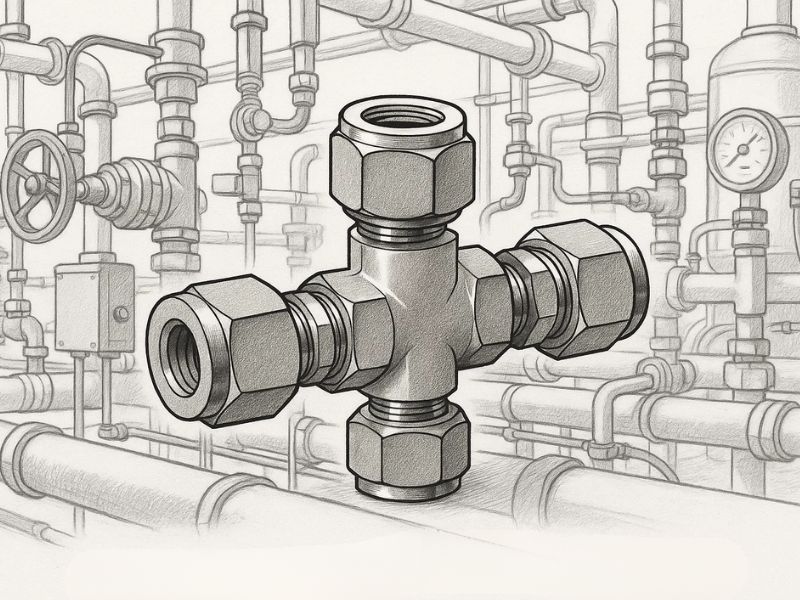

Stainless Steel Tube Fittings

Stainless Steel Pipe Fittings Supplier in China

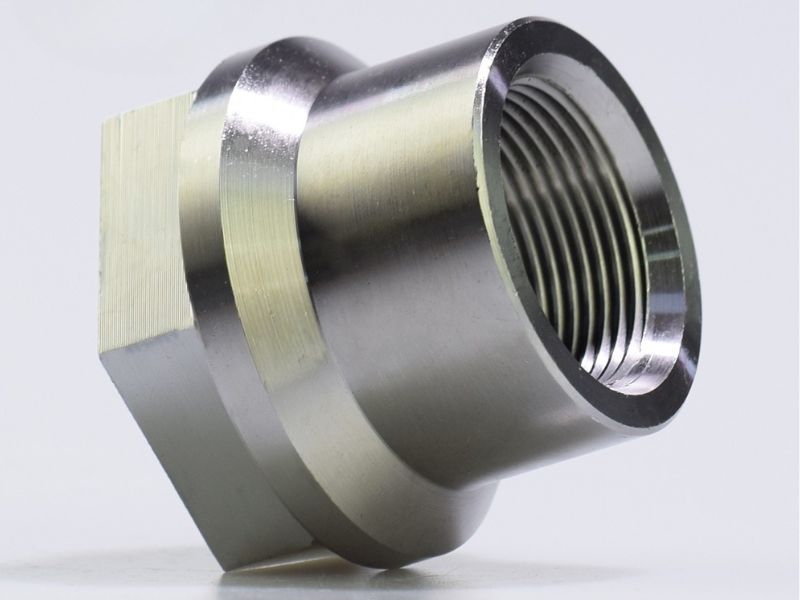

Stainless steel tube fittings is a critical component in a fluid transfer system. Its core function is to act as a critical node for connection, sealing and control.Profab utilizes a graded process control for the surface treatment of stainless steel tube fittings. From degreasing and pickling to mechanical and electrolytic polishing and finally passivation and in-line cleaning. This ensures that the surfaces of these stainless steel tube fittings are free of free iron, burns and residues.

Profab Machine can realize different finishes from matte to mirror as per customer’s requirement. We issue surface roughness (Ra) and specular reflectivity test reports according to specified standards.Profab ss tube fittings meet the stringent requirements of hygiene and corrosion resistance in the food, pharmaceutical and chemical industries.

- Excellent corrosion resistance

- Reliability and long life reduce long-term costs

- High temperature and high pressure tolerance

- Easier maintenance and servicing

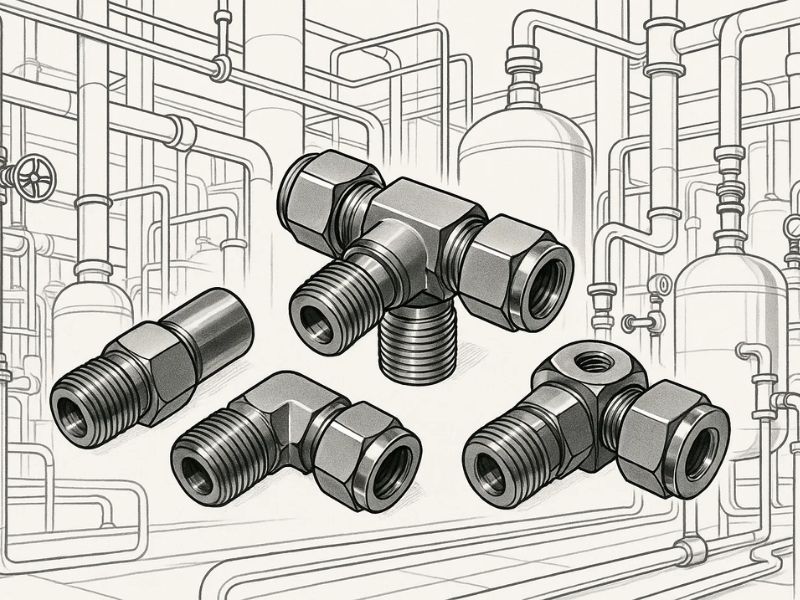

Variety of Applications For SS Tube Fittings

Stainless steel pipe fittings play an integral role in several key industries due to their superior performance. Profab ss tube fittings support prototype evaluation, process validation, and small lot scale-up production. We also support customized packaging and labeling, and Profab Machine guarantees consistent appearance and performance when delivered at scale, reducing your inspection costs and project risk.

Pharmaceuticals & Biotechnology

The pharmaceutical and biotech industries demand the highest fluid purity and traceability. Profab 316L ss tube fittings often undergo electropolishing. This process achieves extremely smooth internal surfaces.

Food & Beverage

In the food and beverage industry, piping systems must meet the highest hygiene and cleanliness standards. 304 and 316L ss pipe fittings have smooth surfaces and inert composition. They are easy to clean and resist bacterial growth.

Chemical & Petrochemical

Chemical and petrochemical plant pipelines carry many corrosive fluids. The excellent corrosion resistance of 316L ss tube fittings is crucial.

Oil & Gas

Oil and gas pipelines face high pressure, strong vibration, and corrosive fluids. 316/316L pipe fittings are vital in these conditions. They provide excellent sealing, corrosion resistance, and vibration tolerance.

Why Choose PROFAB

Profab has more than 10 precision production lines. The factory is equipped with 5-axis CNC, laser cutting, welding, and various surface treatment equipment. The wide range of automation and CNC equipment allows for efficient fulfillment of high-volume orders as well as the flexibility to switch production lines to meet small batch customization needs.

- 20 Years Of Professional Manufacturing Experience

- Comprehensive solutions, not just products

- Customer-centric, simplified quotation and communication processes

- Reliability and sustainability

- Immediate response, regardless of project size

| Connection Method | Ease of installation | Reusability | Sealing reliability | Vibration resistance | Cost | Main application scenarios |

| Card Sleeve Type | High | High | Very high | Very high | Middle | High-precision instruments, hydraulic systems, analytical equipment |

| Threaded | High | High | Medium (sealant dependent) | Medium | Low | General pipelines, water conservancy, chemical industry (non-critical) |

| Welding | Low (requires professional skills) | No | Very high | Very high | High | Large-scale pipeline projects, high-pressure/high-temperature critical systems |

| Press-fit | Very high | No (O-ring needs to be replaced) | Very high | Very high | Middle | Civil systems such as drinking water, heating, and gas |

Maximum Allowable Working Pressure (MAWP) is the highest internal pressure that a fitting can safely withstand at a given temperature.

The following tables, based on the ASME B31.3 and B31.1 codes, provide the maximum allowable working pressures for different sizes of ss pipe fittings at room temperature (22∘C).

Size (OD) | Wall Thickness (inches) | Normal Working Pressure(psig) | 537°C(1000°F)Temperature Coefficient | High Temperature Working Pressure(psig) |

1/4″ | 0.035 | 4400 | 0.76 | 3344 |

1/2″ | 0.035 | 2600 | 0.76 | 1976 |

1/2″ | 0.049 | 3700 | 0.76 | 2812 |

3/4″ | 0.049 | 2400 | 0.76 | 1824 |

1″ | 0.049 | 1800 | 0.76 | 1368 |

There is a negative correlation between working pressure and temperature. As the temperature increases, the mechanical strength of the stainless steel material gradually decreases, which leads to a weakening of its pressure-bearing capacity. Therefore, the MAWP at room temperature must be depressurized to ensure safety in high-temperature environments.

The user is required to multiply the MAWP at room temperature by the corresponding depressurization factor to obtain the true maximum working pressure at a given high temperature.

For example, a 316 stainless steel fitting with a working pressure of 2600 psig at ambient temperature and a temperature coefficient of 0.76 at 537∘C would reduce the MAWP to 1976 psig.