Aerospace

Source Custom Parts For Aerospace Industry

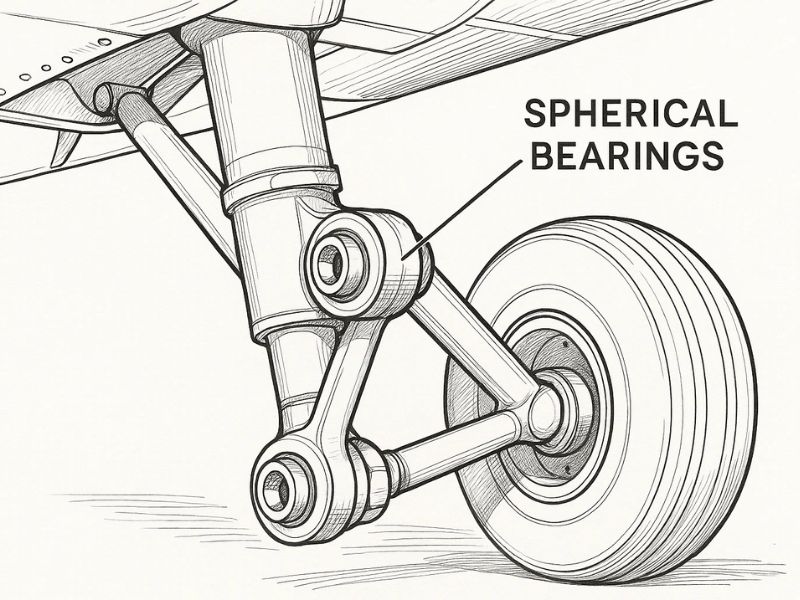

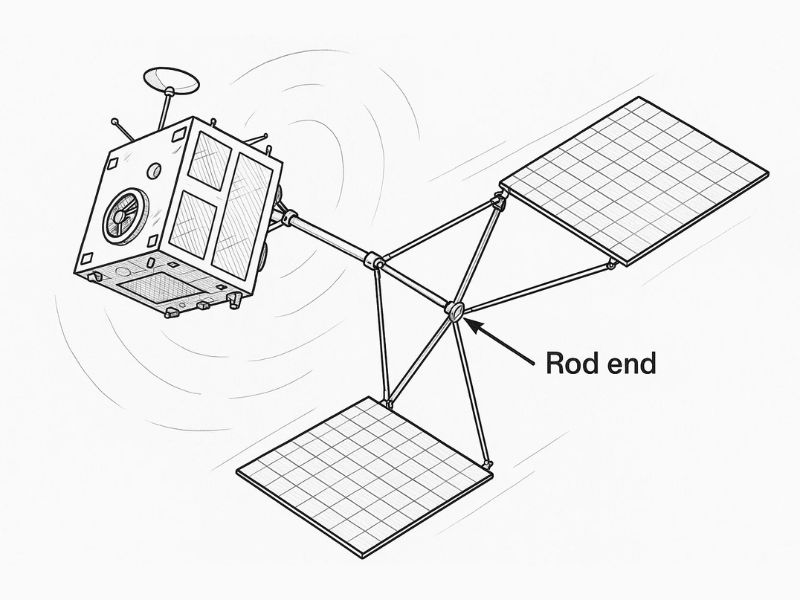

The aerospace industry demands the highest standards of performance, reliability, and quality from its components, and Profab provides aerospace-grade stainless steel precision components for a wide range of critical applications such as flight structures, control systems, propulsion systems, and ground test equipment. All products can be customized according to drawings, supporting high-precision machining, small-lot, multi-variety and high-reliability verification.

Contact Profab to boost your project!

Aerospace Industry Manufacturing Capabilities

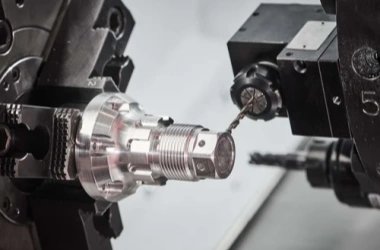

CNC Turning

Specialized in high-speed rotary and multi-face complex contouring.

Sheet Metal Fabrication

Integrated laser cutting, bending, punching, wire cutting and welding capabilities

Key Advantages of Stainless Steel Parts in Aerospace Industry

Corrosion Resistance

Easy Maintenance

High Hardness

High Temperature Resistance

Chemical Resistance

Recyclability

Why Aerospace Experts Choose Profab

Profab has a complete production system from raw material procurement, CNC machining, welding and assembly to surface treatment and precision testing. We specialize in serving the aerospace, automotive, machinery, and agricultural industries that demand the highest levels of performance and reliability.

Profab Advanced Equipment

Profab has a complete in-house machining process. Everything from cutting, milling, welding to surface treatment can be done in-house. This reduces outsourcing costs and ensures stable delivery. For small quantities or non-standard products, Profab can also flexibly arrange rapid prototyping and manual debugging, taking into account both efficiency and customization needs.

Profab Strict Testing Standards

Profab is equipped with a professional testing laboratory with high precision equipment such as CMM, hardness tester, spectrum analyzer and so on. We carry out multi-dimensional testing for each batch of products, such as dimensional accuracy, material composition, mechanical properties and so on.

FAQ

Which materials are suitable for high temperature and high pressure aerospace parts?

High strength and heat resistant stainless steels such as 17-4PH, Inconel, and Titanium alloys are recommended and have been widely used in engine and propulsion system components.