrial Applications of Stainless Steel Ball Transfer Units

In logistics and assembly systems, ss ball transfer units significantly reduce the manual force required to move loads, improving workpiece positioning and transfer efficiency. At the same time, they help reduce operator fatigue and the risk of handling errors.

Pharmaceutical Manufacturing

In the pharmaceutical industry, equipment must withstand aggressive sanitation protocols. 316 stainless steel ball transfer units maintain full functionality even when exposed to deionized water and vaporized hydrogen peroxide. In addition, stainless steel BTUs support precise micro-positioning of heavy analytical instruments in sensitive laboratory environments.

Food and Beverage Processing

The food industry is perhaps the most demanding application for BTUs due to strict FDA/USDA regulations.

Stainless steel ball transfer units can endure high-pressure, high-temperature caustic wash-downs without rusting. This also ensures a “zero-contamination” path for food packaging and processing lines.

Metal Fabrication and Die Handling

In heavy industry, the “omni-directional” nature of the BTU is leveraged to manage massive weights with minimal manpower.

In laser and plasma cutting tables, stainless steel BTUs are used as support points for large metal sheets. The stainless material can prevent “carbon migration” or cross-contamination.

In automotive stamping, heavy dies must be slid into presses. BTUs allow for the precise “float”. They can align locating pins with sub-millimeter accuracy.

Aerospace and Defense Logistics

The aerospace industry requires components capable of handling extreme weight-to-size ratios while also maintaining non-magnetic and fire-resistant properties. In cargo loading systems, ball transfer units allow operators to easily push and rotate pallets into their locked positions. During jet engine assembly, stainless steel BTUs enable technicians to rotate engine casings smoothly without the risk of surface scratching.

Marine Engineering

On offshore oil and gas drilling platforms, space is extremely limited. Ball transfer units are integrated into deck supports and storage areas, enabling omnidirectional movement of heavy equipment crates and spare parts within confined spaces. This reduces reliance on heavy lifting equipment when fine-positioning loads.

Factors When Chhoosing Ball Transfer Units

Load Capacity

Each BTU must be rated to handle at least 1/3 of the total load to ensure safety and longevity.

Material Compatibility

Choose the ball material based on the conveyed object. Use 440C or 316 for heavy industrial loads. For glass or polished metal, we recommend Nylon or Phenolic balls.

Chemical Exposure

Assess the presence of salt, acids, or extreme temperatures. While carbon steel is economical, 316 Stainless Steel is mandatory for marine environments to prevent internal seizure from corrosion.

Orientation

Consider if the unit will be used “Ball Up” or “Ball Down”. Inverted use requires specialized spring-loaded designs. Additionally, select units with felt or rubber seals in dusty or debris-heavy environments to protect the internal ball bed.

Maintenance Tips

Regular Clear

Stainless steel is corrosion-resistant, but it is not “debris-proof.” Fragmented contaminants can enter the housing. Regularly use compressed air to blow out the unit. In food-grade or marine environments, rinse with low-pressure water and then dry with air to prevent bacteria or mineral buildup in standing water.

Lubrication

Metal and heavy-duty ball transfer units require periodic application of light grease, whereas PTFE or nylon units do not. Adding grease to plastic units can cause swelling and may scratch the main load ball.

Inspect for Skid Marks

Manually rotate each primary ball. If you feel “notching” or resistance, it indicates that the internal small support balls are contaminated or damaged. If a ball stops rotating, the load will quickly grind a flat spot onto the spherical surface.

As discussed, these ball transfer units are more than simple bearings; they manage complex load distributions and offer precision engineering solutions. Whether you require non-standard sizes, specific load ratings, or advanced sealing for extreme environments, the Profab Machine team is dedicated to providing customized engineering ball transfer solutions.

FAQ

What is the difference between "Ball Up" and "Ball Down" orientations?

Most standard BTUs are designed for “Ball Up” use, where gravity helps the support balls stay in position. If used “Ball Down” (inverted), the load capacity is typically reduced by 50% unless the unit is specifically engineered with high-tension internal springs.

What causes a ball transfer unit to "seize" and how can it be prevented?

A seizure is usually caused by ingress of debris or internal corrosion. Even small metal shards can jam the support ball bed. To prevent this, ensure your units are specified with Top Seals (felt or rubber) and feature a Debris Escape Hole at the base.

Send Inquiry Now

Related Resource

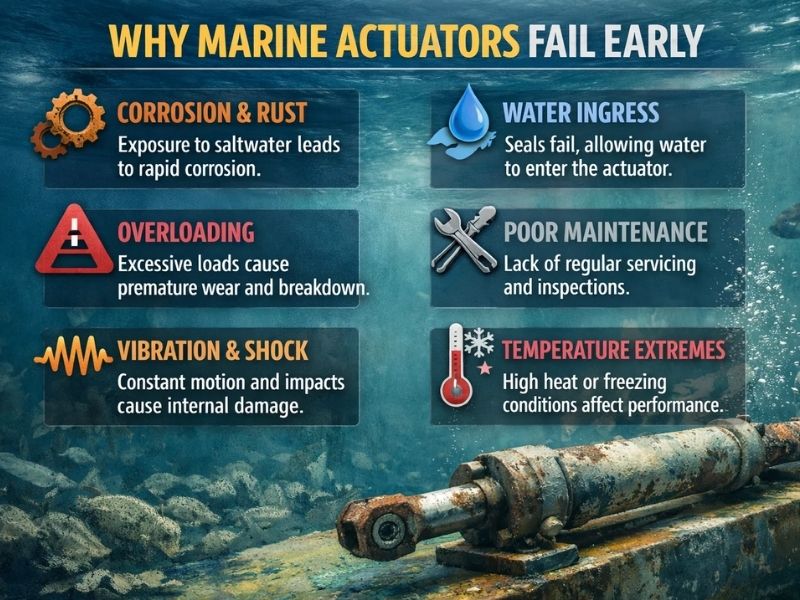

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them