- By Profab /

- September 22, 2025

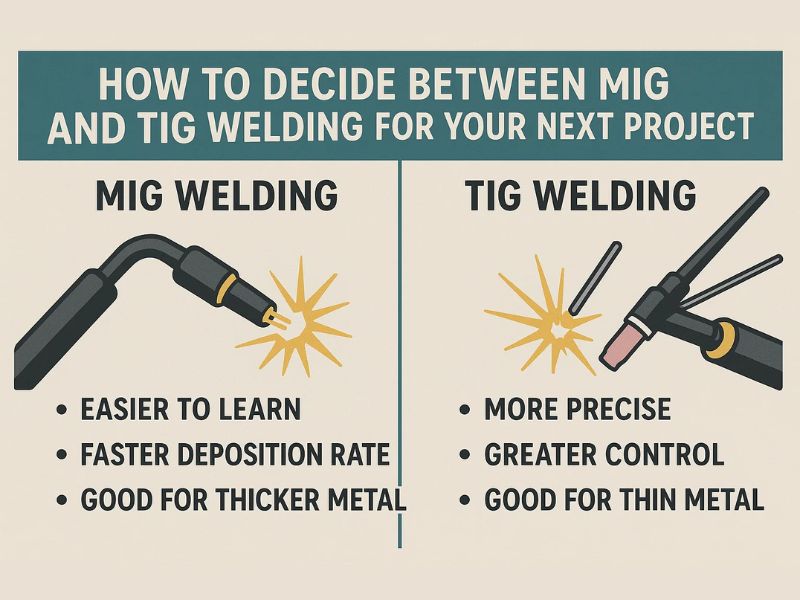

The selection between MIG and TIG welding is an engineering and economic decision. You should: balance production speed with welding precision; consider initial cost versus long-term quality; protect the unique metallurgical properties of stainless steel, especially its corrosion resistance. MIG welding is exceptionally well-suited for high-volume, structural fabrication on thicker materials. Conversely, TIG welding is the preferred and often mandatory choice for critical, high-purity.

Table of Contents

What Is MIG Welding

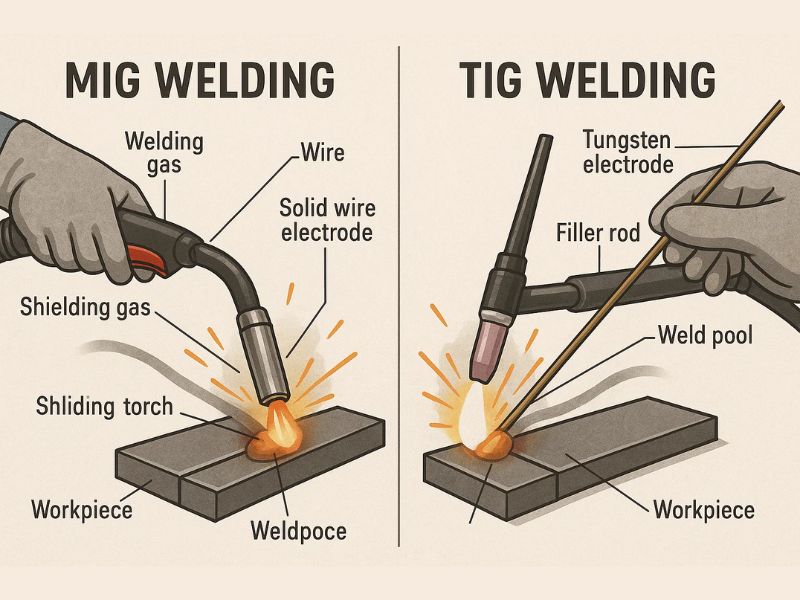

The equipment for MIG welding is relatively straightforward, consisting of a power source, a wire feed unit, the welding gun itself, and a shielding gas supply. The wire electrode is consumable, meaning it is melted and becomes part of the final weld. For most stainless steel applications, the process uses a Direct Current Electrode Positive (DCEP) polarity, which ensures arc stability and promotes sufficient penetration into the base metal.

How MIG Works

MIG welding uses a wire electrode that feeds automatically through a welding gun. You hold the gun and guide it along the seam. The wire melts and joins the metal pieces. This process works well for beginners because you only need to focus on moving the gun smoothly. MIG welding is popular for large projects and thick metals.

What Is TIG Welding

The TIG welding system includes a power source, a TIG torch with its non-consumable tungsten electrode, and a shielding gas supply. The tungsten electrode and the filler rods are distinct consumables. A key feature of TIG welders is their versatility, with the option to use both AC and DC power sources. However, for welding stainless steel, a DC machine with electrode negative polarity (DCEN) is typically used, as this concentrates the heat at the workpiece, promoting proper penetration. Water-cooled torches are often preferred or required for TIG applications to prevent overheating.

How TIG Works

TIG welding uses a tungsten electrode and a separate filler rod. You control the torch with one hand and feed the filler rod with the other. This method gives you more control over the weld. TIG welding works best for thin metals and projects that need a clean, precise finish. You need steady hands and good timing to master TIG welding.

MIG vs TIG Welding

Skill and Learning Curve

TIG welding requires a high degree of skill, coordination, and manual dexterity. The process is a dual-hand operation, with one hand managing the torch and the other manually feeding the filler rod. Mastering this requires extensive training and practice.

MIG welding is widely regarded as easier to learn and master, and is often referred to as the “hot glue gun” of welding. The semi-automatic nature of the process simplifies the technique, allowing beginners to quickly produce strong, usable weld beads with minimal training.

Weld Strength and Penetration

TIG welding Display

MIG welding Display

TIG welds are widely considered to be superior in terms of strength and penetration. The process’s narrow, focused arc allows for deep and precise fusion, resulting in a joint with a high level of integrity. Properly executed TIG welds also have a lower defect rate.

While MIG welds can also be strong and durable, they generally produce a broader and less-focused arc, which can result in shallower penetration. The strength and penetration of a MIG weld can be significantly improved by preparing the joint with a V-groove. While both methods can produce a strong weld, the inherent control and focus of the TIG process make it the de facto choice for applications where weld integrity is a critical requirement.

Speed and Efficiency

MIG welding is much faster than TIG welding. TIG is a notably slow process due to the manual, meticulous nature of adding filler material and controlling the weld. TIG welding typically has low deposition rates, averaging between 1 and 2 kilograms per hour. This makes TIG unsuitable for long, continuous welds and large-scale production runs.

Conversely, MIG welding is designed for high productivity. Its continuous wire feed allows for significantly faster welding speeds, with deposition rates ranging from 3 to 8 kilograms per hour. This results in a deposition rate that is three to four times faster than TIG, making MIG the clear choice for high-volume manufacturing and projects that require long weld runs.

Weld Strength and Finish

TIG welding creates stronger and cleaner welds. Studies show TIG welds have up to 25% higher tensile strength than MIG welds. MIG welds are strong but may have a larger heat-affected zone. TIG welds look smoother and have fewer defects. If you need a weld that looks good and lasts long, TIG welding is the way to go.

Material Thickness

- TIG Only: For very thin materials (0.5 mm to 1.5 mm), TIG is the only viable option. MIG’s high heat input at this thickness can easily cause burn-through, leading to costly rework or scrap.

- TIG Preferred: For typical housings (1.5 mm to 3 mm), TIG remains the preferred choice due to the importance of heat control in preventing distortion.

- Either Process: For materials ranging from 3 mm to 6 mm, both processes are viable, and the choice can be made based on other factors like speed and aesthetics.

- MIG Preferred: For structural components 6 mm and thicker, MIG becomes the more efficient choice. Its speed and high deposition rate allow for full penetration in a single pass, while TIG would require multiple passes, which would increase both time and heat input.

Visual Aesthetics and Post-Processing Requirements

For applications where the finished appearance is a primary concern, TIG welding is the undisputed choice. TIG welds are known for their clean, uniform, and aesthetically pleasing finish with minimal to no spatter. The iconic “stack-of-dimes” appearance of a well-executed TIG weld is highly prized and typically requires only light polishing to remove any minor heat tint.

In contrast, MIG welds on stainless steel are generally less visually appealing, with a rougher appearance and a greater risk of spatter. The high heat input can also lead to significant discoloration, which necessitates extensive post-processing. This post-weld cleanup often involves aggressive grinding, chemical cleaning, and passivation, a process that can be time-consuming, expensive, and may compromise the dimensional tolerances of precision parts.

Applications

Aerospace and Critical High-Purity Applications

For industries such as aerospace, TIG welding is the dominant and often mandated process. The demand for flawless welds, minimal defects, and precise control over the heat-affected zone is a non-negotiable safety and quality requirement for components like aircraft engine parts. The ability to repair minor defects with TIG, rather than scrapping a costly part, also represents a critical economic advantage. The process’s high precision and low defect rate align perfectly with the stringent quality standards of these industries.

Structural and Industrial Fabrication (Heavy Gauge)

For large-scale industrial and structural applications, such as frameworks, pressure vessels, and heavy machinery, MIG is the preferred process. The priority in these applications is speed, efficiency, and high deposition rates. Aesthetics are often a secondary concern since the welds are frequently hidden or coated. The ability of MIG to achieve full penetration in a single pass on thicker materials provides a significant advantage in productivity and cost-effectiveness. Pulsed MIG offers an excellent middle ground, providing improved weld quality for mid-volume runs that require a cleaner finish than standard MIG.

Food and Beverage, Medical, and Sanitary Welding

TIG welding is the standard for sanitary applications in the food, beverage, and medical industries. The term “sanitary welding” itself is a testament to the process’s importance. TIG’s ability to maintain the corrosion resistance of stainless steel is paramount, as the finished products are exposed to harsh cleaning chemicals and must resist bacterial growth. TIG’s precise heat control prevents chromium carbide precipitation, ensuring the long-term integrity of the welds. Its clean, low-spatter welds are critical for preventing contamination traps and ensuring a hygienic surface.

Architectural and Aesthetic Projects

For architectural and artistic projects where the visual appeal of the final product is paramount, TIG is the clear choice. Whether for high-end stainless steel railings, custom countertops, or artistic sculptures, TIG’s ability to produce clean, spatter-free welds with the iconic “stacked dimes” appearance is a significant advantage. These projects prioritize finish quality over speed and benefit from the precision and control that TIG provides.

The choice between MIG and TIG for stainless steel is primarily a matter of weighing the high throughput efficiency of MIG against the accuracy and quality of TIG. Don’t let the complexities of stainless steel welding compromise your project. At Profab Machine, our certified welders are experts in both MIG and TIG processes. We understand the nuances of different stainless steel grades and select the right technique to ensure your project’s integrity, aesthetics, and long-term durability.

Whether your job requires the precision of TIG for a critical sanitary application or the efficiency of MIG for a large structural build, we deliver flawless results. Contact Profab Machine today for a quote, and let our craftsmanship bring your project to life.

FAQ

What is the main difference between TIG welding and MIG welding?

TIG welding uses a tungsten electrode and gives you more control for precise, clean welds. MIG welding uses a wire feed and works faster for bigger projects. You choose based on your need for speed or precision.

Which process is better for welding stainless steel?

TIG welding vs MIG welding for stainless steel depends on your needs. TIG welding gives you a cleaner, stronger weld. MIG welding works faster and is better for large or less visible joints.

Which welding method is easier for beginners?

MIG welding is easier for beginners. The wire feeds automatically, so you only guide the gun. TIG welding takes more practice because you control both the torch and filler rod.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints