Solar Energy

Source Custom Parts For Solar Energy

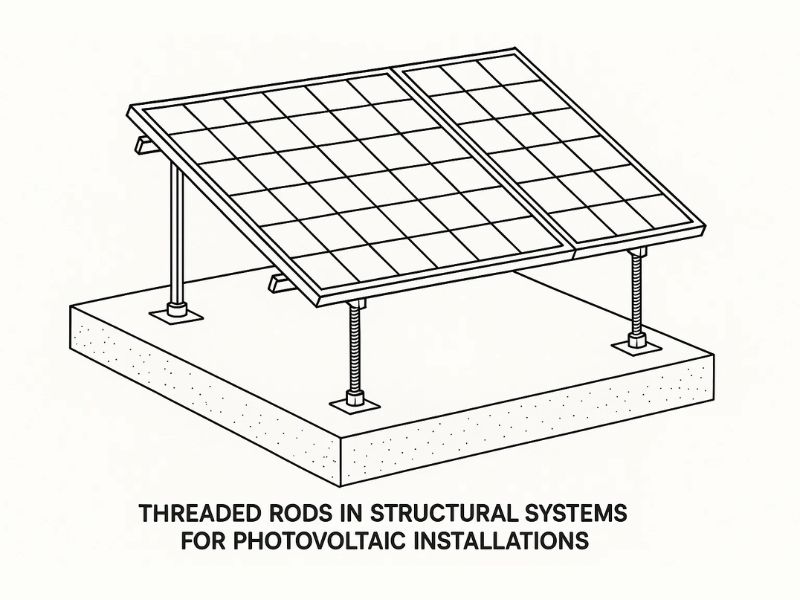

The solar industry puts forward extremely high technical requirements for stainless steel fittings, which not only require excellent structural strength to withstand prolonged outdoor loading and wind-pressure impacts, but also must have excellent corrosion resistance to withstand high humidity, strong ultraviolet rays, salt spray, and other harsh climatic conditions.

Contact Profab to boost your project!

Solar Energy Manufacturing Capabilities

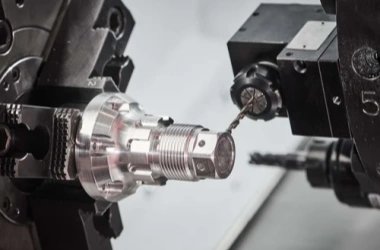

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Solar Energy

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Solar Energy Experts Choose Profab

Profab has a complete production system from raw material procurement, CNC machining, welding and assembly to surface treatment and precision testing. We specialize in serving the aerospace, automotive, machinery, and agricultural industries that demand the highest levels of performance and reliability.

Precision Machining of Profab

Components in solar energy systems require long-term mechanical movement or precise positioning, which requires very high dimensional accuracy and fit tolerances of the accessories.Profab has advanced CNC machining equipment and strict process flow to ensure the precise positioning and stable operation of each component in the system. High-precision turning, milling, drilling, and automated assembly technologies enable batch consistency and high assembly efficiency. This is particularly suitable for solar systems with multi-axis linkages and dynamically adjustable structures.

Multiple Surface Treatment Capabilities

Accessories in the solar industry need to be exposed to harsh outdoor environments for long periods of time. If the surface is not properly treated, problems such as corrosion, passivation failure, and loosening of mechanical joints can easily occur, thus affecting the structural stability and lifetime of the entire PV system.

Profab offers a wide range of professional-grade surface treatments, including pickling, passivation, electrolytic polishing, sandblasting, and anticorrosive coatings that effectively enhance the weathering and corrosion resistance of stainless steel parts. This not only extends service life, but also facilitates subsequent assembly or welding operations.

FAQ

Will it rust if used outdoors for a long time?

The use of high-quality stainless steel and with electropolishing or passivation treatment can effectively improve the corrosion resistance life.