Automotive

Source Custom Parts For Automotive Machinery

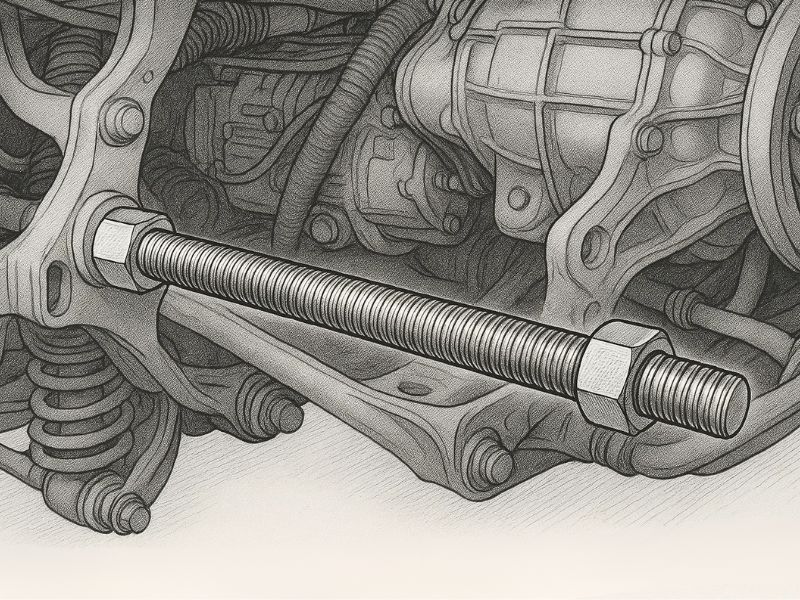

All components are made of corrosion- and high-temperature-resistant 304, 316 or 17-4PH stainless steel. Meet the automotive industry’s stringent requirements for fatigue strength, torque tolerance and surface accuracy.

The Aftermarket Tuning Market

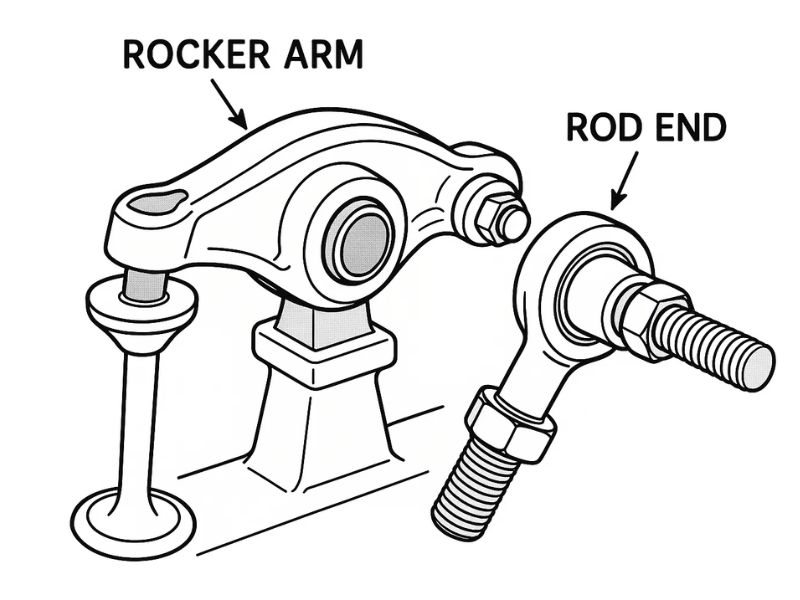

CNC precision machining for OEM and aftermarket retrofits

Advantages: Performance modifications and structural upgrades, decorative and visual modifications, repair and replacement parts support

Contact Profab to boost your project!

Automotive Machinery Manufacturing Capabilities

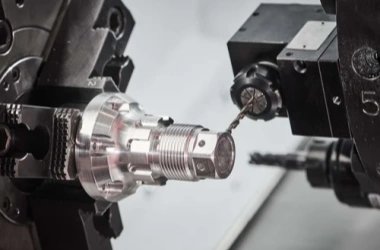

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Automotive

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Automotive Experts Choose Profab

Profab supports rapid prototyping based on drawings or samples. The products are used in a wide range of systems in the automotive industry. From standard parts to shaped parts, Profab meets the needs of customers at different levels, such as OEM&ODM and aftermarket. Rapid delivery and flexible ordering of small quantities allow for flexible response to customer needs and shorter development cycles.

Professional Surface Treatment Process

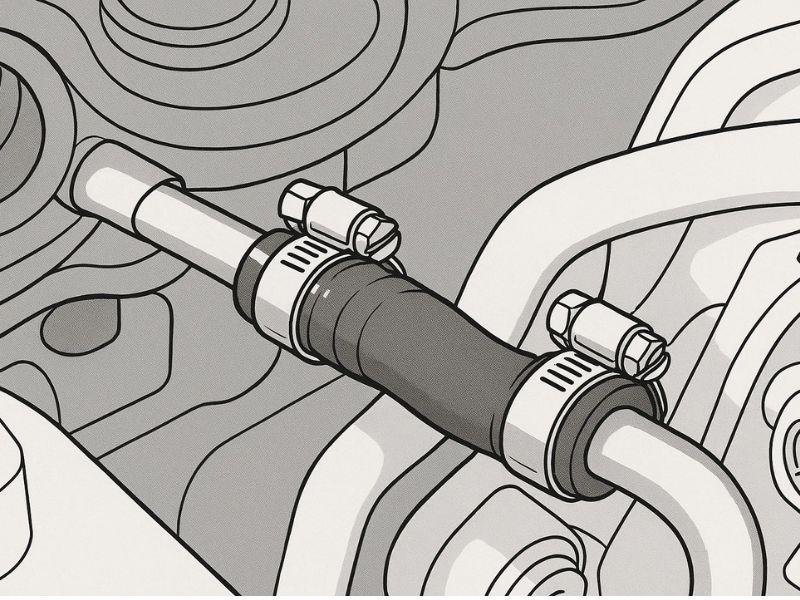

Support various surface treatment processes such as polishing, electrolysis, sandblasting, oxidization, passivation, blackening, etc. Enhance the durability and appearance quality of the products to meet the high requirements of the tuning market for visual and texture.

Strictly Selected Stainless Steel

Profab adopts 304, 316, 17-4PH, and other high-grade stainless steel raw materials. All parts have excellent corrosion resistance and mechanical strength to meet the needs of automotive systems in complex environments such as high temperatures, high pressures and strong vibrations.

FAQ...

Do your stainless steel parts meet the assembly precision requirements of the automotive industry?

Profab Machine is equipped with high-precision CNC machining centers. We control the regular tolerance to ±0.01mm to meet the stringent assembly standards.

Are stainless steel fittings suitable for high temperature environments in the engine compartment?

Yes. Pofab uses stainless steel materials such as 304, 316 or 17-4PH. All upgraded material has excellent heat and corrosion resistance.

Will stainless steel components rust when exposed to road salt during winter?

304 stainless steel resists most forms of road salt corrosion under normal conditions. For vehicles operated in coastal or heavy snow regions, we recommend 316L stainless steel, which offers superior resistance to chloride-induced corrosion.

What wall thickness options do you offer, and can weight be reduced without compromising strength?

We offer multiple wall thickness options (such as 16-gauge / 1.5 mm). By using high-grade 304 or 316L stainless steel, thinner wall sections can be specified while maintaining higher strength.