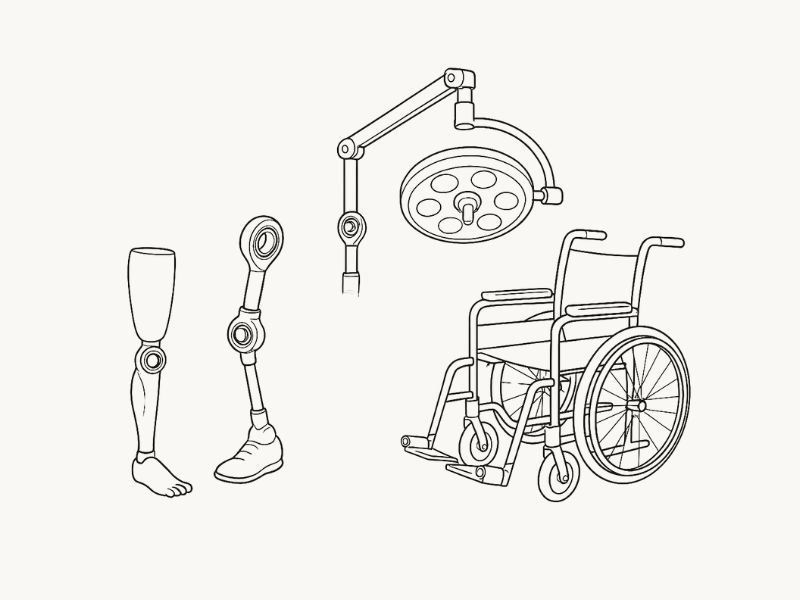

Medical

Source Custom Parts For Medical Industry

As medical equipment requires a high degree of surface finish, precision, material safety and corrosion resistance, Profab is a one-stop solution for customers in the medical industry with extensive experience in precision machining of stainless steel. Our CNC equipment ensures the precision and consistency of the parts, and a variety of clean-grade surface finishes are available to meet the stringent quality standards of the medical industry.

Contact Profab to boost your project!

Medical Industry Manufacturing Capabilities

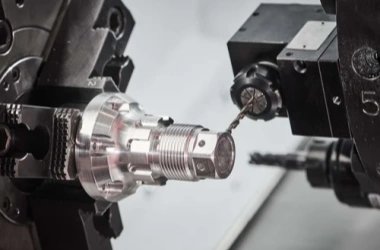

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Medical Industry

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Medical Experts Choose Profab

The requirements for stainless steel parts for medical devices are much higher than those for general industrial use. Not only do they need to be clean, accurate and corrosion-resistant, but they also need to be structurally stable over long periods of time. profab’s high standard stainless steel parts for medical devices meet the industry’s requirements to ensure the safety of the equipment. We understand that every detail of a medical product is a matter of life and death, and we always respond to high standards with rigorous workmanship.

Professional Surface Polishing Process

Profab utilizes a high standard of surface finishing processes such as electrolytic polishing and mirror polishing. It is designed to create a smooth, dead-end, easy-to-clean surface structure for medical-grade stainless steel components. The precision-controlled polishing process improves the corrosion and antimicrobial resistance of the metal surface, adapting it to the needs of the medical environment.

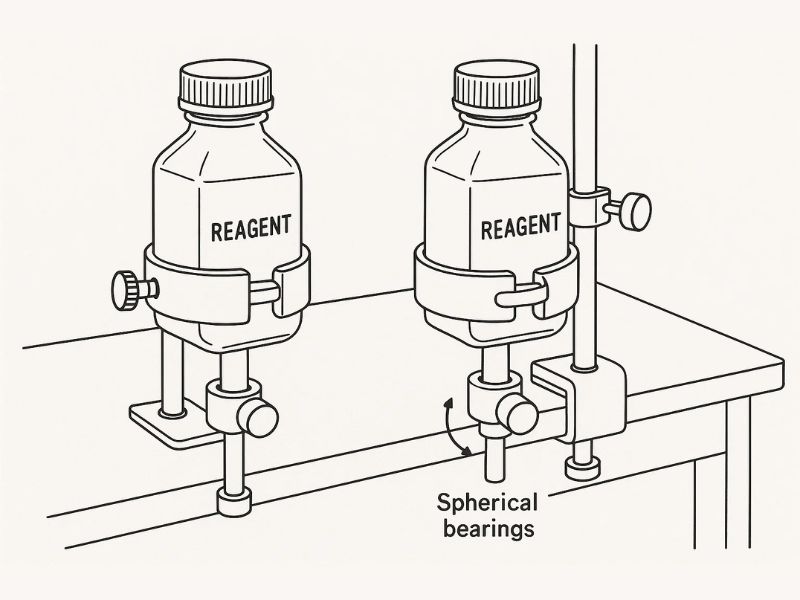

Compliant And Reliable Raw Materials

Profab selects medical grade stainless steel. Commonly used grades include 304, 316L, etc., with excellent corrosion resistance, biocompatibility and stable physical structure. All raw materials are sourced from certified suppliers with whom we have a longstanding relationship, ensuring product traceability and regulatory compliance.

FAQ

Can the surface be treated to sterile standard?

We can provide electrolytic polishing and mirror surface treatment, the surface cleanliness can reach the standard for medical equipment use, easy to clean and sterilize.