Stainless Steel Bushing

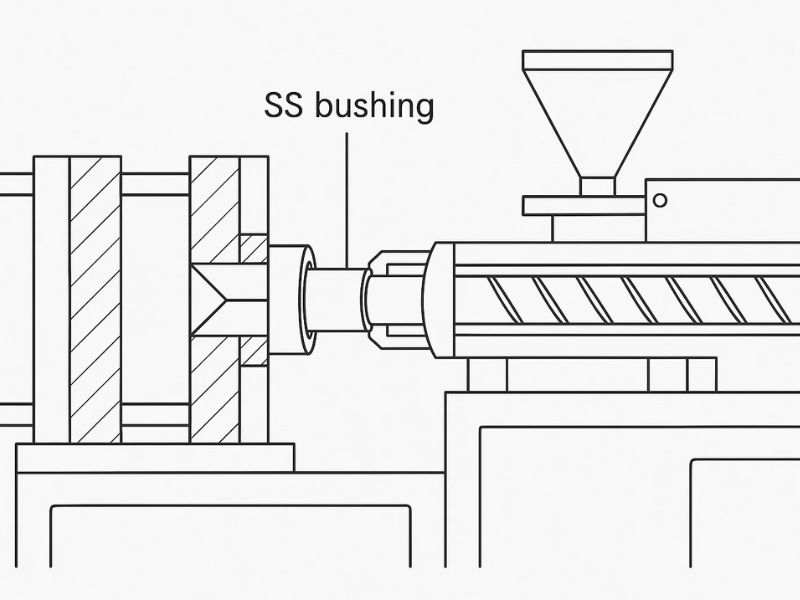

Profab stainless steel bushings are CNC machined with high precision and standardized heat treatment to provide excellent wear and corrosion resistance for a wide range of machinery and equipment.

Stainless Steel Bushing Manufacturer in China

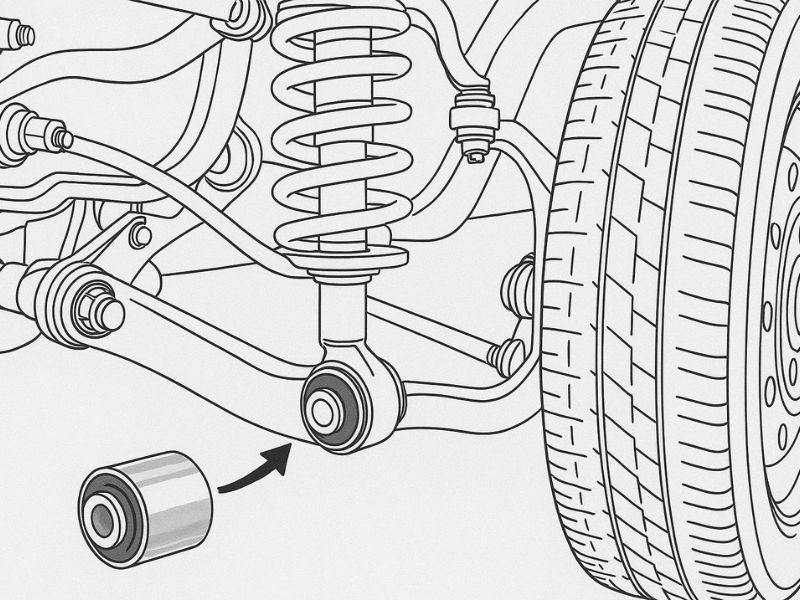

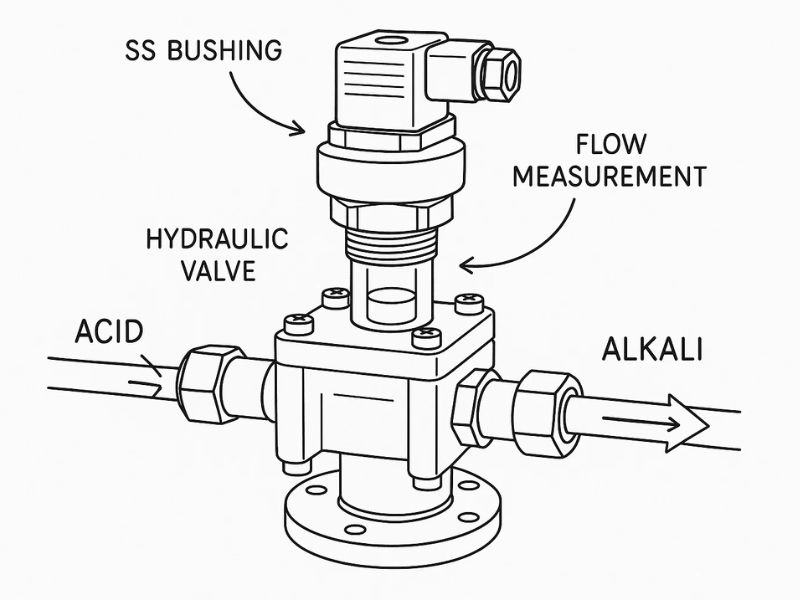

The core function of stainless steel bushings is to reduce friction between two moving parts and prevent wear. They are primarily used to provide the necessary support and guide movement in mechanical systems. A minimum of 10.5% chromium content in stainless steel creates a self-repairing oxide layer on the surface. This provides the bushing with unrivaled protection. The self-lubricating properties and multi-layer compound construction also make stainless steel bushings suitable for use in harsh environments.

Profab Machine is a professional stainless steel bushing processing factory. We offer various types of stainless steel bushings, such as Flange Bushings, Ball Bushings, Grooved Bushings, Composite Bushings, 304 Stainless Hex Bushings, 316 Stainless Hex Bushings, and so on.

- Excellent corrosion resistance

- High hardness and low coefficient of friction

- Dimensional accuracy ±0.01 mm

- Easy to install and maintain

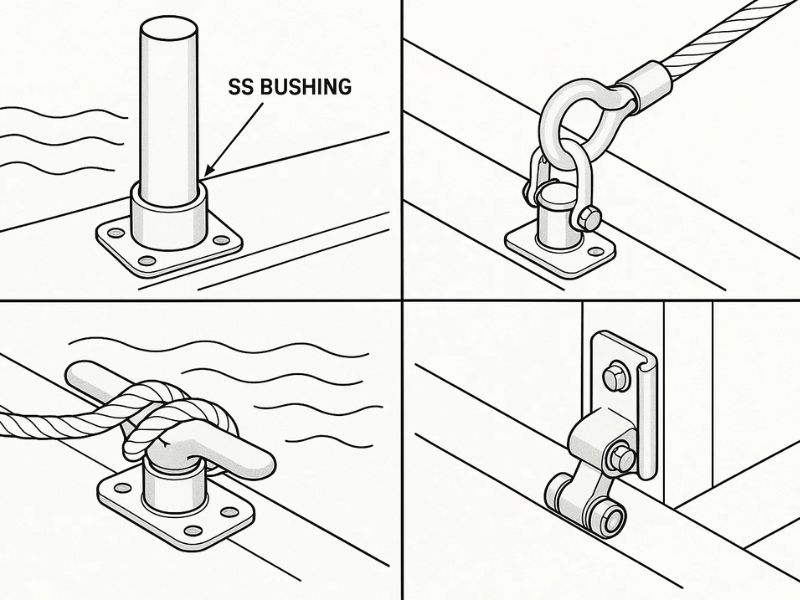

Variety of Applications For SS Bushing

Why Choose PROFAB

From material selection to post-processing, one-stop solution, strict quality control, rapid response to customer needs:

- 20+ years of industry experience

- Complete in-house machining capacity: turning, milling, heat treatment

- Flexible small batch customization

- ISO 9001 certified

- Global shipment, professional technical support

| Brand | Main ingredient differences | Corrosion resistance | Tensile strength (approx. MPa/Ksi) | Maximum operating temperature (approx. °C/°F) | Ideal bushing applications | Wear resistance description |

| 304 stainless steel | Standard “18/8” chrome-nickel alloy | Good overall corrosion resistance, high rust resistance, suitable for general corrosive environments | 621 MPa (90 Ksi) | 870 °C (1,679 °F) | General machinery, food and beverage processing (mild environment), bearing seats | The wear resistance is average when used alone, but it can be improved when combined with other materials. |

| 316 stainless steel | Add 2-3% molybdenum | Excellent corrosion and pitting resistance, especially in high chloride environments | 579 MPa (84 Ksi) | 800 °C (1,472 °F) | Marine industry, chemical processing, pharmaceuticals, high temperature environments, bearing seats | The wear resistance is average when used alone, better than 303 |