- By Profab /

- February 4, 2026

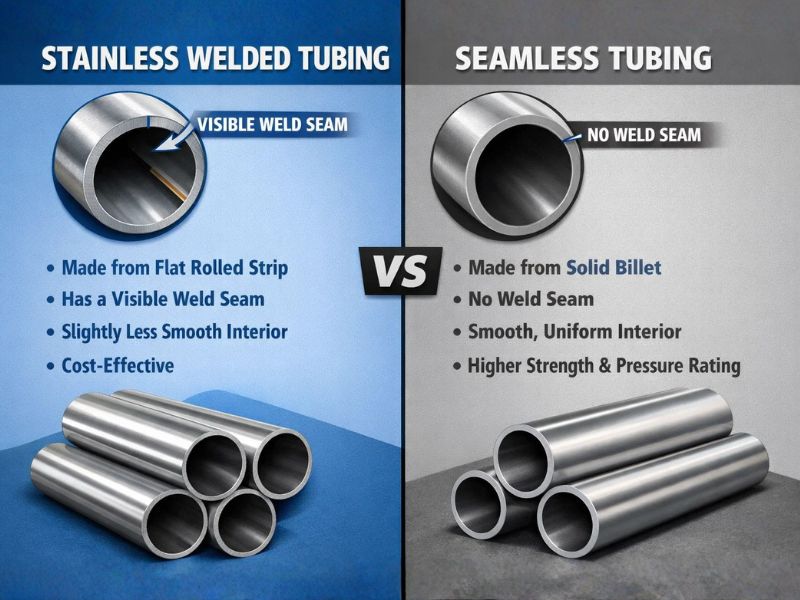

Stainless steel tubing powers industries from automotive manufacturing to petrochemical processing. Then here is the question: welded tubing or seamless? These distinct production methods create products with different strengths and limitations. This choice directly impacts system safety, operational performance, and project budgets.

This guide examines manufacturing processes, performance characteristics, and cost considerations. We’ll explore real-world applications where each type excels. You’ll learn when seamless tubing justifies its premium price. You’ll discover where welded tubing delivers optimal value.

Table of Contents

Understanding Manufacturing Methods

Seamless Tube Production Methods

Seamless tube production begins with solid steel billets. Manufacturers heat these billets to extremely high temperatures. The rotary piercing process creates the initial hollow form. A piercing mandrel pushes through the heated billet center. This creates a thick-walled hollow shell. The process requires precise temperature control and positioning.

Mandrel milling follows the piercing operation. This technique elongates the hollow shell. Multiple rollers reduce wall thickness while increasing length. Hot extrusion provides an alternative manufacturing route. Manufacturers force heated billets through shaped dies. This creates seamless profiles in various sizes. Cold drawing achieves final dimensions and surface finish. Workers pull the tubing through precision dies. This process improves dimensional accuracy significantly.

Pilgering offers another finishing method for seamless tubing. It uses reciprocating dies to reduce diameter. The technique produces exceptionally tight tolerances. Production complexity makes seamless tubing time-intensive.

Welded Tubing Manufacturing Methods

Welded tubing manufacturing starts with flat steel strips. These coils unwind and enter forming rolls. The strip gradually curves into a circular shape. Edge preparation occurs before the welding operation.

High-frequency induction welding is most common. Electrical current heats the strip edges. Pressure forces the molten edges together instantly. Electric resistance welding (ERW) provides another option. Electric current passes through the material itself. Heat generated at the interface fuses the edges.

Laser welding offers the most precise method. Focused laser beams melt the edges cleanly. This produces narrow, consistent weld seams. Bead reduction follows the welding process. Cold rolling or forging reduces the weld protrusion. This creates a smoother interior and exterior surface. Drawing operations improve the final finish. They enhance dimensional tolerances and surface quality. The process also relieves residual stresses.

Key Differences in Production Complexity

Manufacturing efficiency varies dramatically between these methods. Welded tubing production runs continuously at high speeds. Seamless tube production requires multiple heating and forming steps.

Lead times reflect this production complexity difference. Welded tubing often ships within days or weeks. Seamless tubing may require 4-8 weeks delivery. Material thickness affects process selection significantly. Welded methods excel at thin-wall, large-diameter configurations. Seamless production handles heavy-wall tubing more effectively.

Production volumes influence availability and pricing. Welded tubing production scales easily for high volumes. Seamless manufacturing has more capacity constraints. Cost differences stem directly from production complexity. Welded tubing costs 20-40% less than equivalent seamless grades. This price gap remains consistent across most specifications.

Performance: Welded Tubing vs Seamless

1. Pressure Capacity and Strength Ratings

Is seamless pipe stronger than welded? The answer is definitively yes for pressure applications. Seamless tubing provides 20-25% higher pressure capacity. This advantage comes from uniform wall thickness throughout. There are no weak points from weld seams.

The weld seam creates stress concentration points. These areas experience higher localized stresses under pressure. Failure analysis often shows cracks initiating at weld zones. Consider a 1-inch diameter tube in 316 stainless. Seamless tubing might rate at 5,000 PSI working pressure. Equivalent welded tubing rates at approximately 4,000 PSI.

Heat-affected zones near the weld introduce additional concerns. The welding process alters the metallurgical structure. This can reduce corrosion resistance and mechanical properties.

2. Corrosion Resistance Comparison

Seamless tubing offers superior corrosion resistance. Its homogeneous grain structure resists chemical attack uniformly. There are no vulnerable seam areas. Weld seams create potential weak points for corrosion. The heat-affected zone may have different metallurgical properties. Carbide precipitation can occur during welding.

Residue and contamination trap more easily near welds. Even with bead reduction, microscopic irregularities remain. These areas accumulate corrosive substances over time. Surface finish affects corrosion resistance significantly. Seamless tubing typically achieves smoother interior surfaces. This reduces fouling and biological growth. Material consistency matters in corrosive environments. Seamless construction maintains identical properties throughout. Welded tubing shows property variations near the seam.

3. Structural Integrity and Durability

The continuous grain structure of seamless tubing distributes stress evenly. This provides exceptional reliability for critical applications. Seamless construction handles cyclic loading better. Welds can develop fatigue cracks over time. Weld integrity requires careful quality control. Even high-quality welds introduce some discontinuity. Non-destructive testing verifies weld soundness.

Temperature cycling stresses welds particularly. Thermal expansion rates may differ slightly across seams. This creates additional stress during heating and cooling. Seamless tubing ensures long-term reliability in demanding environments. Nuclear, aerospace, and high-pressure applications specify seamless. The cost premium justifies the enhanced safety.

4. Dimensional Tolerances and Consistency

Welded tubing offers advantages in dimensional control. Wall thickness consistency exceeds seamless tubing typically. The forming process produces very uniform walls. Surface quality often favors welded production. Cold-drawing operations create excellent finishes. This matters for applications requiring smooth surfaces.

Outside diameter precision reaches tighter tolerances with welding. The sizing process controls dimensions accurately. Seamless production shows more variation. Interior surface characteristics differ between methods. Seamless tubing may have slight spiral marks. Welded tubing shows longitudinal seam characteristics. Length availability strongly favors welded tubing. Seamless production has more practical length limits.

5. Size and Configuration Flexibility

Large diameter thin-wall tubing requires welded construction. The forming process handles these proportions easily. Seamless methods struggle with large, thin configurations. Heavy-wall tubing applications favor seamless production. The rotary piercing process excels at thick walls. Welded methods have practical thickness limits.

Seamless square steel tubing has significant limitations. The extrusion process works better for round profiles. Welded methods form square and rectangular shapes easily.

Diameter ranges differ substantially between methods. Welded production handles 1/4 inch to 48 inches. Seamless tubing typically maxes around 16-20 inches. Custom shapes and profiles favor welded manufacturing. Roll forming adapts to various configurations. Seamless production requires specific tooling for each shape.

6. Testing and Quality Assurance Requirements

Seamless tubing requires no weld integrity testing. The manufacturing process eliminates that failure mode. This reduces inspection time and costs. Welded pipe connections demand thorough inspection. Non-destructive testing verifies weld quality. Ultrasonic, radiographic, or eddy current methods apply.

Hydrostatic testing proves pressure integrity. ASTM A269 specifies standard test pressures. Both tubing types undergo this verification. Quality control processes vary by manufacturing method. Welded production monitors weld parameters continuously. Seamless manufacturing tracks dimensional consistency primarily.

Certification documentation differs between types. Welded tubing includes weld procedure qualifications. Seamless tubing focuses on material certifications.

7. Cost Analysis: Investment vs Value

Seamless tubing requires no weld integrity testing. The manufacturing process eliminates that failure mode. This reduces inspection time and costs. Welded pipe connections demand thorough inspection. Non-destructive testing verifies weld quality. Ultrasonic, radiographic, or eddy current methods apply.

Hydrostatic testing proves pressure integrity. ASTM A269 specifies standard test pressures. Both tubing types undergo this verification. Quality control processes vary by manufacturing method. Welded production monitors weld parameters continuously. Seamless manufacturing tracks dimensional consistency primarily.

Certification documentation differs between types. Welded tubing includes weld procedure qualifications. Seamless tubing focuses on material certifications.

Industry Applications: Where Each Type Excels

Critical High-Pressure Applications

Oil and gas operations demand seamless construction. Drilling systems operate at 10,000+ PSI regularly. Welded tubing cannot meet these pressure requirements safely. Petrochemical processing specifies seamless for critical systems. Reactor vessels and high-pressure piping need maximum reliability. The cost premium is insignificant compared to failure consequences.

Nuclear power plants use exclusively seamless tubing. Radiation exposure combined with high pressures requires perfection. Regulatory requirements mandate seamless for reactor systems. Hydraulic systems in heavy equipment choose seamless. Mobile hydraulics see extreme pressure spikes. Construction and mining equipment relies on seamless strength.

These applications share common characteristics. Pressure exceeds 3,000 PSI working conditions. Failure consequences include environmental disasters or loss of life.

High-Temperature Service Requirements

Boiler tubes must withstand extreme thermal conditions. Seamless construction prevents weld seam failures. Power generation facilities specify seamless exclusively. Heat exchangers in chemical plants use seamless tubing. Thermal cycling stresses welds excessively. Seamless integrity ensures continuous operation.

Chemical processing equipment operates at elevated temperatures. Seamless tubing maintains properties above 800°F. Welds may lose strength at these temperatures. Aerospace applications require seamless for engine components. Jet engine temperatures exceed welded tubing capabilities. Weight and reliability both favor seamless.

Temperature ranges above 600°F typically require seamless. The weld heat-affected zone weakens at high temperatures. Safety factors demand seamless construction.

Automotive and Exhaust Systems

Exhaust systems universally use welded stainless tubing. Temperatures remain moderate compared to engine internals. Cost and availability make welded ideal. Manifolds, headers, and tailpipes specify welded construction. These components see pressures well below tubing ratings. The weld seam poses no safety concerns.

Common grades include 304, 321, and 409 stainless. Grade 409 offers cost-effective ferritic stainless. Premium exhaust systems use 321 for heat resistance. High-volume production demands welded tubing economics. Automotive manufacturers save millions using welded material. Performance remains entirely adequate for the application.

Tips

Automotive exhaust applications rarely exceed 150 PSI, well within welded tubing capabilities for these temperatures.

Structural and General-Purpose Applications

Construction industries rely heavily on welded steel pipe. Handrails, barriers, and structural elements use welded. Aesthetics and cost both favor this choice. Architectural applications choose welded for appearance. The smooth, consistent surface finish looks professional. Polish and chrome plating work beautifully.

HVAC systems specify welded tubing throughout. Pressures remain low in heating and cooling systems. The cost savings are substantial. Furniture and equipment manufacturing uses welded extensively. Office furniture, gym equipment, and displays use welded. Strength requirements suit welded construction perfectly.

General plumbing applications work well with welded. Potable water systems operate at moderate pressures. Welded stainless provides corrosion resistance economically.

Specialized Industries: Medical, Marine, and Food Processing

Medical device manufacturing often specifies seamless tubing. Implantable devices require absolute reliability. Surgical instruments demand seamless precision. Marine environments create severe corrosion challenges. Salt spray attacks weld seams aggressively. Seamless construction resists pitting corrosion better.

Food processing equipment follows ASTM A270 specifications. Sanitary applications demand smooth, clean surfaces. Both welded and seamless meet these requirements. Pharmaceutical manufacturing chooses seamless for critical piping. Contamination prevention requires seamless construction. Clean-in-place systems work better without weld seams.

Regulatory compliance drives material selection here. FDA, USDA, and industry standards specify requirements. Understanding these regulations ensures proper specification.

Material Grades and Standards for Welded and Seamless Tubing

Common Stainless Steel Grades

Grade 304 dominates general-purpose applications. It offers excellent corrosion resistance affordably. Most architectural and food-grade applications use 304. Grade 304L reduces carbon content below 0.03%. This prevents carbide precipitation during welding. Welded construction often specifies 304L.

Grade 316 adds 2-3% molybdenum for enhanced corrosion resistance. Marine and chemical applications choose 316. The cost premium is approximately 30% over 304. Grade 316L combines low carbon with molybdenum. It provides superior weldability and corrosion resistance. Medical and pharmaceutical industries prefer 316L.

Grade 321 contains titanium stabilization. This prevents intergranular corrosion at high temperatures. Exhaust and high-temperature applications use 321.

Grade 409 offers economical ferritic stainless. Automotive exhaust systems use 409 extensively. It provides adequate corrosion resistance at low cost.

ASTM Standards Comparison

ASTM A269 covers both welded and seamless tubing. It specifies general-purpose applications. Mechanical properties and testing requirements are identical.

ASTM A554 addresses mechanical tubing specifically. It includes both welded and seamless types. This standard emphasizes dimensional tolerances.

ASTM A312 applies to welded steel pipe. It focuses on process piping applications. Pressure ratings and weld testing appear here.

ASTM A213 specifies seamless boiler tubing. High-temperature service requirements drive this standard. It includes stringent mechanical property requirements.

Tensile strength requirements vary by grade. Grade 304 requires 75,000 PSI minimum. Grade 316 specifies similar strength levels.

Code Compliance and Industry Standards

ASME B31.3 Process Piping Code governs chemical plants. It specifies when seamless tubing is mandatory. Pressure and temperature combinations determine requirements. API standards control oil and gas applications. API 5L covers line pipe specifications. These standards often require seamless construction.

Pressure vessel codes mandate seamless for certain applications. ASME Section VIII specifies construction requirements. High-pressure vessels use seamless exclusively. Industry specifications sometimes override general standards. Nuclear, aerospace, and medical industries maintain stricter requirements.

Welded Pipe Connections and Installation Considerations

Joining Methods for Welded vs Seamless Tubing

Weld seam orientation matters during installation. Position the seam away from maximum stress points. This improves system reliability. Bending welded tubing requires careful planning. Keep the weld seam on the neutral axis. This prevents seam failure during forming.

Fusion welding works identically for both types. Orbital welding produces consistent, high-quality joints. TIG and MIG welding both apply. Compression fittings grip welded tubing effectively. The uniform wall thickness ensures proper sealing. Seamless tubing works equally well.

Threaded connections work with both tubing types. NPT and BSPT threads cut into material. Wall thickness must accommodate thread depth.

Fabrication and Workability

Formability differences affect complex fabrication. Annealed tubing bends more easily. ASTM A249/269 specifies annealed condition. Welding procedures remain standard for both types. Pre-heating requirements depend on grade and thickness. Post-weld heat treatment may be necessary.

Bending radii depend on wall thickness. Thin-wall tubing achieves tighter bends. Heavy-wall material requires larger radii. Tool requirements stay consistent between types. Standard tube benders, cutters, and welders apply. No specialized equipment is necessary.

Field modifications happen equally with both. Cutting, threading, and welding occur on-site. Welded tubing offers no disadvantage here.

Future Trends and Innovations in Tubing Technology

Advances in Welded Tubing Quality

Improved welding technology continues narrowing the performance gap. Laser welding produces increasingly uniform seams. Quality consistency improves year over year. Enhanced non-destructive testing catches defects earlier. Ultrasonic inspection runs continuously during production. Quality assurance becomes more robust.

New alloy developments improve weld zone properties. Metallurgical research reduces heat-affected zone weaknesses. Future welded tubing may match seamless performance. Automated production increases consistency dramatically. Robotic systems eliminate human error. Quality variations decrease significantly.

Seamless Tube Production Efficiency Improvements

Manufacturing innovations reduce traditional lead times. New extrusion technology speeds production. Cost reduction initiatives make seamless more competitive. Process improvements lower manufacturing expenses. The price gap shrinks gradually.

Expanded size range capabilities open new applications. Larger diameter seamless tubing becomes available. Heavy-wall options multiply. Sustainability and material efficiency trends affect both types. Recycled content increases in stainless production. Environmental concerns drive innovation.

Conclusion

Choosing between seamless vs welded tubing requires careful consideration of your specific application needs. Seamless tubing offers superior pressure capacity and structural integrity for critical applications. Welded tubing provides cost-effective solutions with excellent availability and dimensional consistency. The decision ultimately depends on operating pressures, budget constraints, and regulatory requirements. For expert guidance on selecting the right stainless steel tubing for your project, Profab Machine delivers precision fabrication solutions tailored to industrial specifications. Their expertise ensures you get optimal performance whether your application demands seamless strength or welded efficiency.

FAQ

When do engineers specifically choose seamless tubing over welded?

Seamless tubing is preferred for high-pressure systems, fatigue-critical applications, and safety-sensitive industries such as hydraulics, oil & gas, and certain chemical processes.

Which type is easier to source with short lead times?

Welded stainless tubing is generally easier to source, available in more sizes, and offers shorter lead times compared to seamless tubing.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints

The Most Common Boat Linkage Failures