- By Profab /

- February 12, 2026

The decision to switch from conventional greased rod ends to self-lubricating alternatives in hydraulic systems addresses specific operational realities that grease-lubricated components cannot adequately solve. Over the past two decades working with hydraulic equipment across industrial, agricultural, and marine applications, the pattern is clear: self-lubricating rod ends solve problems where access, contamination, or duty cycle makes traditional lubrication impractical.

This article examines when self-lubricating rod ends deliver measurable value, where they fail, and what actual operating conditions should drive your selection process.

Table of Contents

Understanding Self-Lubricating Rod End Technology

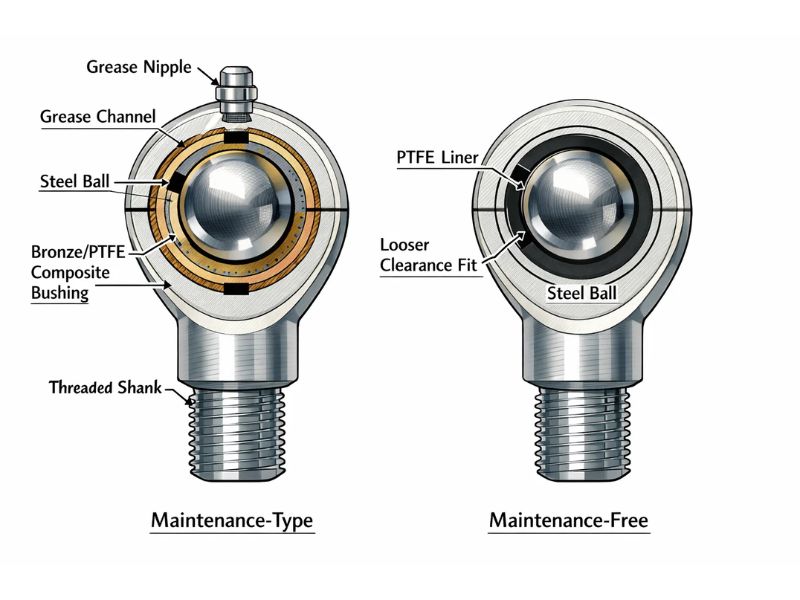

A self-lubricating rod end incorporates a PTFE (polytetrafluoroethylene) or PTFE composite liner bonded to the inner race. During operation, PTFE molecules transfer to the ball surface, creating a lubricant film. This is a wear mechanism—the liner sacrifices material to maintain lubrication. The liner does not regenerate; it has a finite service life determined by material thickness and operating conditions.

The construction differs fundamentally from greased bearings. Self-lubricating designs eliminate grease fittings, achieve tighter radial clearances, and employ different materials for both the race and ball. These design choices create specific performance characteristics and operational limits.

Wear Limits and Replacement Criteria

Replace when radial play exceeds 0.004 inches (0.1mm) or when visible liner degradation occurs. Service life depends on PV loading, contamination exposure, and misalignment severity.

When Maintenance-Free Rod Ends Actually Make Sense

Remote or Difficult-Access Locations

Hydraulic cylinders mounted in forestry equipment booms, agricultural spray arms extending 30 meters, or subsea actuators represent scenarios where physical access for relubrication becomes prohibitively expensive. A maintenance cycle requiring boom retraction, platform deployment, or service vessel mobilization can cost more than the component itself.

In these applications, maintenance-free rod ends eliminate scheduled lubrication. The economic threshold occurs when access cost exceeds 3-5 times the component cost. Below that ratio, standard greased bearings with extended service intervals typically prove more economical.

Contaminated Operating Environments

Contamination represents a primary failure mode in hydraulic equipment. Grease attracts and retains particulates. In dusty environments—grain handling, mining, cement production—grease films become abrasive paste within hours of application.

PTFE-lined bearings exhibit tighter radial clearances than greased equivalents, which provides some resistance to large particle ingress. However, PTFE is a soft material. Hard silica dust and fine abrasives can embed into the liner surface, acting as a lapping compound that accelerates wear. The tight fit alone does not prevent contamination damage.

Protection Requirements: External dust boots or shields are essential for high-grit environments. The liner’s dry surface does not attract contamination like grease, but it cannot self-clean once particles are embedded. Field data from grain elevator installations show 4-6 times longer service life compared to greased equivalents when proper sealing is implemented.

Marine applications present a different contamination profile. Salt spray corrodes grease fittings and degrades conventional lubricants. Stainless steel rod ends with PTFE liners eliminate both the corrosion pathway and the grease degradation mechanism.

High-Frequency Cycling Applications

Hydraulic systems cycling at 20,000+ cycles per day create lubrication challenges. Grease migration and breakdown occur rapidly. Relubrication intervals shrink to weeks or days. Labor cost for frequent service exceeds the component cost difference within months.

Packaging machinery, automated material handling, and repetitive manufacturing processes fall into this category. The operational profile—short stroke, high frequency, consistent load—matches the PTFE liner’s performance envelope. Contamination from process materials further penalizes greased bearings.

🔧 Critical Application Thresholds for Self-Lubricating Rod Ends

- Duty cycle exceeds 16 hours daily with minimal downtime windows

- Maintenance access requires equipment shutdown or special procedures

- Environment includes abrasive dust, chemical exposure, or saltwater

- Mean time between failures (MTBF) requirement exceeds 5,000 hours

Meeting these conditions typically justifies the component cost premium within 18-36 months of operation

Performance Characteristics That Matter

Load Capacity Limitations

PTFE composites exhibit lower compressive strength than metal-on-metal bearing surfaces. Load capacity varies significantly by liner construction:

- Basic PTFE thick-wall liners: 25,000-40,000 psi static load rating

- High-strength PTFE fabric liners (Nomex/Teflon weaves): Up to 80,000 psi static load rating

- Hardened steel-on-steel bearings: 90,000+ psi

Liner selection must match the application load profile. Undersizing based on thread diameter rather than bearing stress is a common specification error.

Shock loads accelerate liner wear regardless of static capacity. PTFE performs best under steady unidirectional loads. Reversing loads, particularly with magnitude variation exceeding 50%, cause premature liner degradation. Agricultural implement linkages with bidirectional loading require careful liner material selection or may necessitate metal-on-metal designs.

Temperature Operating Range

PTFE-based liners function from -40°F to approximately 400°F (-40°C to 200°C). However, liner performance is often limited by the bonding agent securing the liner to the race. Most standard bonding resins soften or degrade above 300°F (150°C). Applications requiring sustained operation above 300°F need specialized high-temperature bonding systems.

Beyond 400°F, the PTFE polymer matrix itself begins thermal degradation. Specialized high-temperature liners using modified PTFE or thermoplastic composites extend this to 450-500°F but cost significantly more.

Applications near hot exhaust manifolds, furnace mechanisms, or molten metal handling require careful thermal analysis. Heat soak from adjacent components often exceeds ambient ratings. Thermal barriers or component relocation may cost less than exotic liner materials and bonding systems.

Oscillation Speed Constraints

Self-lubricating rod ends operate effectively at oscillation speeds below 50 cycles per minute with angular displacement under 15 degrees. Higher speeds or larger angles generate frictional heat that exceeds the liner’s capacity for heat dissipation.

The PV factor (pressure × velocity) determines liner life. Most PTFE composites specify maximum PV of 10,000-15,000 psi·ft/min. Exceeding this threshold causes accelerated wear regardless of other operating conditions.

Material Selection for Hydraulic Applications

Stainless Steel Construction Benefits

Corrosion resistance represents the primary driver for stainless steel rod end selection. Grade 304 stainless provides adequate corrosion protection for indoor industrial environments and mild outdoor exposure. Marine applications, chemical processing, or saltwater exposure require 316 or 316L stainless steel. When sourcing components for demanding applications, working with an experienced maintenance-free rod ends supplier ensures proper material selection and quality verification.

The material cost differential—typically 40-60% premium for stainless versus carbon steel—must be justified by corrosion prevention over the component life. Surface treatment of carbon steel (zinc plating, black oxide) provides interim protection but requires periodic inspection and renewal.

Precipitation-hardening stainless alloys (17-4 PH) combine corrosion resistance with high strength. These materials suit high-load marine applications where both properties are essential. Material cost runs 2-3 times standard 304 stainless.

PTFE Liner Variations

Basic PTFE fabric liners serve general industrial applications with moderate loads and clean environments. Glass fiber reinforcement improves compressive strength by 40-60%, enabling higher load capacity. Bronze mesh backing further increases load rating but reduces the maximum operating temperature.

Advanced formulations incorporate solid lubricants (molybdenum disulfide, graphite) to extend life under higher PV loading. These specialized liners cost 50-100% more than standard PTFE. Application testing determines whether the performance gain justifies the cost.

Spherical Bearing Integration

Hydraulic cylinder rod end joints must accommodate misalignment from mounting flex, thermal expansion, and structural deflection. Spherical rod end bearings allow angular displacement typically 7-15 degrees depending on design.

Ball Surface Requirements: For PTFE transfer film formation to function properly, the mating ball surface must achieve Ra 0.2 μm (8 μin) or better. Rougher surfaces prevent uniform film development and accelerate liner wear. The ball material must be hardened to minimum 58 HRC to resist embedment of abrasive particles that would damage the PTFE liner.

The spherical geometry combined with PTFE lining creates a self-lubricating articulating joint. This capability proves essential in mobile equipment where cylinder mounting points move relative to each other during operation. Agricultural tillage implements, construction equipment, and truck suspensions depend on this misalignment capacity.

Where Self-Lubricating Rod Ends Fail

Spherical Bearing Integration

Undersized rod ends represent a common failure mode. Specification based solely on thread size rather than actual bearing load causes premature failure. The PTFE liner requires proper load distribution across the spherical surface.

Point loading from misalignment beyond the design angle crushes the liner material. This failure mode appears as visible deformation and increased play. Once liner compression occurs, replacement becomes necessary. Preventive measures include proper sizing and alignment verification during installation.

Edge Loading from Excessive Misalignment

Critical Failure Mode: If the rod end reaches its mechanical travel limit and the housing contacts the shank or mounting surface, the entire load concentrates at the edge of the liner. This edge loading instantly crushes the PTFE material, creating permanent damage.

Most spherical rod ends allow 7-15 degrees of angular displacement. Exceeding this angle—even momentarily under shock load—causes catastrophic liner failure. Applications with large deflections or mounting flex must account for maximum misalignment in the worst-case scenario, not nominal conditions.

Design Verification: Calculate maximum angular displacement including thermal expansion, structural deflection, and dynamic loading. Ensure the selected rod end’s angular capacity exceeds this maximum by a safety factor of 1.5-2.0.

Improper Installation Torque

PTFE-lined bearings require specific installation torque. Over-tightening compresses the liner, reducing its thickness and compromising the self-lubricating action. Under-tightening allows movement that wears the liner prematurely.

Manufacturer specifications typically provide a torque range, not a single value. Installation procedures should include calibrated torque wrenches and verification of proper torque application. Thread locking compounds must be compatible with stainless steel to prevent galling.

Grease Contamination

Adding grease to a self-lubricating rod end causes premature failure through two mechanisms. First, grease creates a barrier between the liner and ball surface, preventing PTFE transfer film formation. Second, and more critically, grease acts as a suspension medium for abrasive particles. Any contamination in the grease is held against the soft PTFE liner, creating a lapping compound effect that rapidly grinds away the liner material.

This failure mode appears when maintenance personnel attempt to “improve” performance by greasing components not designed for external lubrication. Once the liner surface is abraded away without the PTFE transfer mechanism functioning, friction increases dramatically and bearing failure accelerates.

Clear marking and documentation help prevent this error. Some manufacturers add permanent labels warning against grease application.

Theoretical math is just the foundation; bench testing is required for validation. Manufacturers use hydraulic systems to simulate years of impact and fatigue in a controlled environment. Only parts that pass static, dynamic, and impact tests should proceed to field trials.

Field monitoring with strain gauges and vibration analysis is becoming standard. One study found that actual peak loads were 32% higher than initial design assumptions. This data allows manufacturers to upsize components or optimize hydraulic buffering before a failure occurs. Vibration analysis can even predict a failure 2-3 months in advance.

Industry-Specific Applications

Industrial Hydraulic Systems

General factory floor applications present diverse requirements. Clean, temperature-controlled environments favor greased bearings for their higher load capacity and lower cost. Outdoor installations, high-cycle equipment, and contaminated processes justify maintenance-free designs.

The decision criterion should focus on actual operating conditions rather than assumed benefits. A proper specification includes environment description, duty cycle, load profile, and maintenance access constraints.

Agricultural Machinery

Implement linkages, spray boom pivots, and tillage equipment subject rod ends to high contamination loads combined with outdoor exposure. Maintenance-free rod ends reduce service requirements during busy planting and harvest periods when downtime costs peak.

However, shock loads from field conditions exceed the capacity of standard PTFE liners. Hardened balls and reinforced liner constructions address this requirement. Material selection should account for both contamination resistance and shock load capacity.

Material Handling Systems

Conveyor mechanisms, automated guided vehicles, and sortation equipment cycle continuously through defined motions. The repetitive nature creates ideal conditions for maintenance-free designs. Scheduled lubrication becomes impractical when systems operate 20+ hours daily.

Environmental concerns in food processing and pharmaceutical facilities prohibit conventional greases near product contact areas. PTFE-lined stainless steel rod ends meet both the operational requirement and regulatory constraints.

Marine Applications

Saltwater exposure accelerates corrosion of threaded fasteners, bearing surfaces, and mounting hardware. 316 stainless steel construction combined with PTFE liners addresses both corrosion and lubrication requirements.

Deck machinery, winch systems, and steering linkages benefit from elimination of grease fittings that corrode and allow water intrusion. The maintenance burden reduction proves particularly valuable on offshore platforms where service requires specialized personnel.

Making the Right Selection Decision

The choice between maintenance-free and conventional rod ends should follow from analysis of actual operating conditions. Consider these decision factors:

Access and Labor Cost: If service access requires more than 30 minutes of preparation or equipment repositioning, maintenance-free designs typically provide value.

Operating Environment: Contamination from dust, moisture, or corrosive elements favors PTFE-lined bearings. Clean indoor environments do not justify the cost premium.

Load Profile: Steady unidirectional loads suit maintenance-free designs. High shock loads, frequent reversals, or variable loading favor metal-on-metal bearings.

Duty Cycle: Continuous operation or high-frequency cycling makes scheduled lubrication impractical. Intermittent operation with accessible mounting permits conventional designs.

Service Life Requirements: Applications requiring 5+ years of operation without replacement need maintenance-free designs. Short service life applications (under 2 years) derive less benefit from the extended capability.

The decision matrix should weight these factors according to the specific application rather than applying generic assumptions about superiority.

Conclusion

Maintenance-free rod ends solve specific problems in hydraulic systems. They do not represent universal improvements over greased bearings. The technology excels in contaminated environments, remote locations, and high-duty-cycle applications where scheduled lubrication proves impractical.

Proper application requires understanding both the capabilities and limitations. Load capacity, temperature range, and oscillation speed all impose constraints that must be respected in the design process. Material selection, proper installation, and appropriate environmental protection ensure the components deliver their designed service life.

PROFAB MACHINE specializes in precision-engineered stainless steel components for demanding hydraulic applications. With two decades of experience in custom fabrication and materials selection, Profab supports OEMs and maintenance operations in identifying appropriate solutions for specific operating conditions and performance requirements.

Send Inquiry Now

Related Resource

Different Types of Rod Ends