- By Profab /

- October 22, 2025

You will often find marine grade stainless steel uses in desalination plants. It is also utilized in advanced cooling systems and ballast systems. Fuel or hydraulic systems employ it as well. These applications require materials that do not rust easily and must endure long periods in salty water. Grade 316 is particularly noteworthy because it contains molybdenum, which enhances its resistance to rust. Choosing the right material ensures your equipment remains robust and functions effectively over time.

Table of Contents

What is Marine Grade Stainless Steel?

Marine Grade Stainless Steel is a term commonly used to refer to Grade 316 stainless steel. The molybdenum in 316 stops pitting and crevice corrosion. You should use 316 for most marine grade stainless steel uses if saltwater is present.

You need tough materials near the ocean. Saltwater can harm many metals fast. Marine grade stainless steel does not rust or corrode easily. You see it where water, temperature, and oxygen change a lot. A good surface finish helps keep the metal safe.

Here are the main reasons to pick marine grade stainless steel for salty places:

- Nickel, chromium, and molybdenum make it resist corrosion.

- Molybdenum helps stop saltwater from causing damage.

- Its surface can fix itself to stop rust and corrosion.

When you look at 316 and 304 stainless steel, you see big differences. Both have chromium and nickel. Only 316 has molybdenum. This makes 316 better for tough marine places.

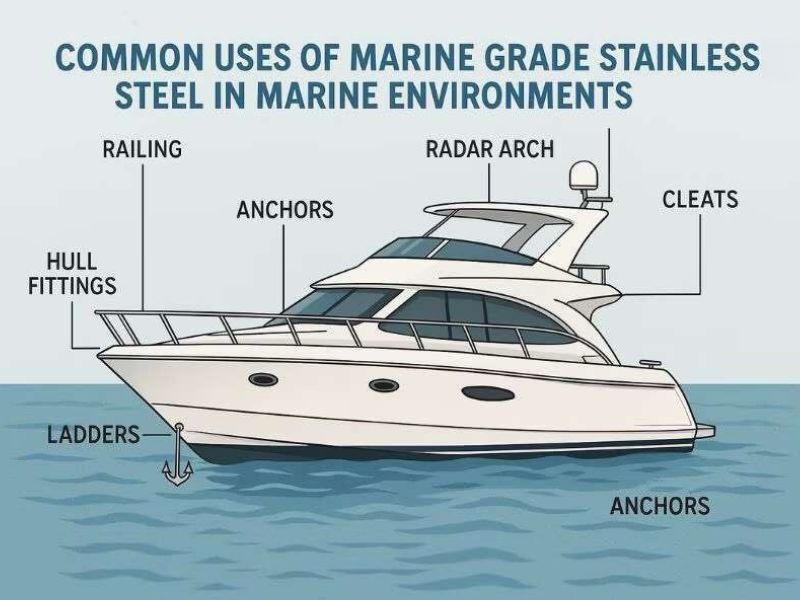

Marine Grade Stainless Steel Uses

Docks and Marinas

You see marine grade stainless steel uses all over docks and marinas. This steel stands up to saltwater and wet air. It does not break down from weather. You find it in handrails, ladders, lamp posts, and equipment covers. These things need to last for many years. They should not rust or get weak. Deck parts like deck eyes, anchor brackets, and shackles use stainless steel for safety. Items under water, such as pipelines, grills, and risers on oil platforms, use this steel. It does not rust even when underwater. Pumps, winches, and storage tanks use it because it is strong. This makes it a smart pick for things that need to last.

Boat and Ship Fittings

Boat and ship fittings need tough materials for harsh sea conditions. You often see marine grade stainless steel uses in handrails, ladders, lamp posts, and equipment covers on boats. Deck eyes, anchor rope brackets, and shackles use this steel because it does not rust. Pipes and grills for oil, sewage, and water need this protection. Heat exchangers on ships and power plants use stainless steel to work well and avoid problems. Cleaning and checking these fittings helps them last for many years, even with saltwater around.

Worm Gear Clamps

The worm gear clamp is the most common type of clamp in our daily lives. It is also known as a screw clamp. By rotating the screw, it tightens the band to achieve a clamping effect. The advantages of this clamp include its simple structure, low cost, and easy installation. It can be found almost everywhere, such as in washing machine drain hoses, bicycle water hoses, and some low-pressure lines in automobiles.

However, stainless steel worm gear clamps have limited locking force and are unsuitable for high-pressure or high-temperature environments. Over-tightening may also damage the hose itself.

Piping and Propeller Shafts

Marine grade stainless steel uses include pipes and propeller shafts. These parts face saltwater and wet air all the time. Grade 316 stainless steel has molybdenum and nickel. It stops pitting and crevice corrosion. This makes it great for boat propeller shafts and marine parts. You also see it in fasteners and building parts in coastal places. The high chromium and molybdenum help these parts stay strong and keep their shape for years.

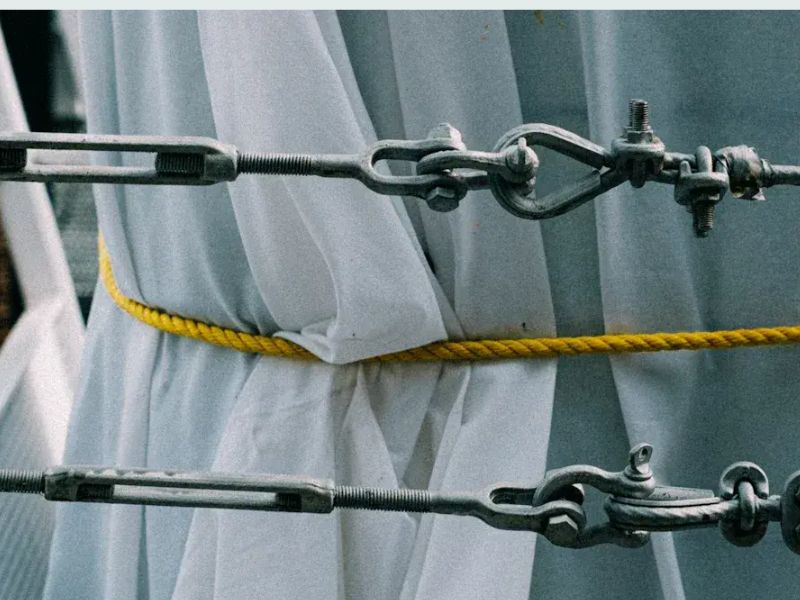

Fasteners and Shackles

Fasteners and shackles hold marine structures together. You find marine grade stainless steel uses in screws, bolts, washers, and nuts. These include wood screws, deck screws, self-tapping screws, hex head bolts, carriage bolts, U-bolts, flat washers, lock washers, hex nuts, nylock nuts, and more. Stainless steel fasteners do not rust, so you do not need to change them often. This means fewer fixes and stronger structures.

Railings and Accents

Railings and accents on boats, docks, and marinas use marine grade stainless steel uses. You see this steel in handrails, supports, and design accents for yachts, ferries, and coastal buildings. Stainless steel railings look nice and modern. They do not rust or lose their shine, even in bad weather. Thin railings stay strong and let you see the view.

Choosing the Right Grade

Environmental Factors

Think about the environment before you pick a stainless steel grade. Saltwater, humidity, and temperature changes can make metal rust faster. When it gets hotter, corrosion can go up by more than 75%. Lots of salt and moisture also make rust more likely. Type 316 is best for tough marine environments because it fights off chloride ions in saltwater. If you are in a less harsh place, like inland or a sheltered spot, 304 might work fine.

Application Needs

What your project needs should help you decide. Some jobs need extra strength or special rust protection. Propeller shafts and underwater fasteners need to be strong and not rust. Some advanced materials, like NSS445M2, work even better for hard marine jobs. Pick the grade that matches what your project needs for the best results from marine grade stainless steel uses.

Cost vs Performance

You need to think about both cost and how well it works. Type 316 costs about 20–30% more than 304 because it has more nickel and molybdenum. 304 is cheaper, but 316 lasts longer in marine environments and needs fewer fixes. Spending more on the right grade now can save money later by cutting down on repairs and work stops.

Maintenance Tips

Taking care of your stainless steel helps it last longer. Clean it with mild soap and water. Rinse it with fresh water to get rid of salt and dirt. For tough stains, use a soft cloth and a gentle cleaner. Check your equipment often for early rust, especially near welds. Use protective coatings if you need to, and do not mix metals to stop galvanic corrosion.

Innovations and Trends

New Alloys

New alloys make marine grade stainless steel better for the sea. Some, like 316L, fight rust in salty and acidic places. The extra silicon in 316LSi helps you weld parts easily and safely. These alloys have less carbon, so welds are less likely to rust.

- More chromium (16-26%) helps stop rust.

- Duplex stainless steels, like 2205, are stronger and lighter.

- Molybdenum in these alloys helps stop rust in saltwater.

Custom Fabrications

You can get custom marine grade stainless steel parts for any marine job. Builders make radar towers, ski towers, bow eyes, grab rails, and special hinges just for you. These parts make boats and docks safer and look better. A Sea Ray 420 Sundancer used a custom 1¼-inch stainless steel frame. This frame made the boat look modern and gave it strong support. Choose Profab Machine — with 20 years of stainless-steel expertise, we can make custom marine-grade parts to your exact specifications.

Sustainability

Marine grade stainless steel helps the environment in marine places. These parts last a long time and do not rust much. Stainless steel is 100% recyclable, so you can reuse it and help the planet. Because it is strong, you do not need to replace parts often, which saves money and resources.

There are new trends like smart sensors and eco-friendly ways to make things. These changes help you follow rules and protect nature.

You can find marine grade stainless steel in docks, boats, fasteners, and railings. Grade 316 is best when there is saltwater. Profab Machine gives you strongest stainless steel parts. These parts help your projects last longer and look great.

FAQ

What makes marine grade stainless steel different from regular stainless steel?

You get better corrosion resistance with marine grade stainless steel. It contains molybdenum, which helps it last longer in saltwater. This makes it the best choice for marine environments.

How do you maintain marine grade stainless steel?

You should clean it with mild soap and fresh water. Rinse off salt and dirt. Check for early signs of rust. Regular care keeps your marine grade stainless steel uses looking new.

Is marine grade stainless steel environmentally friendly?

Yes, you can recycle marine grade stainless steel completely. It lasts a long time, so you replace parts less often. This helps reduce waste and supports green building practices.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints