- By Profab /

- September 25, 2025

Have you ever heard a strange clunking sound from your car’s front end? Or did you feel a looseness in the steering wheel when you drove over bumps? These can be concerning signs, and they often point to a critical part of your vehicle’s suspension system: the ball joint. While it might sound like a complex mechanical component, understanding what a ball joint is and what it does is crucial for any car owner. This guide will provide a straightforward explanation, helping you understand this small but mighty component, its essential functions, and how to identify problems before they become a serious safety issue.

Table of Contents

What Are Ball Joints on a Car?

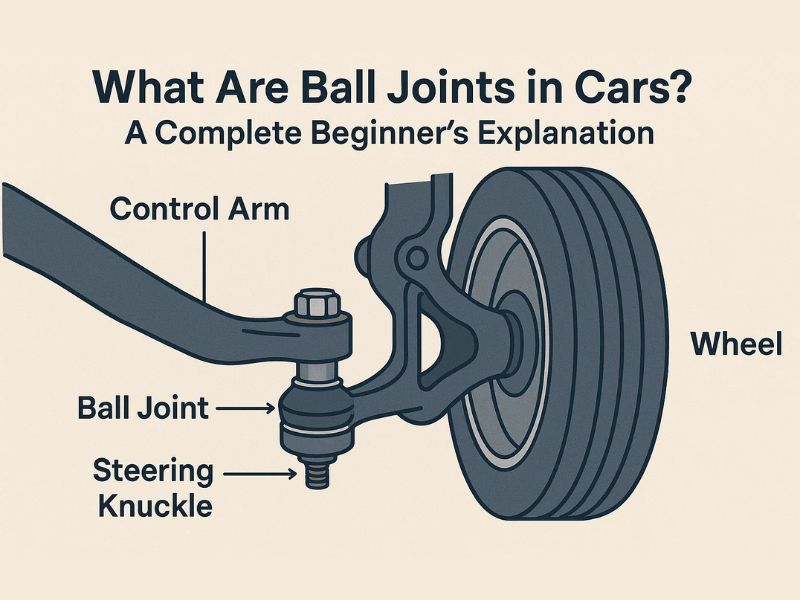

A ball joint is a pivotal ball-and-socket joint, much like the human hip or shoulder joint. Its design allows for multi-directional movement while securely connecting parts of the car’s suspension system. It is a key mechanical component that connects the control arms to the steering knuckles, serving as a critical pivot point.

This clever design consists of a spherical bearing, or ball stud, that sits inside a protective metal housing. This construction is engineered to allow the wheels to move freely in various directions. It supports the constant movement and weight of the vehicle, which is a significant structural burden. The simple ball-and-socket principle is an incredibly effective way to manage the complex forces exerted on a car’s wheels.

What Do Ball Joints Do for Your Vehicle?

The Dual Role: Steering and Suspension

The primary purpose of ball joints is to enable two of a vehicle’s most important functions. First, they allow the wheels to pivot and turn in response to steering input. This is how you are able to change the direction of your car with the steering wheel. Second, they allow the wheels to move up and down, absorbing shocks from bumps, potholes, and uneven surfaces. This is what provides a smooth and comfortable ride. The fact that a single component is responsible for both directional control and shock absorption highlights its importance. If this part fails, it can compromise two distinct and critical vehicle systems at the same time, which is why a ball joint’s health is so tied to vehicle safety.

Maintaining Wheel Alignment

Proper alignment is essential for vehicle stability, ensuring the car tracks straight and responds predictably to steering input. When ball joints wear out, they develop excessive play or looseness. This slack disrupts the precise geometry of the suspension, causing the wheels to shift out of alignment. This loss of alignment is the root cause of many of the common symptoms, such as the vehicle pulling to one side or experiencing abnormal tire wear. This shows that the part’s integrity directly affects the long-term health of other components, such as your tires.

Supporting Vehicle Weight and Movement

Ball joints are built to withstand immense forces. They are strong and durable, designed to support the continuous weight and stresses of a vehicle as it drives. Every time the car turns, brakes, or hits a bump, the ball joints are subjected to significant stress. Stainless steel ball joints offer additional advantages: corrosion resistance, less susceptibility to rust, longer life, low maintenance, and the ability to maintain consistent performance in salt spray, high temperature, or chemical environments.

How to Know If Your Ball Joints Are Worn Out?

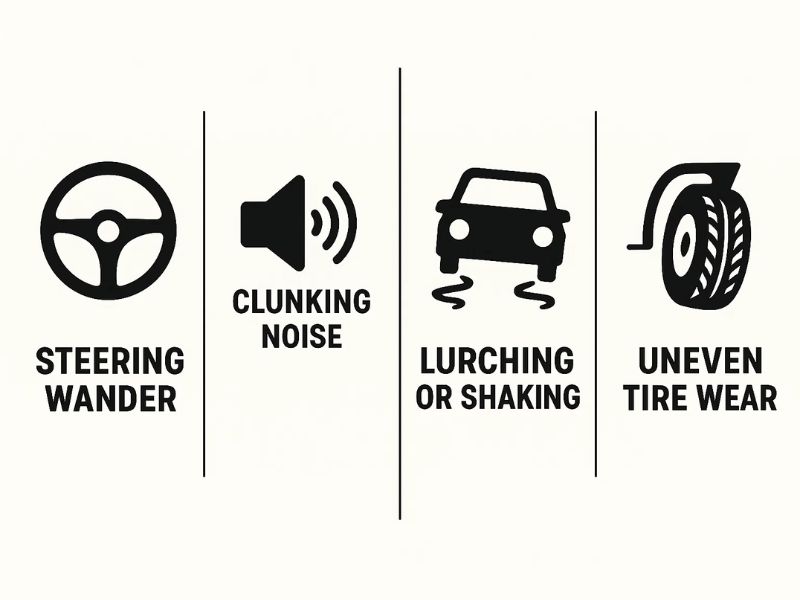

Recognizing worn ball joint symptoms helps prevent dangerous failures. Common signs include a clunking or knocking noise from the front suspension over bumps or turns, loose or wandering steering, uneven front-tire wear from misalignment, vibrations through the steering wheel or chassis, and increased effort when turning.

If you notice any of these, have the vehicle inspected promptly. If you want to know more, view how to check ball joints on trucks and UTVs.

The Consequences of Ball Joint Failure

The most serious consequence of a worn ball joint is a complete failure. A sudden and catastrophic failure can result in a dangerous loss of steering control. The suspension components may separate, or a tire could detach from the vehicle entirely. This is a severe and life-threatening event. A complete ball joint failure is a serious risk that underscores why proactive maintenance and regular inspections are not just about saving money but are paramount for safety.

When to Replace Your Ball Joints?

Ball joints are considered non-serviceable components. This means that when they show signs of wear or failure, they must be replaced as a complete unit. There is no repair or lubrication that can restore a worn joint to its original condition.

It is recommended to have your ball joints inspected during routine maintenance, which is often advised every 5,000 to 10,000 miles. A mechanic can properly check for signs of wear and recommend a replacement if necessary. When one ball joint needs to be replaced, it is common practice to replace both ball joints on the same axle at the same time. This is because they wear at a similar rate, and if one has failed, the other is likely nearing the end of its lifespan as well. Replacing both ensures consistent performance and avoids a second repair in the near future. This approach helps to manage expectations for repair costs and ensures the most effective repair.

The Importance of Professional Inspection

Driving with worn ball joints is an extremely dangerous condition that should not be ignored. The symptoms of a worn ball joint, such as vibrations or uneven tire wear, can also be caused by other issues. These include problems with a wheel bearing or a tie rod end. For this reason, a self-diagnosis is never a substitute for professional expertise.

It is vital to have a qualified mechanic inspect your vehicle as soon as you suspect a problem. A professional can properly diagnose the issue and ensure that the correct parts are chosen and installed. This is essential for both your safety and the longevity of your vehicle.

Choosing Quality Ball Joints

The importance of using high-quality replacement parts cannot be overstated. High-quality parts are crucial to ensuring the vehicle’s safety and long-term performance. Components like ball joints are engineered to withstand continuous stress. Manufacturers of these parts use high-quality materials like hardened steel and aluminum alloys. They also utilize advanced production techniques. This includes precision machining and automated quality control measures. These processes enhance the part’s resistance to corrosion and fatigue. Choosing a durable, well-made manufacturer is an investment in your safety and the reliability of your car.

Conclusion

Ball joints are small but mighty components. They enable both steering and suspension movement. Their health is critical for vehicle safety. Recognizing the common signs of wear is the first step toward a safe and timely repair. For those in the automotive and related industries, finding a reliable supplier for these crucial parts is essential. Profab Machine is a professional stainless steel parts manufacturer. They specialize in engineered, corrosion-resistant solutions. We offer high-quality stainless steel ball joints. Our commitment to strict quality assurance ensures reliable components. We provide value for automotive manufacturers and other major OEMs.

FAQ

How Many Ball Joints Does a Car Have?

Most cars have at least lower ball joints in the front suspension, and some vehicles also have upper ones. A common configuration is to have two ball joints per wheel on the front suspension: one upper and one lower.

What are the Two Main Types of Ball Joints?

Ball joints can be classified based on their position and function. The lower ball joint is located at the bottom of the front suspension. In most modern vehicles, this joint is the load-carrying one, meaning it supports the vehicle’s entire weight. The upper ball joint, located at the top of the front suspension, helps to maintain alignment and stability.

The lower ball joint is typically the load-carrying joint that bears the vehicle’s weight. The upper ball joint is a follower joint that helps guide the suspension through its range of motion.

Send Inquiry Now

Related Resource