You can check stainless steel welds in many ways. First, look at the weld to see if there are any problems on the surface. If you need to find deeper problems, use special tests like ultrasonic or eddy current testing. These tests help you find cracks and other hidden issues. Good welds keep your equipment safe and working right.

Common methods include:

- Visual inspection

- Liquid penetrant testing

- Ultrasonic testing

- Eddy current testing

Table of Contents

Testing Methods for Stainless Steel Welds

1.Visual Inspection

Visual inspection is the first step in checking stainless steel welds. You can spot many problems just by looking closely. This method is quick and does not need special tools, but you can use magnifiers or gauges for a better view. Good lighting is important—500 lux for general checks and 1000 lux for detailed work.

Here are the main steps you should follow:

Before Welding:

Check the materials for quality and cleanliness.

Make sure the joint fits well and the equipment settings are correct.

During Welding:

Watch the weld bead for cracks or poor penetration.

Inspect each layer, especially the first one, for problems like undercut or trapped slag.

After Welding:

Clean the weld so you can see the surface clearly.

Look for cracks, holes, or uneven areas.

You can find defects like cracks, porosity, undercut, and surface slag. International standards, such as AWS D1.6 and ISO 9606-1, require visual inspection by trained people. These standards focus on finding surface problems that could weaken the weld. Visual inspection is a must before you use more advanced tests.

Tip: Use a magnifier and good lighting to spot small cracks or pits that are hard to see with the naked eye.

2.Surface Testing

Surface testing helps you find defects that may not be visible right away. The most common methods are dye penetrant testing (PT), magnetic particle inspection (MT), and eddy current testing.

Dye Penetrant Testing (PT):

You apply a colored or fluorescent liquid to the weld. The liquid seeps into cracks or pores. After wiping off the extra liquid, you spray on a developer. Cracks show up as colored lines. PT works well for stainless steel welds and is easy to use.

Magnetic Particle Testing (MT):

This method uses a magnetic field and powder to find cracks. The powder gathers at defects, making them visible. MT only works on some types of stainless steel because not all grades are magnetic.

Eddy Current Testing:

Eddy current probes use electromagnetic fields to find surface and near-surface defects. Flexible probes can scan welds of different shapes and record data for later review. This method works well for stainless steel welds because the metal is usually non-magnetic.

Surface testing helps you find cracks, notches, and other surface-breaking defects. You can use these methods on weld crowns, toes, and heat-affected zones.

3.Non-Destructive Testing

Non-destructive testing (NDT) lets you check inside stainless steel welds without damaging them. You can use several NDT methods, each with its own strengths.

NDT Method | What It Finds | Notes |

Ultrasonic Testing | Internal cracks, voids, and inclusions | Good for thick welds; needs skilled users |

Radiographic Testing | Porosity, inclusions, cracks, and voids | Makes a film record; needs both sides open |

Eddy Current Testing | Surface and near-surface cracks | Fast and records data |

Magnetic Particle | Surface cracks (ferromagnetic only) | Not for most stainless steel welds |

Penetrant Testing | Small surface cracks and pores | Needs smooth, clean surface |

Ultrasonic testing uses sound waves to find flaws deep inside the weld. It works well for thick welds and gives quick results. However, stainless steel can make this test harder because it scatters sound. New probe designs and phased array ultrasonic testing (PAUT) help solve these problems. Radiographic testing uses X-rays or gamma rays to make images of the weld. It shows the size and shape of hidden defects but takes more time and costs more. Both methods need trained operators.

Note: Phased array ultrasonic testing and AI tools now make flaw detection faster and more accurate.

4.Destructive Testing

Destructive testing checks the strength and toughness of stainless steel welds by breaking or deforming samples. You use this when you need to know the weld’s true mechanical properties.

Tensile Testing:

You pull the weld until it breaks. This test shows how much force the weld can take and how much it stretches.

Bend Testing:

You bend the weld over a set radius. If it cracks or breaks, the weld may not be strong enough.

Hardness Testing:

You press a hard tip into the weld and measure how deep it goes. This shows how tough or brittle the weld is.

Macro Etch Testing:

You cut and polish a cross-section of the weld, then use acid to reveal the weld’s structure. This helps you see how well the weld fused and if there are hidden flaws.

Destructive tests give you clear numbers for strength, ductility, and hardness. They help you find weak spots that other tests might miss.

5.Chemical and Corrosion Tests

Stainless steel welds must resist rust and corrosion, especially in harsh environments. Chemical and corrosion tests check how well the weld stands up to these threats.

ASTM A923:

Checks for harmful phases in duplex stainless steels.

ASTM A262:

Tests for intergranular corrosion, which happens when chromium is lost at grain boundaries.

ASTM G48:

Measures resistance to pitting and crevice corrosion, especially in salty or wet places.

ASTM G28:

Looks at corrosion resistance in acidic conditions.

You can also use electrochemical tests, like the critical pitting temperature (CPT) test. This test finds the lowest temperature where pitting starts. It helps you compare the corrosion resistance of different welds. These tests are important in industries like food processing and chemical plants, where welds face tough cleaning chemicals or acids.

Tip: Always choose the right test for your weld type and the environment where it will be used.

Interpreting Results and Weld Quality

Common Defects

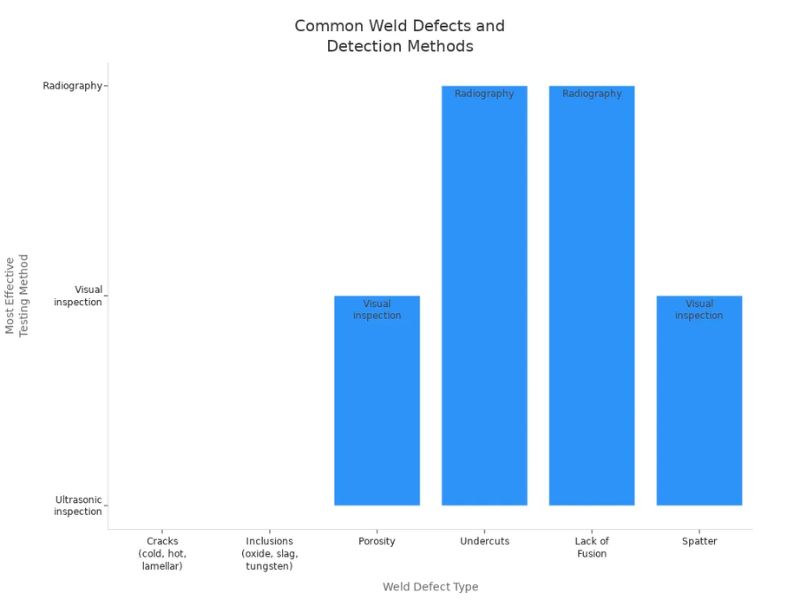

Stainless steel welds can have different problems. Each problem happens for a reason. You need special tests to find each one. The table below lists the main problems, what causes them, and the best way to find them.

| Weld Defect | Description / Causes | Most Effective Testing Methods |

|---|---|---|

| Cracks (cold, hot, lamellar) | Hydrogen, thermal stress, low ductility, inclusions. Cold cracks form below 200°C; hot cracks during solidification. | Ultrasonic, Radiography, Liquid penetrant (surface) |

| Inclusions | Oxides, slag, or tungsten trapped by poor shielding or electrode issues. | Ultrasonic, Magnetic particle, Radiography |

| Porosity | Gas trapped by contamination or wrong settings. | Visual, Ultrasonic, Eddy current |

| Undercuts | High current, long arc, poor joint design. | Radiography |

| Lack of Fusion | Not enough heat or poor technique. | Radiography, Ultrasonic |

| Spatter | Arc welding issues, bad filler, or shielding gas. | Visual |

Factors Affecting Quality

Many things can change how good your weld is. Watch out for these:

- The mix of metals changes how easy it is to weld. Carbon, chromium, and nickel change strength and rust resistance.

- Some stainless steels, like austenitic, keep heat. This can bend the weld or make it rust faster.

- The welding method you pick controls heat and cooling. This helps stop cracks and rust.

- Steps like preheating, keeping the right temperature, and heating after welding matter for some types.

- The right filler and settings make the weld strong and stop rust.

- Each type of stainless steel is different. You may need to change your steps for austenitic, ferritic, or martensitic steels.

Fixing

If you find a problem, you need a plan to fix it. Do these things:

- Check welds often so you find problems early.

- Write down all test results so you can look back later.

- Use trained inspectors for every check.

- Try new tools like electronic radiography for better results.

- Store and move materials carefully so they do not get dirty or damaged.

- Watch every step of making the weld to catch problems fast.

- Always follow rules like ISO and ASTM.

You should use both non-destructive and destructive tests to check weld quality. Clean tools, control heat, and match filler metals for best results. If you find defects or feel unsure, ask a welding expert for help.

Good welds keep your projects safe and strong.Profab offers industry-leading precision welding technology. Every weld is monitored by automated welding parameters and visually inspected by hand, giving your equipment unrivaled structural safety and longevity at the source.

FAQ

What does a good stainless steel weld look like?

A good weld looks smooth and even. You should not see cracks, holes, or sharp edges. The color should match the base metal.

Can you test welds without special equipment?

Yes. You can use your eyes and a magnifier for basic checks. For deeper problems, you need special tools.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints