- By Profab /

- December 4, 2025

In daily road vehicles, carbon-steel and chromoly-steel heim joints are commonly used. These materials offer high strength and low cost, making them suitable for suspension and steering systems. But does this mean stainless steel heim joints have no place in the market? Not at all.

For off-road and modified vehicles, corrosion, sand, dust, and salt spray are constant threats. The inherent properties of stainless steel address these challenges perfectly. In particular, three-piece stainless steel heim joints with self-lubricating liners eliminate the frequent lubrication required by standard rod ends.

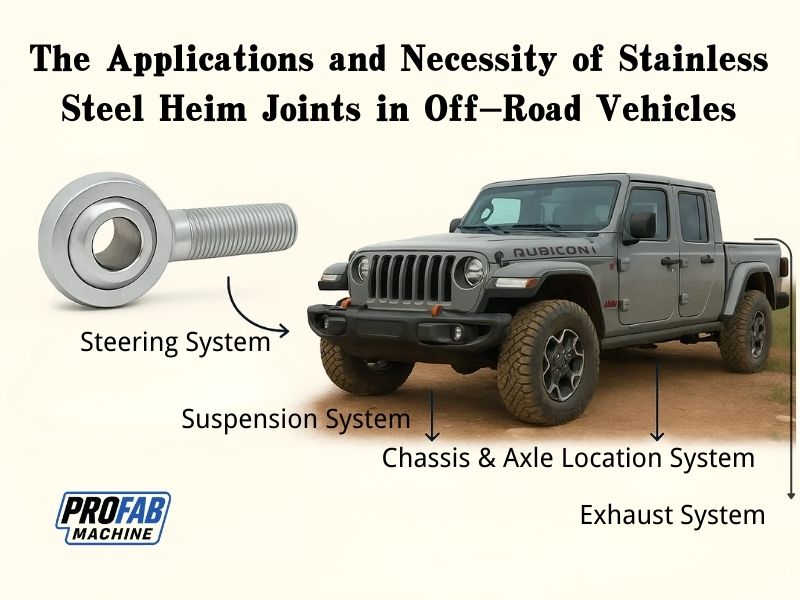

Below, Profab Machine will explain why stainless steel heim joints are necessary in off-road and modified vehicles, using real application scenarios as the foundation.

Table of Contents

Applications in Off-Road Vehicles / ATVs / UTVs / Sand Cars

Exhaust System

Carbon-steel heim joints easily seize, rust, and lose lubrication at high temperatures. Stainless steel heim joints ensure smooth operation, long life, and minimal maintenance.

1. Exhaust Valve Actuator Linkage

Heim joints are often used to connect the exhaust valve to the actuator. Carbon steel can rust and cause the valve to stick. Stainless steel heim joints avoid seizure caused by heat cycling, moisture, and corrosion while maintaining precise control of exhaust sound and flow.

2. Wastegate / Turbo Actuator Rod

The small linkage rod on a wastegate actuator relies on heim joints to maintain precise micro-movement. Stainless rod ends prevent rust-related boost instability.

3. Turbo Exhaust Actuator Rod

Stainless heim joints stabilize the actuator while resisting water, salt, and oil vapor corrosion.

Suspension System

Suspension components experience large articulation angles, heavy impacts, and high loads. Heim joints increase suspension adjustability and expand travel range. Stainless steel further prevents thread seizure caused by mud and water.

1. Control Arms / A-Arms

Heim joints are usually mounted at the ends of upper and lower control arms. They provide precise fine adjustment and enable greater off-road articulation.

2. Toe Links / Camber Links

They allow precise alignment without restricting suspension movement. Stainless steel heim joints extend lifespan in muddy, sandy environments.

3. Sway Bar End Links

Modified vehicles commonly use heim joints as end-link connectors. They reduce torsional deflection under lateral load and improve handling response. Stainless rod ends do not age quickly like rubber bushings.

4. Shock / Bump Stop Mounts

They provide rotational compensation. Stainless heim joints prevent rubber eyelets from tearing during off-road impact.

5. Suspension Limit Strap Hardware

These joints absorb extension impacts. Stainless heim joints help maintain long-travel suspension reliability.

Steering System

The steering system is a safety-critical assembly, requiring the highest reliability from rod ends.

1. Steering Link

Transfers steering input precisely from steering wheel to wheels. Stainless heim joints resist mud, water, and salt-spray contamination that often causes sticking. Material advantages ensure responsive steering even in rocky, muddy, or wet environments.

2. Drag Link

Lifted vehicles require adjustable drag links to correct steering geometry. Heim joints offer larger misalignment angles to accommodate lift kits. Stainless rod ends resist impact, corrosion, and reduce maintenance frequency.

Chassis & Axle Location System

These components maintain axle position and vehicle stability during high-speed driving and off-road impacts.

1. Track Bar / Panhard Bar

One of the most heavily loaded positions for rod ends. It stabilizes axle lateral location and absorbs side loads. Stainless steel heim joints prevent salt-induced seizure and maintain precise centering.

Control & Functional Linkages

1. Shifter Linkage

Heim joints provide smooth, precise shift movement. Stainless steel resists contamination from mud and sand.

2. Winch Fairlead Bracket Linkage

Stainless steel heim joints allow micro-adjustment of fairlead angle and prevent corrosion.

Why Stainless Steel Heim Joints Are Necessary

Stainless Steel vs. Carbon Steel

Corrosion Resistance

Carbon steel rod ends rust quickly when exposed to salt spray, moisture, heat, and mud. Once corrosion begins, rod ends seize, fail, and accelerate ball wear. Profab uses high-grade 304 and 316 stainless steel, ideal for high-heat and high-corrosion off-road environments.

Maintenance

Carbon-steel rod ends require frequent external lubrication—impractical in off-road conditions. Stainless steel rod ends provide smoother, longer-lasting movement with minimal maintenance.

Temperature & Exhaust Compatibility

Carbon steel lubricants evaporate near the hot exhaust system, accelerating seizure. Stainless steel remains stable under continuous high-temperature exposure.

Stainless Steel vs. Chromoly Steel

Corrosion Resistance

However, chromoly requires plating or coating for corrosion protection. These coatings wear quickly in off-road environments. Stainless steel needs no coating. Its corrosion resistance is inherent, making it ideal for harsh outdoor use.

Maintenance Frequency

Chromoly rod ends are designed for track conditions where maintenance is frequent. Off-road environments destroy coatings faster, requiring more upkeep. Stainless rod ends with self-lubricating liners are much better suited for low-maintenance scenarios.

Long-Term Smooth Movement

Chromoly has high strength, but rusts and wears faster in wet, muddy environments. Stainless steel maintains smooth motion without seizing.

Conclusion

Stainless steel heim joints have become a vital component in modern off-road vehicles—not only because they resist harsh outdoor environments, but because they ensure smooth operation across exhaust, steering, suspension, and chassis systems. Compared with carbon-steel and chromoly rod ends, stainless steel is far better suited to muddy, sandy, and corrosive off-road conditions.

Profab Machine uses upgraded stainless materials and strict quality control at every stage. Our stainless heim joints support full customization of size, thread type, surface finish, and packaging. Profab is committed to being the dependable partner that keeps your off-road vehicle performing at its best.

FAQ

Can stainless steel heim joints reduce noise or vibration?

Yes. Stainless heim joints with PTFE liner maintain smoother articulation for longer.

Are stainless steel heim joints worth the higher cost?

The initial cost of stainless steel heim joints is slightly higher. However, from a long-term perspective, their extended service life, low maintenance requirements, and superior corrosion resistance help prevent frequent upkeep and downtime.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints