- By Profab /

- October 21, 2025

Different types of stainless steel clamps can be used in various industries like automotive, marine, industrial, food, etc. Choosing the right clamp can prevent leaks, maintain pressure, and boost safety. Stainless steel options offer strong resistance to harsh chemicals and high pressure.

Table of Contents

What Is a Hose Clamp?

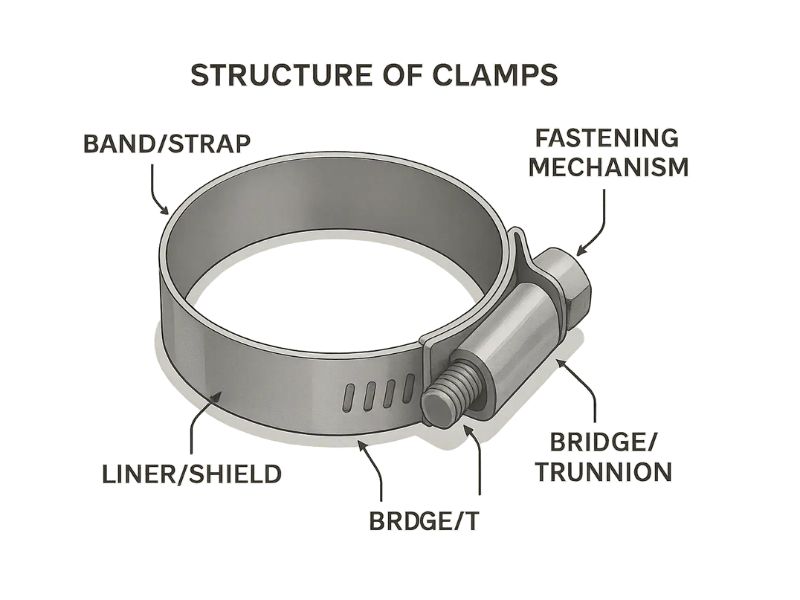

A hose clamp is a tool that holds a hose on a fitting and creates a tight seal so nothing leaks out. Industry groups set rules for hose clamps. SAE International publishes specifications: J1508 lists 32 clamp designs, such as screw, spring, and t-bolt, and J1610 explains how to test hose sealing. Hose clamps come in many shapes and sizes, and each type is made for a specific job; the most common types are worm gear, spring, ear, wire, T-bolt, band, and plastic clamps.

Why Stainless Steel Hose Clamps Are The Best Hose Clamps

The best hose clamps are made of stainless steel. Because it combines excellent corrosion resistance with high tensile strength and durability, SS clamps ensure a reliable, long-lasting, leak-proof seal in all types of fluid contact environments.

In addition, marine grade 316 stainless steel is preferred when seawater, salt spray or chlorinated environments are involved. The addition of molybdenum significantly improves resistance to salt corrosion.

Types of Hose Clamps

There are many main types of hose clamps. Each type has its own special design and job. Knowing these differences helps you pick the right one. Let’s look at each type more closely.

T-Bolt Clamps

Stainless steel is most at risk when it touches chemicals or salty things. Chloride anions, found in saltwater and some cleaners, can break the shield. These anions are in many places, like clay soil and salt rocks. Some places have a lot of chloride, up to 100,000 mg/L. Using stainless steel in pools, near the sea, or with chlorine cleaners makes rust more likely. Hot temperatures and low pH make it worse. Always rinse and dry stainless steel after it touches these things.

V-Band Clamps

V-clamps are a highly favored clamping solution among many tuning enthusiasts and in the racing world. Their operating principle involves using a V-shaped groove to securely lock two flange sections together. Compared to traditional bolted connections, the greatest advantage of V-clamps is their rapid installation and removal. For instance, in exhaust systems and turbochargers, maintenance and adjustments are extremely frequent. If secured with screws, each disassembly becomes a hassle. V-clamps, however, require only loosening a single nut for swift installation or removal.

Additionally, stainless v band clamps excel in high-temperature resistance and sealing performance. They withstand the extreme heat of engine exhaust. While more expensive than standard clamps, their value is undeniable in scenarios demanding high performance and efficiency.

Worm Gear Clamps

The worm gear clamp is the most common type of clamp in our daily lives. It is also known as a screw clamp. By rotating the screw, it tightens the band to achieve a clamping effect. The advantages of this clamp include its simple structure, low cost, and easy installation. It can be found almost everywhere, such as in washing machine drain hoses, bicycle water hoses, and some low-pressure lines in automobiles.

However, stainless steel worm gear clamps have limited locking force and are unsuitable for high-pressure or high-temperature environments. Over-tightening may also damage the hose itself.

Quick Release Clamps

Quick release clamps are specifically designed for frequent assembly and disassembly. They typically feature a quick-release mechanism, such as a buckle or spring device, allowing users to install or remove them in seconds. These clamps are particularly well-suited for racing, laboratory, and even food processing industries. For scenarios requiring regular cleaning and maintenance, quick release clamps are the ideal choice.

Compared to bolt and screw clamps, quick-release clamps save significant time and reduce reliance on tools. While they come at a higher cost, their advantages are irreplaceable in scenarios prioritizing efficiency and convenience.

Spring Clamps

Spring clamps utilize the inherent elasticity of metal to provide clamping force. Constant tension spring band clamps maintain consistent pressure. For instance, in automotive cooling system hoses, temperature fluctuations cause rubber hoses to expand and contract. Screw clamps may loosen and leak under such conditions. Spring clamps automatically adjust to maintain a constant pressure, ensuring a reliable seal.

Stainless steel spring clamps offer rapid installation but require specialized pliers for operation. Unlike screw clamps, which only need a screwdriver, spring clamps are better suited for high-volume production lines at automotive manufacturers and are less common in aftermarket repairs.

Ear Clamps

Ear clamps, also called Oetiker clamps, have one or two “ears” you pinch to tighten. You see them in cars and factories, mostly for small hoses. They make a strong seal that does not shake loose. You can put ear clamps on fast with special pliers. They fit many hose sizes and work in small spaces.

Stainless steel ear clamps are strong and do not rust, so they are good for fuel lines and cooling systems. Ear clamps are a good choice when you want a tight, hard-to-remove seal.

Application of Hose Clamps

Different industries use different types of hose clamps. Each setting has its own needs.

In high performance vehicle tuning and racing market, clamps should give a tight seal and handle engine heat. You can always see these clamps:

- Worm Drive Clamps

- T-Bolt Clamps

- Fuel Injection Hose Clamps

- Stainless Exhaust Clamps

- Spring Clamps

- Ear Clamps

- Quick Release Clamps

- Spring-Loaded Constant Tension Clamps

Marine jobs require clamps that resist rust and saltwater. You can always see these clamps:

- 316 Stainless Steel Worm Drive Clamps

- Spring-Loaded Constant Tension Clamps

- Heavy-Duty Band Clamps

- Double Wire Clamps

- Quick Release Clamps

In the Food & Beverage Industry, hose clamps are used for liquid transfer, cleaning systems, filling lines and air lines. They need to fulfill the criteria of hygiene, corrosion resistance, easy cleaning and traceability. You can always see these clamps:

- Hygienic Band Clamps

- Constant Tension Clamps

- T-Bolt Clamps

- 316 Stainless Steel Worm Drive Clamps

In the aerospace industry, hose clamps are used in fuel systems, hydraulic lines, air conditioning systems, engine accessories and cockpit equipment. They must meet the requirements of light weight, high precision, vibration resistance, high temperature resistance, reliable sealing and traceability certification. You can always see these clamps:

- Aerospace Worm Drive Clamps

- Cushion or P-Clamps

- T-Bolt Clamps

- V-Band Clamps

- Quick Release Clamp

In the garden and agricultural industry, hose clamps are commonly used in irrigation systems, sprinklers, fertilizer delivery, pump lines, greenhouse water lines and other scenarios. They emphasize corrosion resistance, sealing, ease of installation and cost control. You can always see these clamps:

- Stainless Steel Irrigation Clamps

- Worm Drive Hose Clamps

- T-Bolt Clamps

- Ear Clamps

- Spring Clamps

- Quick Release Clamps

How To Choose Hose Clamps For Your Project

When you choose a hose clamp, you need to think about a few important things. First, check the size range. Make sure the clamp fits your hose’s diameter. You want a clamp that can adjust a little bigger and smaller than your hose for a tight fit. Next, look at how to install. Some clamps need special tools, while others go on quickly by hand. Always check if the clamp meets industry standards for your job.

Here is some installation tips:

- Choose the right clamp type and size. Make sure it fits just beyond your hose’s outer diameter.

- Slide the clamp onto the hose before you attach the hose to the fitting.

- Position the clamp about 1/8″ to 1/4″ from the hose end. Make sure it sits evenly all around.

- Tighten the clamp slowly and evenly. Turn each side a little at a time. Stop when you feel resistance, then give it a small extra turn.

- Check your work. Tug the hose gently to see if it is secure. Run your system at low pressure and look for leaks.

FAQ

Can stainless steel rust if scratched?

Yes, scratches can damage the protective layer. You expose the iron underneath. Rust may form if you do not clean and dry the area quickly.

How often should you clean stainless steel to prevent rust?

You should clean stainless steel once a week. Wipe with a soft cloth and mild soap. Dry the surface after cleaning to keep it shiny.

Does saltwater cause stainless steel to tarnish faster?

Saltwater speeds up tarnish and rust. Chloride ions break the protective layer. You should rinse and dry stainless steel after contact with saltwater.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints