- By Profab /

- January 9, 2026

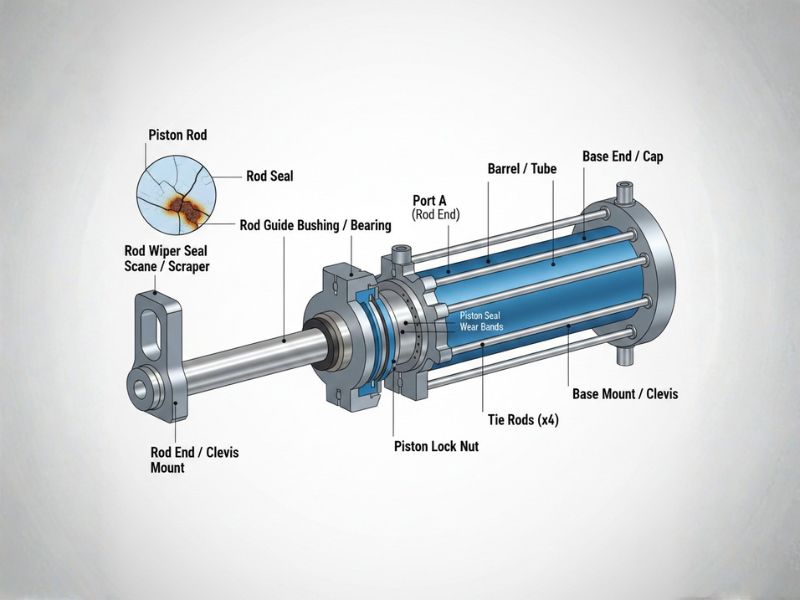

Hydraulic cylinders are often designed with generous safety factors for load and pressure. Yet in real-world applications, most cylinder failures are not caused by overload. Corrosion of external components is one of the main causes of machine downtime. Knowing where corrosion occurs helps improve protection. This article focuses on the three hydraulic cylinder components most likely to corrode. They are the piston rod, rod end, and clevis.

Table of Contents

Piston Rod: The Primary Corrosion Hotspot

Among all cylinder components, the piston rod is the most vulnerable to corrosion.

Why piston rods corrode first

The piston rod is continuously exposed to moisture, dirt, salt, and chemicals during operation. Every time the rod retracts, contaminants on its surface are pulled directly toward the seal system. Even rods with chrome plating are not immune. Microscopic cracks in the plating can allow moisture to reach the base material and initiate corrosion. Outdoor equipment, agricultural machinery, and coastal installations accelerate this process dramatically.

How rod corrosion leads to seal failure

Once corrosion begins, small pits form on the rod surface. These pits act like cutting edges against the rod seal, rapidly increasing wear. What often starts as minor surface rust can quickly result in oil leakage, pressure loss, and internal damage. In many cases, a cylinder that appears structurally sound becomes impossible to rebuild due to rod pitting.

Effective prevention methods

In corrosion-prone applications, material selection for the piston rod often has a greater impact on service life than increasing load capacity. Using stainless steel piston rods in corrosive environments is a better choice. You can also select higher-quality surface finishes and coatings.

Rod End: Small Component, System-Level Impact

Why rod ends fail before the cylinder

Rod ends are often positioned at the lowest point of the assembly, where water and debris accumulate. The spherical joint design naturally traps moisture, and standard carbon steel rod ends corrode quickly once protective coatings are damaged. In many real-world cases, rod ends seize or lose articulation long before the hydraulic cylinder itself shows visible damage.

How rod end corrosion damages the cylinder

A corroded or seized rod end restricts movement and introduces misalignment into the system. This misalignment transfers uneven loads back into the piston rod and seals, accelerating wear and increasing the risk of rod scoring and gland damage. Over time, a failed rod end can shorten the life of an otherwise healthy cylinder.

Recommended solutions

Matching rod end material and design to the operating environment rather than cost alone. Sealed spherical bearing designs to reduce moisture ingress. In many cases, a higher-quality rod end prevents far more expensive cylinder repairs later. Stainless steel rod ends for outdoor, agricultural, and marine applications.

Clevis: The Most Overlooked Corrosion Risk

Clevis connections are mechanically simple, which often leads to the assumption that they are maintenance-free. In reality, they are one of the most corrosion-prone joints in hydraulic systems.

Why clevis joints are prone to corrosion

The U-shaped geometry of a clevis naturally traps water and debris. Combined with a pin-and-hole connection, this creates ideal conditions for crevice corrosion. Once corrosion begins, protective coatings break down quickly, especially in outdoor or wash-down environments.

Common failures caused by corroded clevises

In many maintenance scenarios, the clevis itself does not fail structurally but turns a routine cylinder replacement into a time-consuming repair. When the clevis corrodes, it will seize in place and be hard to remove.

How to reduce clevis corrosion

Small improvements at the clevis connection often result in significant reductions in maintenance effort. You can apply proper lubrication and consider drainage during installation. Also stainless steel clevis is a good choice for hydraulic cylinder components replacement.

Corrosion is the “silent killer” of hydraulic systems. Heavy-duty cylinders are built to withstand immense pressure. But it is often the environmental exposure of the piston rod, rod end, and clevis that dictates the actual service life of the machine. Upgrading resistant materials like stainless steel can prevent catastrophic seal failure. Investing in a professional stainless steel components manufacturer today is the most effective way to ensure your hydraulic systems remain “field-ready” for years to come.

FAQ

Can I just sand down a pitted piston rod and keep using it?

Once a rod is pitted, the smooth surface required for a hydraulic seal is compromised. Sanding creates “low spots” that allow oil to bypass the seal or cause the seal to “nick” on the edges of the pits. For high-pressure applications, replacing the rod with a stainless steel piston rod is usually cheaper than constant seal replacements and fluid loss.

Why is my rod end seizing even though I grease it regularly?

Standard carbon steel rod ends often suffer from “crevice corrosion” where moisture gets trapped between the ball and the housing. If the environment is highly acidic or salty, grease alone can’t stop the chemical reaction. Switching to stainless steel rod ends or specialized sealed spherical bearings provides a physical barrier that grease cannot always maintain.

Is stainless steel worth the extra cost for hydraulic components?

Yes. While the upfront cost is higher than chrome-plated carbon steel, the ROI is realized through reduced downtime.

Send Inquiry Now

Related Resource

5 Types of Vehicles that Use Stainless Clamps

Chromoly Heim Joints vs Stainless Steel Heim Joints