Food

Source Food Grade Stainlss Parts From Profab

Stainless steel components for food-grade equipment must not only be corrosion-resistant, but also easy to clean and meet sanitation standards. Proab stainless steel clamps and stainless steel fittings are made from upgraded food grade stainless steel. Our fittings ensure durability, safety, and resistance to bacterial buildup in food contact environments.

Egg Baling Machine

Power Drive Control Components & Conveying and positioning components

Filling and Sealing Machines

Fluid pipeline

Contact Profab to boost your project!

Food Industry Manufacturing Capabilities

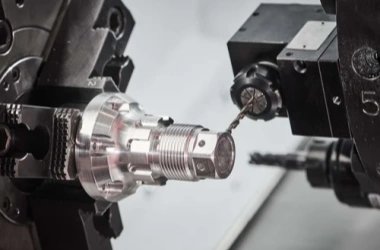

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Food Industry

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Food Experts Choose Profab

With more than two decades of experience in stainless steel fabrication, Proab offers solutions that help food manufacturers reduce the risk of contamination and extend the life of their equipment.

Precision Manufacturing for Food-Grade Safety

Proab specializes in the production of precision engineered stainless steel components for the food industry. These components meet strict hygiene and safety standards. With advanced CNC machining, hygienic welding and polishing finishing techniques. Each component we manufacture is easy to clean and highly resistant to corrosion. We understand the critical importance of food safety. Each product is designed to minimize the risk of contamination.

Stainless Steel Parts For Food Industry

We offer full customization and process traceability. From raw material selection to finished product sampling, every step of the process follows an ISO-based quality control system. Our components help food equipment manufacturers reduce downtime and increase sanitation efficiency. Proab Machine is your trusted partner in building cleaner, safer, and more efficient food production systems.

FAQ

What surface finish is best for food processing equipment?

Profab uses mirror polishing or electrolytic polishing of food contact areas to minimize bacterial growth and facilitate cleaning.

What surface roughness (Ra) standards can your products achieve?

Profab offers different surface finishes based on application requirements. Standard food-grade components typically feature a #4 brushed finish with a surface roughness of approximately 32 Ra. For applications requiring extremely high hygienic standards, we offer electropolishing, achieving a mirror-like surface finish with Ra < 15–20, effectively eliminating microscopic crevices where bacteria can accumulate.

Are the welds treated to meet hygienic standards?

We use full-penetration TIG welding. All welds on food-contact surfaces are manually ground and polished flush with the base material, ensuring there are no hidden cracks, pits, or crevices that could harbor contaminants.

Which material do you recommend for high-salt or high-acid environments?

We recommend using 316L stainless steel. The added molybdenum content significantly enhances resistance to pitting corrosion, helping prevent rust-through and premature failure after 1–2 years of service.

What level of high-pressure washdown can your components withstand?

Our components are specifically designed for heavy washdown environments, maintaining reliable sealing performance under high-temperature, high-pressure cleaning conditions.