Marine

Source Marine Grade Stainlss Parts From Profab

Profab understands the rigors of the marine environment. From the selection of raw materials to precision machining and surface treatments, we meet the standards for heavy-duty corrosive applications. Upgraded marine grade stainless steels are used and tested for high fatigue strength. Our stainless components ensure long-term stability under harsh environments.

Contact Profab to boost your project!

Marine Industry Manufacturing Capabilities

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Marine Industry

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Marine Experts Choose Profab

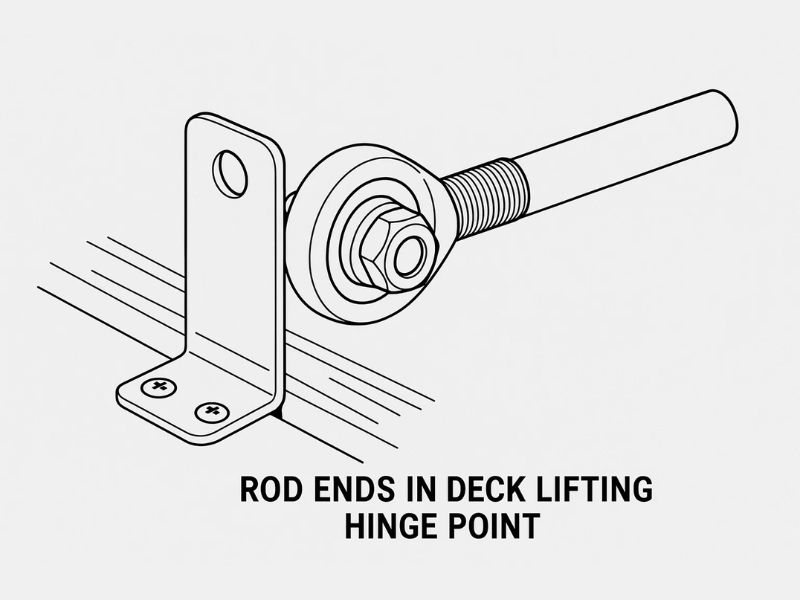

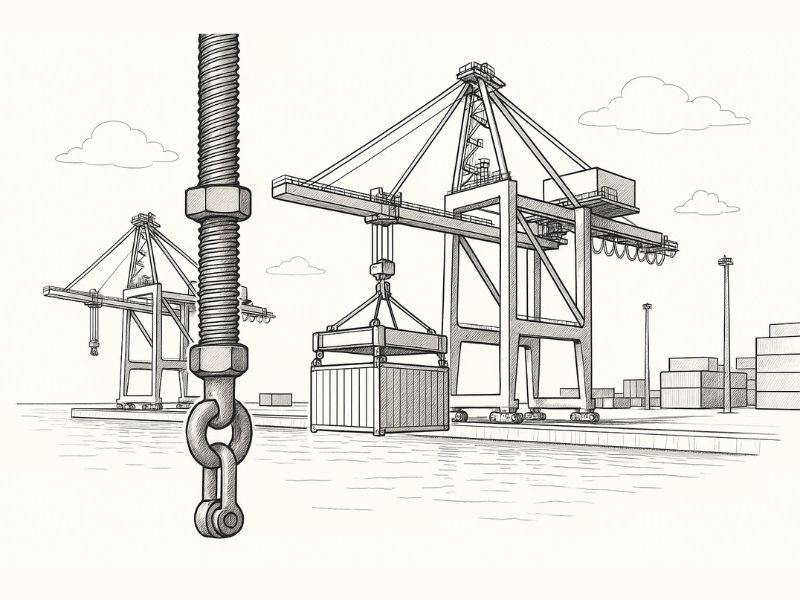

Profab offers stainless steel fittings solutions designed specifically for the marine industry. We use high-performance stainless steel suitable for marine equipment, and support electrolytic polishing, passivation and other surface treatment to effectively enhance the long-term service life of the fittings.Profab can quickly respond to the needs of shipyards, port equipment manufacturers and other types of customers’ projects, and is a reliable partner for fittings in your marine engineering.

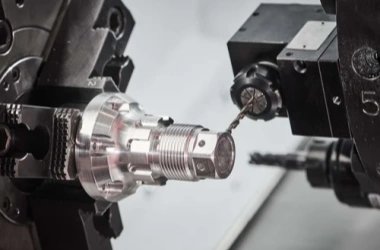

Precision CNC Machining

Profab has a mature CNC machining system, equipped with multi-axis CNC machining centers and professional stainless steel machining tools, specializing in the precision manufacturing of complex structural parts. For the working environment of equipment in the maritime industry, Profab’s CNC process can provide high-quality parts that can withstand small-lot customization and fast delivery, which can help the stable operation of maritime projects.

Our Testing Equipment

Profab has a perfect testing system, from raw materials to finished products to ship the whole process of quality control. For high corrosion and high vibration marine equipment, there are special dimensional deviation tests and assembly fit tests to ensure the long-term stable operation of the whole batch of products in the harsh marine environment.

FAQ

Marine equipment has requirements on the strength of fittings, what tests have the products gone through?

We support pre-factory testing such as tensile strength, fatigue, dimensional accuracy, etc. We can also provide third party certification reports upon request to ensure that all fittings meet the standards of classification societies or heavy-duty working conditions.

Maritime projects usually have tight lead time, how long is your lead time?

Regular specification products can be delivered quickly, and the delivery time for non-standard products is about 7-20 days depending on the complexity. We have stable inventory and flexible production capacity to adapt to the rapid response demand of engineering projects.