- By Profab /

- January 15, 2026

In marine environments, boat linkages operate under constant vibration, salt exposure, and changing loads. Steering linkages must handle multi-axis movement while maintaining accuracy. Even minor wear or binding at a joint can affect response time and steering precision, especially in rough conditions or emergency situations. From a safety standpoint, reliable linkages protect both the vessel and its crew. At sea, control is safety, and linkages are the foundation of that control.

This article focuses on three primary causes of boat linkage failure. Only by applying targeted preventive measures can the safe and reliable operation of marine systems be ensured.

Table of Contents

What is A Boat Linkage

Boat linkage refers to mechanical linkages specifically designed for marine systems. Its core function is to convert a command into physical motion. When you turn the steering wheel, the boat linkage transmits that force accurately to the steering arm, creating the required change in rudder angle.

Unlike standard industrial linkages, boat linkages operate in far more demanding conditions. Constant exposure to saltwater, humidity, and vibration makes marine-grade stainless steel linkage critical to long-term reliability.

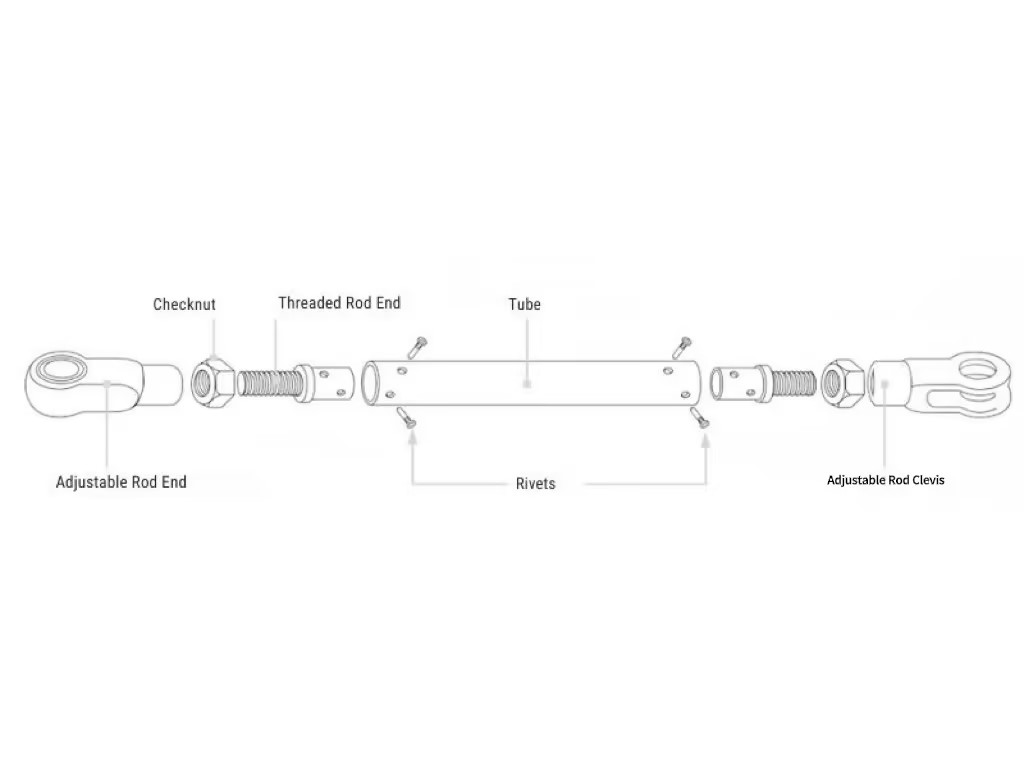

Structurally, a typical boat linkage consists of the following components:

Push-pull rods: transmit linear force

Rod ends, ball joints, spherical bearings: accommodate angular misalignment and multi-axis movement

Steering arms, clevises, pins: provide fixation and directional control

Threaded rods and lock nuts: allow installation, adjustment, and precise alignment

Failure 1: Galvanic Corrosion & Hidden Material Weakness

In the world of marine hardware, not all stainless steel is created equal. Many standard linkages use 304-grade stainless or low-grade aluminum to save costs. In a high-salinity environment, your boat essentially becomes a giant floating battery. When salt water connects different metals, an electrical current flows between them. This galvanic corrosion accelerates the breakdown of the metal at an alarming rate. Low-grade stainless steel lacks sufficient molybdenum to effectively resist chloride attack.

Standard stainless steel will rust uniformly on the outside. High-grade stainless steel often suffers from pitting corrosion. It’s a localized form of attack that creates microscopic holes deep into the metal. These pits are often hidden under washers, inside bolt holes, or beneath the ball joint’s housing. By the time a crack appears on the surface, it may lead to a sudden snap.

Proper material selection and design can significantly extend the service life of marine linkages while maintaining safe operation. Regular inspections should focus on hidden areas, and protective coatings or isolation washers can further reduce corrosion risk.

Failure2: Excessive Play and Mechanical Wear

When you turn the wheel, but the boat doesn’t respond immediately. You are likely experiencing “steering slop.” This occurs when the ball and socket inside a joint wear down, creating excessive mechanical play.

This wear is more than just an annoyance, it causes a loss of precision that can be dangerous at high speeds. 316 rod end linkages often feature self-lubricating PTFE liners. These liners eliminate metal-to-metal contact. They can also ensure that the steering remains tight and responsive even after seasons of heavy use.

Failure3: Fastener Fatigue and Improper Torque

Constant engine vibration is the “slow killer” of marine linkages. Over time, vibrations can loosen even the tightest nuts. The weakest link in many systems isn’t the rod itself, but a loosened Nyloc nut or a missing cotter pin.

A common mistake is reusing nylon-insert lock nuts. These are designed for one-time use; once the nylon is deformed by the thread, it loses its gripping power. Always use new, 316-grade fasteners and ensure safety pins are properly bent and seated. If a fastener fails, the entire linkage can detach, leaving your engine flopping uncontrollably. It is known as “hard-over” steering.

Boat linkage failures rarely happen without warning. Corrosion develops quietly, wear increases gradually, and fasteners loosen over time. What makes these failures dangerous is not their complexity, but how easily they are overlooked. In a marine steering system, every rod end, bearing, and fastener plays a direct role in maintaining control. Choosing a trusted boat linkage manufacturer and committing to regular inspection are not optional steps. By addressing these three failure modes proactively, operators can preserve steering accuracy, reduce unexpected breakdowns, and most importantly, protect safety at sea.

FAQ

Is "steering slop" normal in older boats?

While common, it is not “normal” or safe. It indicates that the tolerances in your rod ends or ball joints have exceeded their safe limit. Replacing them with precision-lined joints will usually make an old boat feel brand new again.

Why did my stainless bolt snap when it looked perfectly clean?

This is likely due to the “Invisible Threat” mentioned—pitting corrosion. The salt eats the metal from the inside out, leaving a shiny exterior but a hollowed-out core that can’t handle the torque of a turn.

Can I use automotive rod ends on a boat?

Never. Automotive parts are often made of 304 stainless or chrome-plated steel. They will show signs of failure within weeks in a saltwater environment. Only use 316 marine-grade hardware for any steering-critical application.

Send Inquiry Now

Related Resource

5 Types of Vehicles that Use Stainless Clamps

Chromoly Heim Joints vs Stainless Steel Heim Joints