The "Impossible" Hole Tolerance

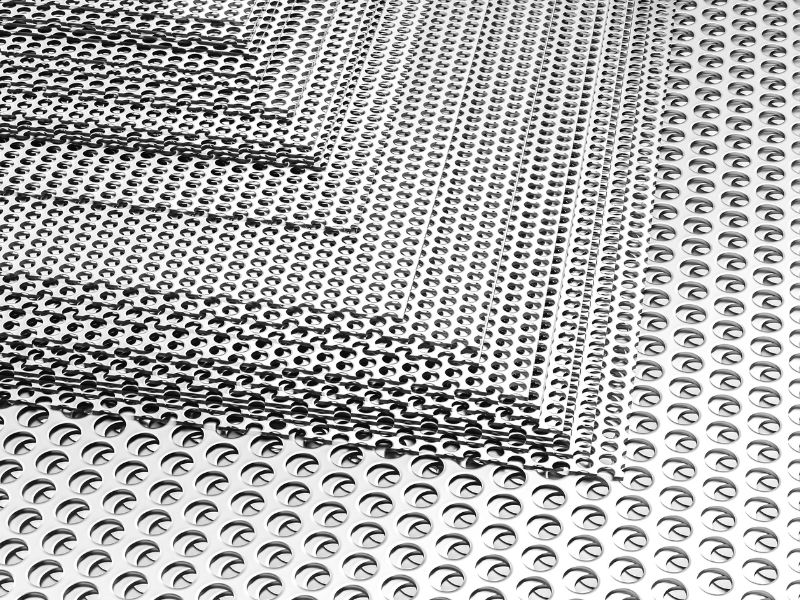

In March 2024, Profab was presented with a task that the customer described as ‘seemingly impossible’. Mr Saito of Osaka, Japan, had ordered a total of 1,200 pieces of 316L stainless steel manifold plates from us, and placed the order on 3 March.

After the initial processing of the first batch of 300 pieces was completed on 10th March, Mr. Saito urgently proposed to tighten the tolerance of the centre hole from the original ±0.05 mm to ±0.01 mm. This requirement far exceeded the conventional processing capacity, and if it was impossible to meet the standard stably, it would not only result in a large number of scraps, but also could not be completed in time for the delivery deadline of 1st April.

In the face of this ‘crisis’, we quickly launched an emergency plan:

Tool upgrading: the first time to contact with Germany’s famous carbide tool suppliers, and expedited the customisation of special tools to meet the needs of ultra-precision hole reaming;

Process reconstruction: optimise the machining process, adjust the cutting parameters, combine the precision grinding machine and high rigidity fixture to ensure that each tool can play the ultimate precision;Manpower scheduling: organising three shifts of 24-hour continuous production to ensure seamless integration of production rhythm and quality supervision;

After 10 days of day and night fighting, Profab team completed the CMM inspection of all 1,200 pieces of products on 29th March, and all the centre holes were stabilised within ±0.01 mm, and were shipped on time. After receiving the goods, Mr Saito commented highly: ‘You have done the impossible. Japanese customers rarely praise their suppliers in this way – but you deserve it.’