- By Profab /

- September 23, 2025

You can learn how to check ball joints on trucks and UTVs by looking for movement, damage, or unusual wear. Checking often keeps your vehicle safe and functioning properly. Manufacturers recommend checking ball joints at every oil change or alignment. These components wear out due to their constant movement. If you notice looseness, cracks, or hear any noise, you should address it quickly.

Table of Contents

Tools and Safety

Ball Joint Removal Tool

You need the right tools to check ball joints on your truck or UTV. Using the correct equipment makes the job safer and faster. One popular tool is the OEMTOOLS 24683 Ball Joint Tool. This tool works well with Polaris Ranger and RZR models. It helps you remove and install both upper and lower ball joints. The tool uses tough steel, so it lasts a long time. You do not need a shop press or hammer, which saves you time and effort. Even if a ball joint is stuck, this tool can help you get it out.

You may also need a jack, jack stands, wrenches, a dial indicator, and a pry bar. Always check your vehicle manual for any special tools.

Vehicle Prep

Prepare your truck or UTV before you start the inspection. Follow these steps for a smooth process:

- Lift the front of your vehicle and secure it on jack stands. Remove the wheel for better access.

- Disconnect the outer tie rod end using wrenches. Remove the brake line bracket from the steering knuckle.

- Measure the ball joint diameter and pick the right forked remover tool.

- Slide the remover tool behind the ball joint housing. Make sure the forked end cups the rear of the joint.

- Thread the press rod through the remover tool. Attach the pressure receiver tool to the end.

- Turn the press rod slowly to press out the ball joint. Check your progress often.

- Once the stud is out, remove the ball joint. Use a hammer if needed.

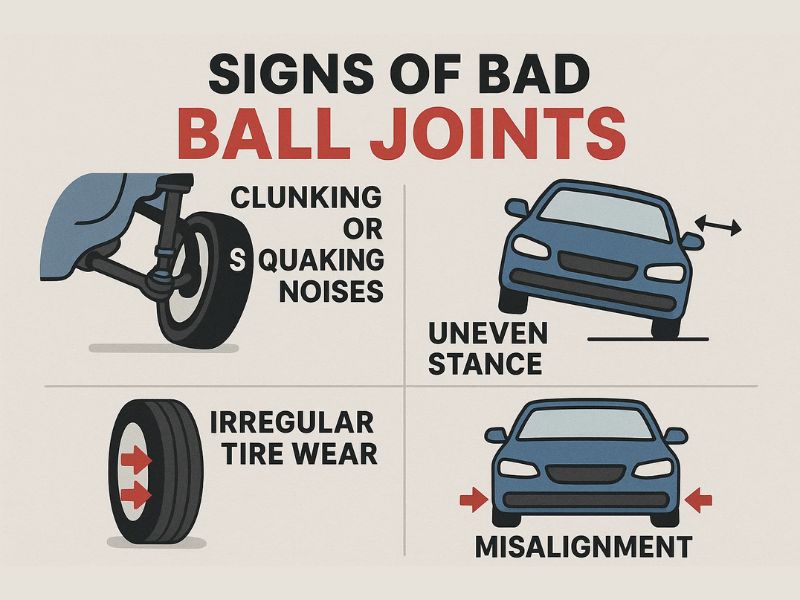

Signs of Bad Ball Joints

You can often spot bad ball joints by listening for unusual sounds. When you drive over bumps or turn the steering wheel, you may hear clunks, creaks, or metallic pops. These noises come from extra movement inside the joint. Worn ball joints lose their tight fit, so metal parts knock together. You might also notice sloppy steering. The wheel feels loose or disconnected, especially when you change lanes or drive at highway speeds. Your truck or UTV may start to feel floaty, making it harder to control.

Driving Symptoms

Bad ball joints affect how your vehicle handles on the road. You may notice several symptoms while driving. Here is a table showing common signs and what they mean:

Symptoms | Description |

Clunking noises | You hear metallic clunks when the suspension moves over bumps. |

Squeaking | Turning the wheel causes squeaks, often from a damaged rubber boot losing lubrication. |

Vibrations | You feel vibrations in the steering wheel or body due to loose ball joints. |

Pulling to the side when driving | Your vehicle drifts or pulls to one side, which means alignment is off. |

Loose or shaky steering | Steering feels unstable, making you lose confidence in control. |

Uneven tire wear | Tire tread wears unevenly, showing that suspension geometry is not correct. |

If you notice any of these symptoms, inspect your ball joints before driving further. These signs often mean the joint is worn and needs attention.

Visual Damage

You can spot many ball joint problems just by looking. Check for these signs:

- Cracks or obvious deterioration in the ball joint housing

- Damaged or torn dust boot

- Oil leakage around the joint

- Rust forming on metal surfaces

- Foreign objects stuck near the joint

A damaged boot lets dirt and water in, which speeds up wear. Oil leaks and rust show that the joint is not sealed well. Foreign objects can block movement and cause extra damage.

How to Check Ball Joints

Checking ball joints on trucks and UTVs keeps your vehicle safe and helps you spot problems early. You can follow these steps to inspect ball joints and avoid costly repairs. This guide shows you how to check ball joints using simple tools and clear methods.

Lift and Support Vehicle

Start by lifting your vehicle safely. You want to unload the suspension and expose the ball joints for inspection.

- Place the jack under the lower control arm. This helps unload the lower ball joint.

- Raise the vehicle until the tire is 5 to 6 inches off the ground.

- Support the vehicle with jack stands as close to the ball joints as possible.

- Use a pry bar or a sturdy 2×4 under the tire. Pull up gently while someone watches the ball joint for movement.

Tips

Visual Inspection

Look closely at each ball joint. You want to find signs of wear, damage, or leaks. Use a flashlight for better visibility.

Visual Sign | Description |

Axial Play | Raise the vehicle and check for up and down movement at the ball joint. |

Radial Play | Push and pull the tire at the 12 and 6 o’clock positions. Look for movement between the wheel knuckle and lower arms. |

Wear Indicator Design | On most models, check if the collar around the grease fitting is flush or recessed. Replace if needed. |

Chrysler Design | Wiggle the grease fitting. If it moves, replace the ball joint. |

Torn Boots/Noisy Movement | Discard ball joints with torn boots or any binding movement. |

Inspect the rubber boot for cracks or leaks. Grease or dust around the joint means the seal is broken. Replace any ball joint with a damaged boot.

Manual Play Check

You can check for play by moving the wheel by hand. This helps you feel looseness in the ball joint.

- Grab the tire at the top and bottom (12 and 6 o’clock).

- Push and pull to check for movement.

- Some vertical movement is normal, especially on older vehicles.

- You should not feel any side-to-side (lateral) movement.

- Excessive vertical play means you need to replace the ball joint.

Tips

Pry Bar Test

A pry bar test helps you spot hidden movement in the ball joint. Follow these steps:

- Make sure the vehicle sits securely on jack stands.

- Place a pry bar or 2×4 under the tire.

- Gently lever the wheel up and down.

- Watch for vertical play between the ball joint stud and housing.

- Check for looseness by lifting the tire with the pry bar.

If you see movement, the ball joint may be worn out. Replace it before driving again.

Listen for Noises

Noises can tell you a lot about ball joint health. Worn or loose ball joints often make faint, intermittent clunking sounds. You may hear these noises from one corner of your vehicle. The sound gets louder when you drive over bumps, dips, or make turns. If the noise grows louder or more frequent, inspect the ball joints right away.

Tire Wear Signs

Ball joints help keep your wheels aligned. Worn ball joints can cause uneven tire wear. Look for these signs:

- Inner or outer edge wear

- Feathering across the tread

- Cupping or scalloping

If you see these patterns, check the ball joints and alignment. Uneven tire wear means the suspension geometry is off.

Road Test

A road test helps you spot ball joint problems while driving. Pay attention to these symptoms:

- Audible noises like clunks or pops when turning or driving over bumps

- Sloppy or floaty steering, especially during lane changes

- Unstable front suspension, noticeable during braking or cornering

- Uneven tire wear, which may show up after misalignment

Drive at low and moderate speeds. Listen and feel for changes in steering or suspension. If you notice any of these issues, inspect the ball joints before driving further.

This guide shows how to inspect ball joints on trucks and UTVs safely. Check for play, uneven tire wear, torn boots, and leaking grease regularly. Use visual, manual, and road tests to confirm joint condition before repair. Profab Machine supplies precision stainless steel ball joints and bearings to improve fit and assembly reliability.

FAQ

How often should you check ball joints on trucks and UTVs?

You should inspect ball joints every oil change or at least every 25,000 miles. If you drive in rough conditions, check them more often. Regular checks help you catch problems early.

What tools do you need to check ball joints?

You need a jack, jack stands, a pry bar, and a flashlight. For precise checks, use a dial indicator. Some vehicles require special ball joint tools. Always follow safety steps when working.

What are the signs of a failing ball joint?

You may hear clunking noises, feel loose steering, or notice uneven tire wear. Look for cracked boots or leaking grease. These signs mean you should inspect and possibly replace the ball joint.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints