- By Profab /

- September 11, 2025

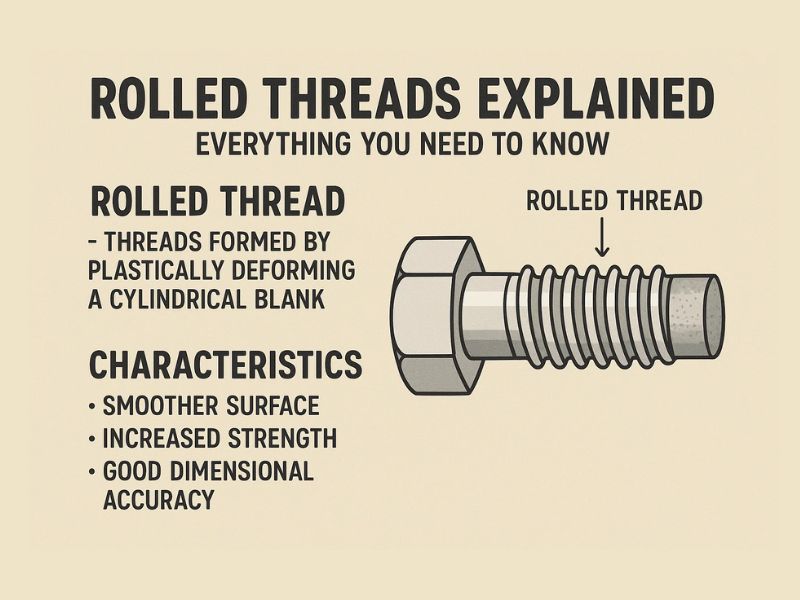

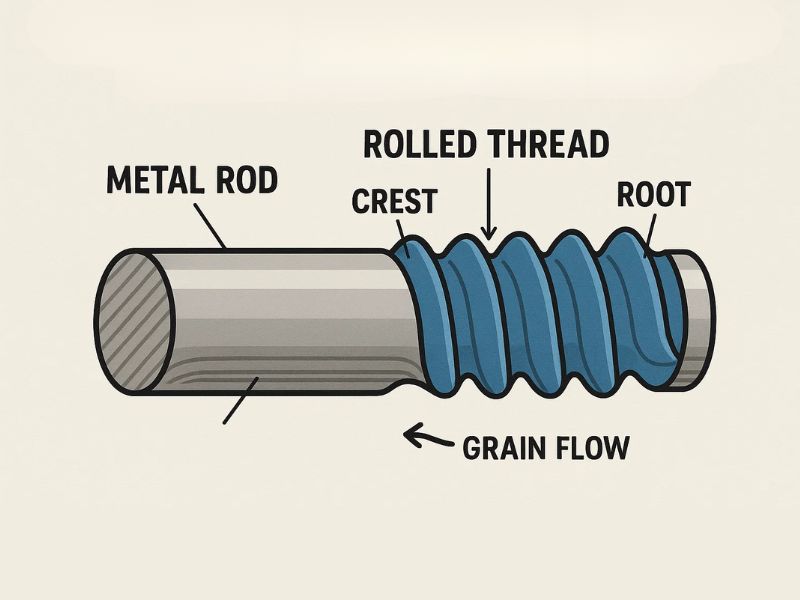

Rolled threads are made by pressing or rolling a hard die into a metal rod. This shapes the threads without cutting the metal. This way, the threads are stronger and more dependable. The metal grains move with the thread shape and do not break.

Rolled threads are stronger than cut threads. They keep the metal grains lined up. Using rolled threads can save time and money. This is true for big orders. The process is faster and makes less waste. Here’s everything you might want to know about roll threading.

Table of Contents

Rolled Threads Overview

What Are Rolled Threads

You create rolled threads by pressing a hardened die onto a metal rod. The die rolls along the rod and shapes the threads without cutting into the metal. This process keeps the metal grains flowing along the thread shape. You get threads that are stronger and smoother.

Industry standards help define rolled threads. Here are some of the main standards you may see:

- BS 2517: Definitions for Use in Mechanical Engineering

- BS 3643: ISO Metric Threads

- BS 4827: ISO Miniature Threads

- BS 4846: ISO Trapezoidal Threads

- BS 21: Pipe Threads for Tubes and Fittings

Tips

Why Choose Rolled Threads

You want your parts to last and perform well, and rolled threads help you reach that goal. The rolling process makes the threads stronger and more reliable than cut threads. Rolled threads have improved strength and surface integrity. Rolling creates compressive stresses that make the material stronger. These stresses also give the threads better fatigue resistance.

You will find rolled threads in many stainless steel components, such as rod ends, ball joints, and threaded rods. Profab uses advanced machines to make sure each thread meets strict standards.

Tips

Thread Rolling Process

How Thread Rolling Works

First, you pick the right material for your job. Then, you turn the material into long, straight bars. Next, a thread rolling machine shapes the threads onto each rod. After that, you make the rods straight and smooth out the surface. You cut the rods to the size you need. Each rod gets checked to make sure it is high quality.

This process makes threads that are very exact and repeatable. You get the same results every time, which is important for cars and airplanes. Profab uses modern machines and careful checks to make sure stainless steel parts are always reliable.

Tools and Machines

Special machines are needed to roll threads well. The most common types are:

- Planetary thread rolling machines: These keep the rod still while rollers make the threads.

- Rotary thread rolling machines: These work like planetary machines and are used for similar jobs.

- Infeed rolling machines: These use round dies for short threads and are good for making many at once.

- Thrufeed rolling machines: These make long threads in one go, so they are best for simple shapes.

These machines help you make good threads fast. They also make less waste because they shape the metal instead of cutting it.

Material Suitability

You can roll threads on many materials, but some work better. Steel alloys, stainless steel, titanium, brass, bronze, aluminum, and high-temperature alloys all work well. These materials are strong, bend without breaking, and resist rust, which is good for rolling. Stainless steel is great because it does not rust, so it is used for food, medical, and marine parts.

Rolled Threads Advantages

The rolling process increases the yield strength by about 41.2% and the hardness by about 39.4%. It provides higher yield strength, greater hardness, a smoother surface, and better wear resistance.

Strength and Durability

You want your threaded components to last under pressure. Rolled threads give you a big advantage in strength and durability. The rolling process compresses the metal grains, making the threads up to 20 percent stronger than cut threads. You get threads that resist stretching and breaking, even in tough environments. The cold working during rolling also makes the surface harder, so your parts stand up to repeated use.

Tips

Fatigue Resistance

Fatigue resistance matters when your parts face repeated stress. Rolled threads perform better than cut threads in lab tests. Here is what you can expect:

- Rolled threads have a much lower failure rate in destructive tests.

- The rolling process boosts tensile, shear, and fatigue strength.

- Aerospace components with rolled threads pass more lab tests than those with cut threads.

You can trust rolled threads for applications where safety and reliability are critical.

Speed and Cost

You save time and money with rolled threads. The rolling process is fast and efficient. You only need one pass to form the threads, while cutting usually takes ten passes. Here are some key points:

- Thread rolling works best when you produce 4,000 parts or more.

- You can roll threads up to ten times faster than you can cut them.

- Less material waste means lower costs per part.

This efficiency helps you meet tight deadlines and control your budget.

Surface Finish

Surface finish affects how your threads perform and look. Rolled threads have a smoother finish than cut threads. The rolling process removes unevenness and leaves a burnished surface. Compare the roughness below:

Thread Type | Surface Roughness (micro-inches Ra) |

Rolled | 32 or less |

Cut | Rarely less than 63 |

Rolled threads often achieve a finish between 8 and 24 micro-inches Ra. Cut threads usually measure between 64 and 125 micro-inches Ra. Smoother threads reduce friction and wear, which helps your parts last longer.

Applications of Rolled Threads

Best Materials

You need to pick materials that work well for rolled threads. Some metals are better because they are strong and tough. They also last longer and do not wear out as fast. Stainless steel is a top choice. It does not rust and works well in rough places. Other good materials are used for thread rolling, too. Here is a simple comparison:

Material | Advantages | Applications |

Carbide (Tungsten) | Very tough, wears down slowly, very exact | Used for heavy-duty fasteners, aerospace parts, special threads |

DC53 Steel | Tough, does not wear out quickly, easy to shape | Used for making lots of regular fasteners |

D55 Steel | Very hard, lasts long, does not chip easily | Used for exact threads and rough materials |

High-Speed Steel (HSS) | Not expensive, handles heat well, easy to find | Used for general dies in small or medium batches |

Profab uses stainless steel in many parts. It does not rust and stays strong in hard jobs.

Industry Uses

Rolled threads are used in many fields that need strong fasteners. These threads help parts last longer and work better when stressed.

Profab’s stainless steel parts are used in cars, boats, hospitals, and factories. You get better strength and a lower chance of breaking. This is great for jobs that need exact and rust-proof parts.

When Not to Use

Rolled threads are not right for every job. Sometimes, thread rolling is not the best choice. Rolling tools have a higher initial setup cost and take longer to set up than cutting tools. Rolling machines also have thread length and diameter limitations, so some parts may not fit. In addition, not all materials are suitable for rolled threads, as some may break or crack, which can damage tools or slow down work.

Rolled Threads vs Cut Threads

Process Differences

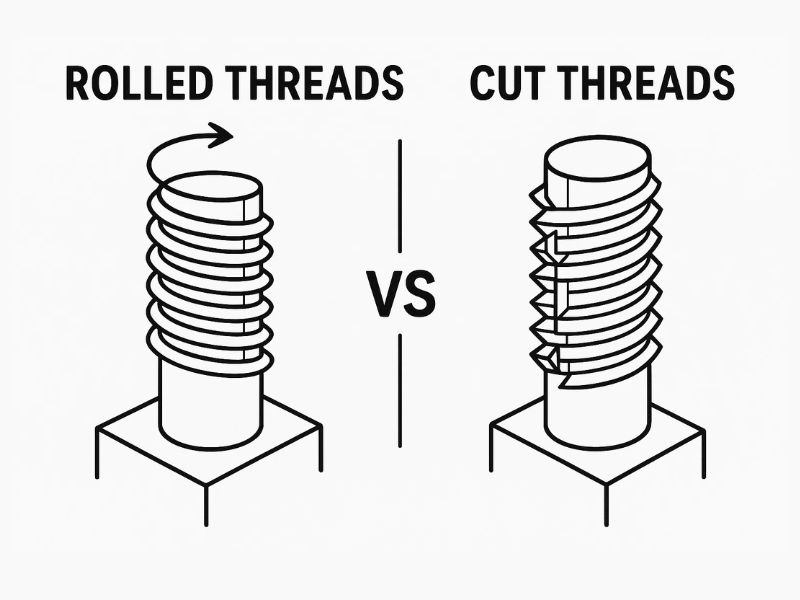

It is important to know how rolled threads and cut threads are made. The way you make threads changes how strong and smooth your parts are. Here is a simple comparison:

Feature | Rolled Threads | Cut Threads |

Method of Formation | Cold-forming process using hardened steel | Material removal using cutting tools |

Structural Impact | Does not interrupt structural composition | Leaves tool marks on the workpiece |

Precision | More precise due to no tool marks | More precise for creating threads of any diameter |

Installation Smoothness | Smooth installation due to thread formation process | May not be as smooth due to cutting process |

Damage Resistance | Significantly resistant to damage | Less resistant due to the nature of cutting |

Rolled threads are made by pressing metal into shape. No metal is taken away. This keeps the grain structure strong. Cut threads are made by carving out the thread with a tool. This can leave marks and change the metal’s structure.

Performance Comparison

You want threads that last when used a lot. Rolled threads perform better because rolling makes the grain structure stronger. This helps the threads resist breaking and wearing out. Compressive stresses at the root help the thread handle repeated loads. Cut threads break up the grain flow. This can make weak spots. You may see more failures with cut threads in tough jobs.

Rolled threads make stainless steel parts stronger and last longer. They also help the surface look and feel smoother. It is important to choose the right way to make threads for tough jobs. Profab Machine makes special stainless steel parts using smart machines and careful checks. New research says adding polymers and nanoparticles to thread rolling saves energy. It also makes the surface even better. Using the right oil and picking good materials are very important too. If you need something special, you can ask experts or get help from companies that know a lot.

FAQ

What makes rolled threads stronger than cut threads?

Rolled threads keep the metal grain flowing along the thread shape. This gives you higher strength and better fatigue resistance. You get parts that last longer and work better in tough jobs.

Can you use rolled threads for all types of metals?

You can roll threads on many metals, like stainless steel, titanium, and aluminum. Some brittle metals may not work well. Always check if your material can handle the rolling process.

How do you check the quality of rolled threads?

You use thread ring gages and thread plug gages to measure size and fit. You also look for cracks, seams, and smooth grain flow. Good inspection stops problems before they reach your customer.

Are rolled threads more cost-effective for large orders?

Yes, rolled threads save you money on big orders. The process is fast and wastes less material. You get more parts in less time, which lowers your cost per part.

What industries benefit most from rolled threads?

Industries like automotive, marine, medical, and aerospace use rolled threads. These fields need strong, reliable, and corrosion-resistant parts. Rolled threads help your products meet strict standards.

- Automotive

- Marine

- Medical

- Aerospace

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints