Stainless Steel Wheel Spacer

Stainless Steel Wheel Spacer Manufacturer in China

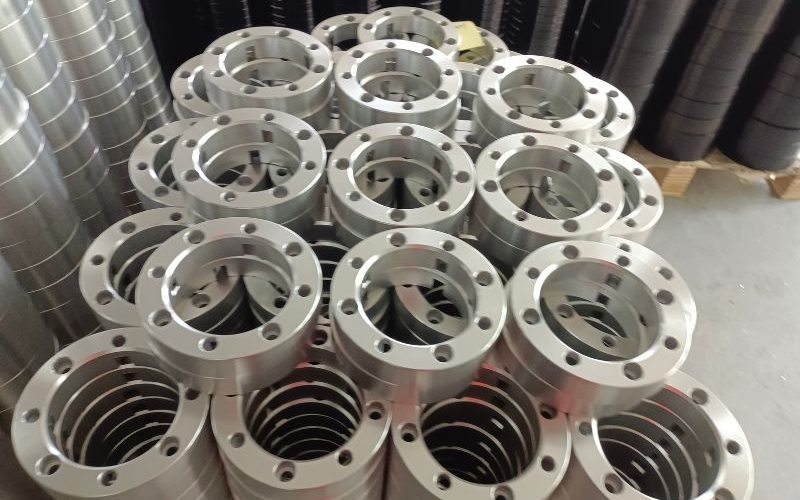

Stainless steel wheel spacers are precision-machined rings that mount between the wheel hub. It can increase the wheel offset while keeping the hub centered. Compared with aluminum or carbon steel spacers, stainless steel spacers offer superior strength, corrosion resistance, and long-term durability. They are ideal for demanding environments or heavy-duty wheels.

Stainless wheel Spacers allow installation of wider tires, larger brake calipers, or custom wheels without rubbing or interference. Profab wheel spacers are reliable under heavy load, rough terrain, and harsh conditions.

- Better clearance for wheels, tires, and brakes

- Heavy-duty and reliability for off-road / utv

- Longevity and low maintenance

- Safety and balanced performance

Custom SS Wheel Spacer Manufactured To Your Drawings

Profab supports custom stainless steel wheel spacers fully built to your drawings, specifications, and load requirements. Every wheel spacer is precision-machined from high-grade stainless steel to ensure exceptional strength, exact fitment, and long-term resistance to rust, salt, and harsh road conditions.

Our engineering team supports one-off prototypes, small batches, and full production runs. Our goal is to achieve the perfect wheel offset, brake clearance, and stance without compromising safety.

Application of Stainless Steel Wheel Spacer

Stainless steel wheel spacers are widely used in off-road and UTV vehicles, especially in suspension systems for radius rods, tie rods, and downlinks. They handle constant water, mud, and impact, ensuring the components do not seize or rust. In heavy-duty trucks and trailers, stainless steel provides the strength needed for high tensile forces and continuous heavy loads. Our wheel spacers are also ideal for marine and coastal use.

Why Choose PROFAB

Profab Machine provides a comprehensive product line, from standard to custom-fabricated solutions, ensuring seamless integration into critical applications across the Industrial, Automotive, Aerospace, Solar Energy, Medical, and Marine sectors. Our commitment to precision manufacturing and rigorous quality control guarantees a superior product that meets your exact specifications.

- 20 Years Of Professional Manufacturing Experience

- Comprehensive solutions, not just products

- Comprehensive Surface Treatments

- Stringent Quality Control and Traceability

- Immediate response, regardless of project size

FAQ

You May Also Ask

What does a wheel spacer do?

Its primary function is to increase the distance between the wheel and the wheel hub assembly.

What tolerance and surface finish can you achieve?

We support tight tolerances with optional polishing, passivation, and anti-seize surface treatments.