- By Profab /

- November 12, 2025

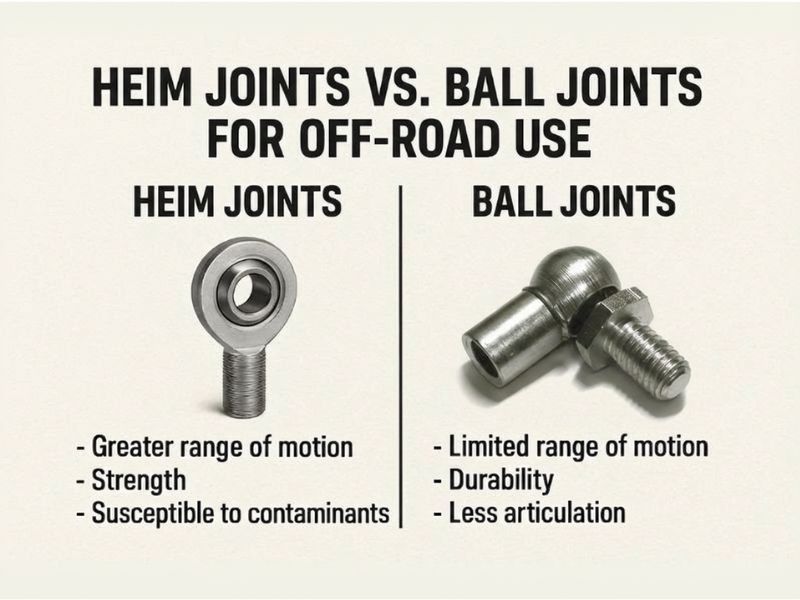

When you look for the best joint for off-road use, you want strength, durability, and the right fit for your build. In the heim joint vs ball joint debate, each type stands out for different reasons. Heim joints use a metal-to-metal design, which gives them good strength and allows for a high degree of misalignment. Ball joints usually last longer and need less attention, but they may not handle extreme angles as well. You should think about how much maintenance you want to do, the type of terrain you drive on, and the load your vehicle will carry.

Table of Contents

Heim Joint vs Ball Joint Strength

Heim Joint Strength

You might notice that heim joints stand out for their ability to handle high loads, especially when you need a wide range of movement. The metal-to-metal design gives you solid strength in many off-road setups. Heim joints allow for more misalignment, which helps when your suspension moves in extreme ways. You can use heim joints in places where you need flexibility and quick response.

Common failure points for heim joints include:

- Deformation at the base of the socket

- Breakage at the jam nut

- Problems from misalignment or using the wrong size

If you install heim joints correctly and check them often, you can avoid most problems. You should remember that heim joints do not have a protective boot, so dirt and water can get inside and cause wear.

Ball Joint Strength

Ball joints usually offer higher overall strength compared to heim joints. You get a sealed design that keeps out dust and water, which helps the joint last longer. Ball joints work well in heavy-duty trucks and off-road vehicles that need to carry a lot of weight. The design supports vertical and horizontal loads, so you get reliable performance on rough terrain.

Ball joints resist bending and breaking better than heim joints in most cases. You can trust ball joints to handle the stress from jumps, bumps, and uneven ground. The protective boot keeps the grease inside and blocks out harmful debris.

Heim Joint vs Ball Joint Durability

Heim Joint Durability

Heim joints give you strong performance in tough off-road conditions. You get a metal-to-metal design, which means the joint can handle dirt, mud, and water without breaking down quickly. If you choose a two-piece heim joint with a Teflon or Kevlar race, you get even better protection against wear. This design helps the joint keep its strength, even when you drive through mud or face harsh winter weather.

You need to keep heim joints clean and lubricated. If you do regular maintenance, you can expect a long service life. Many users report that their heim joints last for years, even after trips through mud and rough terrain. Some heim joints, when properly cared for, can last from 10,000 up to over 100,000 hours.

Ball Joint Durability

Ball joints use a sealed design, which keeps out water, mud, and dust. You get less wear because the grease stays inside and dirt stays out. Ball joints need less maintenance than heim joints. You do not have to clean or lubricate them as often.

Most ball joints in off-road trucks last between 31,000 and 62,000 miles. If you drive on bumpy roads or carry heavy loads, the joints may wear out faster. The sealed boot protects the joint from harsh conditions, so you get a longer lifespan with less work.

Heim Joint vs Ball Joint Applications

Heim Joint Uses

You often see heim joints in off-road vehicles where flexibility and strength matter most. These joints work well in places that need a wide range of movement. You can find heim joints in many parts of your vehicle:

- Tie rods

- Traction bars

- Sway bars

- 4-links

- Panhard bars

- Spoiler supports

- Steering links

Heim joints help you get better control and more articulation. You will notice their benefits in vehicles built for rock crawling, dune racing, or tough trails.

Ball Joint Uses

Ball joints play a key role in off-road vehicles. You will find them in suspension systems and steering mechanisms. Ball joints connect control arms to steering knuckles. This connection lets your wheels move in all directions. You need this movement to keep your tires on the ground when you drive over rocks, mud, or uneven trails. Ball joints help your vehicle handle rough terrain and keep you safe.

Choosing the Right Joint

When to Choose Heim Joints

You should pick heim joints if you want maximum articulation and control. These joints work best for custom builds, rock crawlers, and vehicles that need extreme movement. Heim joints let your suspension move freely, which helps on rough trails and rocky terrain. You need to clean and lubricate heim joints often. If you enjoy working on your vehicle and want top performance, heim joints fit your needs.

When to Choose Ball Joints

Ball joints suit you if you want durability and low maintenance. You find ball joints in most off-road trucks and daily drivers. The sealed design keeps out dirt and water, so you spend less time on upkeep. Ball joints last longer and handle heavy loads well. You should use bolt-in ball joints from trusted brands like Profab Machine for custom control arms. Make sure the knuckle side has a taper fit unless you build the knuckle from scratch. Always check the shear and tensile strength of the ball joint pin and the arm to match your setup.

Tips

If there is excessive wear and tear on the ball joints or if there is a strange noise, please take care to check the situation to ensure safe driving.

In conclusion, when outfitting your off-road vehicle, choosing between heim joints and ball joints comes down to matching the right joint to your specific driving demands. For precision steering and solid load-bearing you may lean toward ball joints. For rapid articulation, extreme angles, and modular replacement the heim joint often shines. What matters most is ensuring proper installation, suitable materials, and routine inspection to keep performance and safety at their peak.

Want both durability and precision for your suspension components? Trust Profab Machine to deliver top-quality rod ends and joints engineered for the toughest terrain.

FAQ

What is the main difference between heim joints and ball joints?

Heim joints give you more movement and flexibility. Ball joints offer better protection and last longer. You should choose based on your off-road needs.

Do heim joints need more maintenance than ball joints?

Yes. Heim joints need regular cleaning and lubrication. Ball joints have a sealed design, so you spend less time on upkeep.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints