- By Profab /

- January 28, 2026

Understanding how standoffs and spacers function in marine applications prevents costly failures. Standoff spacers provide the essential spacing, electrical isolation, and vibration resistance that marine electronics require. These small components create precise gaps between circuit boards and mounting surfaces. They prevent electrical shorts while allowing airflow for cooling.

Most importantly, threaded standoffs spacers lock assemblies firmly despite constant motion and vibration. This comprehensive guide demonstrates practical applications, installation methods, and problem-solving techniques. Let’s have a look.

Table of Contents

Functions of Standoff Spacers in Marine Equipment

Securing Engine Control Modules and Power Distribution Boards

Engine bay environments subject electronics to extreme vibration levels. Diesel engines generate 5-15 Hz vibration continuously during operation. High-speed gasoline engines produce 20-50 Hz frequencies. Only threaded standoff spacers provide adequate vibration resistance in these conditions.

Electronic control modules (ECMs) manage fuel injection, ignition timing, and emissions control. They mount directly above engines where vibration intensity peaks. M5 or M6 coarse-thread standoffs with lock washers prevent loosening. Thread-locking compounds rated for 150°C temperatures ensure permanent retention.

Power distribution boards carry 50-400 amps requiring electrical isolation from grounded enclosures. Direct contact creates dangerous short circuits and potential fires. Stainless steel spacers standoffs maintain 8-12mm isolation gaps consistently. They prevent electrical contact while supporting heavy bus bars.

Thermal management spacing becomes critical for power electronics and switching components. MOSFET switches, rectifiers, and voltage regulators generate substantial heat. Standoffs create convective airflow paths removing heat effectively. Longer 20-25mm standoffs improve cooling in high-current applications.

Application | Standoff Size | Material | Thread Type | Typical Height |

GPS Receiver | M3-M4 | 316 Stainless | Female-Female | 12-15mm |

Radar Display | M4-M5 | 316 Stainless | Male-Female | 15-20mm |

Engine ECU | M5-M6 | 316 Stainless | Female-Female | 15-25mm |

Power Distribution | M6-M8 | 316 Stainless | Male-Female | 10-15mm |

Marine Lighting Systems and Junction Box Assemblies

LED driver boards in moisture-resistant light fixtures require elevated mounting preventing condensation contact. Marine navigation lights operate in temperature extremes causing condensation formation. Standoffs lift boards 8-12mm above fixture bases allowing drainage.

Junction box component spacing prevents short circuits from condensation accumulation. Relay modules, terminal blocks, and breakers need adequate separation. Stainless steel threaded spacer components maintain spacing despite box flexing. They resist corrosion from condensation exposure indefinitely.

Navigation light assemblies mount in exposed masthead and stern locations. They endure direct saltwater spray and UV radiation continuously. 316 stainless steel standoffs withstand these conditions for 5-10 years. Hex profiles allow removal with standard marine toolkits.

Underwater lighting installations demand maximum corrosion resistance and sealing integrity. Submersible LED lights use potted assemblies with sealed standoff penetrations. Bronze or 316 stainless standoffs prevent galvanic corrosion. Silicone potting compounds encapsulate all connections completely.

Tips

Masthead navigation light electronics mounting requires M3x10mm standoffs minimum. They elevate PCBs above condensation drainage holes. Anti-seize compound on threads prevents galling during service.

Communication Equipment and Antenna Mounting Applications

VHF radio chassis mounting uses stainless steel spacers standoffs to provide both structural support and electrical grounding. Radio chassis require solid grounding for optimal RF performance. Stainless steel standoffs create low-resistance ground paths. They maintain electrical continuity despite vibration and corrosion.

AIS transponder installations require precise grounding and isolation simultaneously. Antenna connections need grounding for lightning protection. Power supply circuits require isolation to prevent ground loops. Mixed standoff materials achieve both requirements effectively.

Satellite communication terminal electronics support structures endure extreme weather exposure. SATCOM domes mount on flying bridges and hardtops. Electronics boxes inside use corrosion-resistant standoff mounting. 316 stainless steel withstands condensation and temperature cycling.

Weather-resistant standoff solutions for exposed antenna amplifiers combine sealing and corrosion protection. Amplifiers mount near antennas minimizing signal loss. Sealed enclosures use gasketed standoff assemblies. O-rings at each standoff prevent water ingress.

Application Case

Marine SSB radio installations in blue-water cruising yachts require robust grounding. M5x20mm brass standoffs provide excellent conductivity. They connect radio chassis to vessel ground systems. Proper grounding reduces static noise and improves transmission range.

Bilge Pump Controls and Automatic Float Switch Systems

Standoff mounting elevates pump controller electronics in high-humidity bilge environments. Controllers mount inside sealed enclosures above potential water levels. Standoffs create 15-25mm clearance ensuring water cannot reach circuits. Ventilation holes allow moisture escape without water entry.

Elevation requirements prevent water contact with control circuitry during pump operation. Bilge water contains oils, fuels, and contaminants. Even small amounts damage electronics permanently. Adequate standoff height provides safety margin during extreme conditions.

Stainless steel spacers standoffs suit submerged sensor mounting brackets perfectly. Float switches and level sensors operate partially submerged continuously. 316 stainless steel resists corrosion indefinitely. Threaded connections maintain integrity despite constant submersion.

Anti-vibration standoff selection addresses pump-induced oscillation environments. Centrifugal pumps generate 10-30 Hz vibration during operation. Coarse-thread standoffs with lock washers prevent loosening. Rubber isolation washers reduce vibration transmission.

Material Selection for Marine Environment Durability

Why Stainless Steel Spacers Standoffs Dominate Marine Applications

316 marine-grade stainless steel provides superior corrosion resistance in saltwater immersion. The 2-3% molybdenum content creates protective oxide layers. These layers self-heal when scratched maintaining corrosion protection. 316 stainless survives continuous saltwater exposure indefinitely.

Salt spray testing standards verify marine hardware corrosion resistance objectively. ASTM B117 specifies 96+ hour continuous salt fog exposure. 316 stainless steel shows zero red rust after standard testing. 304 stainless develops surface rust within 48 hours.

Real-world performance data confirms laboratory test results. Commercial fishing vessels operating 300+ days annually provide harsh testing. 316 stainless standoffs last 5-10 years without replacement. 304 stainless requires replacement within 2-3 years.

Comparison of Alternative Materials for Standoff Spacers

Brass Spacer

Brass conducts electricity 15-20 times better than stainless steel. Radio equipment grounding requires low-resistance paths. Brass standoffs provide 0.15-0.20 ohm resistance versus 0.90-1.20 ohms for stainless.

Naval brass contains 60% copper and 40% zinc with 0.75% tin. The tin addition prevents dezincification in saltwater. Standard brass loses zinc leaving porous copper. Naval brass maintains structural integrity for 10+ years.

Silicon Spacer

Silicon bronze offers superior corrosion resistance compared to brass alloys. It contains 96% copper with silicon and manganese additions. Silicon bronze matches 316 stainless for saltwater resistance. It provides excellent electrical conductivity simultaneously.

Aluminum Spacer

6061-T6 aluminum provides exceptional strength-to-weight ratios for above-deck installations. It weighs 35% as much as steel with 60% of the strength. Racing sailboats and performance vessels benefit significantly. Weight reduction improves speed and fuel efficiency.

Nylon Spacer

Nylon 6/6 absorbs 2.5-3.5% moisture by weight. This absorption causes 0.3-0.8% dimensional growth. Standoffs loosen as they swell. UV degradation destroys plastics in sun-exposed deck installations within months. Nylon becomes chalky and cracks. Polycarbonate yellows and loses transparency.

Tips

Alternative materials provide electrical insulation when required: ceramic, fiberglass-reinforced phenolic, or PEEK. Ceramics resist moisture and UV completely. Phenolics absorb minimal moisture. PEEK costs more but performs excellently.

Understanding how standoff spacers function in marine equipment applications prevents costly failures and ensures reliable vessel operation. From navigation electronics requiring precise spacing and vibration isolation to engine controls demanding robust corrosion-resistant mounting, proper standoff selection makes the difference between years of reliable service and frequent expensive repairs. Profab Machine provides a wide range of standoff spacers in various sizes and materials. If you cannot find the specific model you need, we fully support custom manufacturing from your drawings. Please contact Profab Machine for high-quality fastening solutions tailored to your vessel.

FAQ

What is the best material for standoff spacers in a saltwater environment?

316 spacers is the best option for its superior pitting resistance. For non-load-bearing electrical isolation, Nylon or ABS spacers are preferred because they are completely immune to saltwater corrosion and prevent metal-to-metal contact.

How do spacers help with heat management in marine power systems?

Marine compartments are often cramped and poorly ventilated. Standoffs lift components like inverters or charge controllers off the bulkhead, allowing heat to dissipate from the back of the unit, which extends the lifespan of the electronics.

Send Inquiry Now

Related Resource

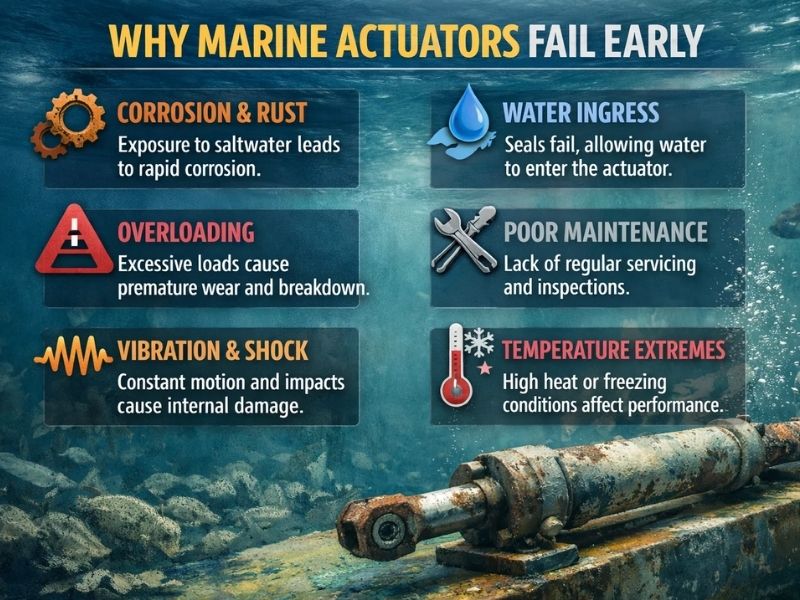

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them

The 3 Most Corrosion-Prone Parts of Hydraulic Cylinder