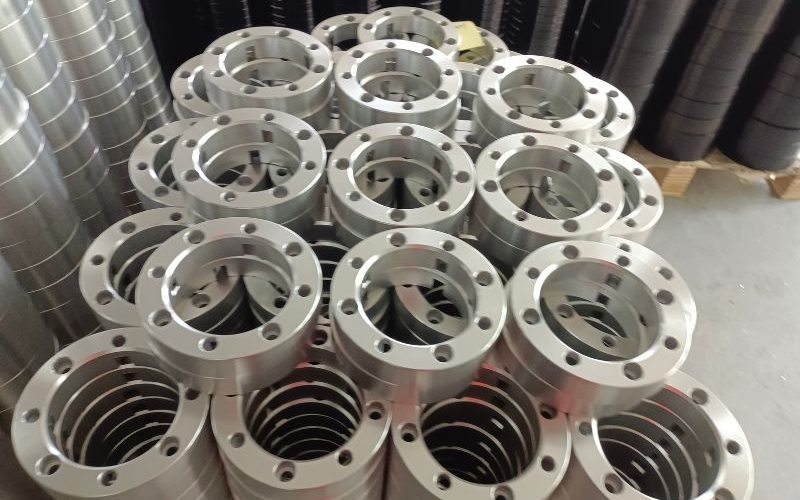

Stainless Steel Flange

Stainless Steel Flanges Manufacturer in China

A stainless steel pipe flange is a mechanical connector that joins pipes, valves, pumps, and equipment. Stainless steel flanges are typically circular discs with a central bore and bolt hole pattern. Two components join securely with a gasket between them to create the seal. It creates a secure, leak-tight environment to ensure safe, efficient fluid transport.

Profab stainless steel flanged fittings, unlike a permanent weld, provide a critical access point for cleaning, inspection, maintenance, or modification. This access is indispensable in many industrial environments.

- Suitable for high-temperature fluid systems

- Remarkable strength and durability

- Withstanding extreme pressures

- Resilience to temperature fluctuations

Explore Various Types of Profab Stainless Steel Flanges

Weld Neck Flange

Slip On Flange

Blind Flange

Threaded Flange

Socket Weld Flange

Lap Joint Flange

Plate Flange

Orifice Flanges

Custom SS Flange

Specifications

Parameter | Details |

Material Grades | 304, 316, 316L, Duplex, Super Duplex, Custom alloys |

Standards | ANSI/ASME, DIN, EN, BS, JIS |

Flange Types | Weld neck, Slip-on, Threaded, Blind, Socket weld, Lap joint, Reducing |

Sizes | ½” – 48″ (DN15–DN1200) |

Pressure Ratings | Class 150 – 2500 / PN6 – PN400 |

Connection Types | Raised face (RF), Flat face (FF), Ring-type joint (RTJ) |

Surface Finish | Machined, Polished, Passivated, Sandblasted, Black Oxide, Nickel Plated |

Testing & Certs | EN 10204 3.1 MTC, PMI, NDT, ISO 9001, PED |

Packaging | Wooden cases, Pallets, Export-safe protective wrapping |

Custom SS Flanges Manufactured To Your Drawings

Integrated Production from Prototype to Mass Production: We handle prototypes and mass production in-house. Faster lead times and consistent quality at every stage.

Extensive Material and Customization Capabilities: We offer 304, 316, and duplex stainless steels. Custom forging is available to your drawings.

Precision Manufacturing with Multi-Axis CNC: Multi-axis CNC machining delivers tight tolerances. Parts fit precisely for easy, leak-free installation.

Stringent Quality Control and Traceability: PMI checks and third-party inspection readiness. Full traceability for every product.

Application of Stainless Steel Pipe Flange

- Industrial: Used in chemical processing plants, food and beverage manufacturing, and waste treatment facilities for corrosion-resistant piping systems.

- Marine: Deployed in shipbuilding, offshore platforms, and marine equipment, where resistance to saltwater and harsh conditions is critical.

- Aerospace: Utilized in high-performance aircraft systems and engine components where lightweight, high-strength, and corrosion-resistant materials are essential.

- Solar Energy: Employed in mounting structures and piping for solar thermal collectors and power plants, requiring durability and resistance to environmental elements.

Why Choose PROFAB

With over 20 years of dedicated expertise in stainless steel, Profab Machine is your trusted partner for high-precision stainless steel flanges. We provide a comprehensive product line, from standard to custom-fabricated solutions, ensuring seamless integration into critical applications across the Industrial, Automotive, Aerospace, Solar Energy, Medical, and Marine sectors. Our commitment to precision manufacturing and rigorous quality control guarantees a superior product that meets your exact specifications.

- 20 Years Of Professional Manufacturing Experience

- Comprehensive solutions, not just products

- Comprehensive Surface Treatments

- Stringent Quality Control and Traceability

- Immediate response, regardless of project size

Flange Type | Primary Design Feature | Connection Method | Ideal Application | Pressure Suitability | Trade-Off/Limitation |

Weld Neck | Long tapered hub | Butt weld | High-pressure, critical systems (oil/gas, power generation) | High (Classes 150-2500) | Higher cost, complex installation, requires skilled welding |

Slip-On | Slides over pipe end | Two fillet welds | Low-pressure systems (HVAC, water treatment) | Low to medium | Lower strength, not suitable for critical applications with high stress |

Blind | Solid disc, no bore | Bolted | Sealing the end of a pipeline | All classes | Primarily for system termination or isolation, not for flow |

Threaded | Internal threads | Screwed onto pipe threads | Low-pressure, non-welded systems (hazardous environments) | Low | Limited to low pressure, not ideal for high-stress applications |

Socket Weld | Counterbore for pipe insertion | Fillet weld | Small-diameter, high-pressure pipes with limited space | High | Less total space required, but fluid must not be corrosive |

Lap Joint | Two-part design with a stub end | Bolted | Systems requiring frequent disassembly (food/beverage) | Low to medium | Higher cost than slip-on, but offers flexibility and ease of assembly |

Orifice | Machined pressure taps | Butt weld, threaded, or slip-on | Flow measurement (oil/gas, chemical processing) | Varies by design | Specialized purpose, used only for flow metering applications |

Frequently Asked Questions...

How to choose your ss flanges?

- Corrosion Resistance: The primary consideration is the nature of the fluid medium. The material must be able to withstand the specific corrosive agents present, such as acids, alkalis, or chlorides.

- Pressure and Temperature Requirements: The operational conditions directly determine the required mechanical strength and heat resistance. High-temperature applications, for example, may necessitate an H-grade material to prevent warping and system compromise.

- Weldability: The type of flange and installation method must be considered. For applications with numerous welded joints, the superior weldability of L-grades may be necessary to ensure long-term structural integrity.

What is the difference between your 304L and 316L stainless steel flanges?

While both are highly corrosion-resistant, our 316L flanges contain molybdenum, making them superior for applications in highly acidic or chloride-rich environments, such as marine and chemical processing.