- By Profab /

- August 19, 2025

Have you ever looked at a wide range of hardware and felt lost? The Profab Machine will explore the world of threaded rods with you as you look at different sizes, materials, finishes and strengths for different applications.

Table of Contents

What Is A Threaded Rod

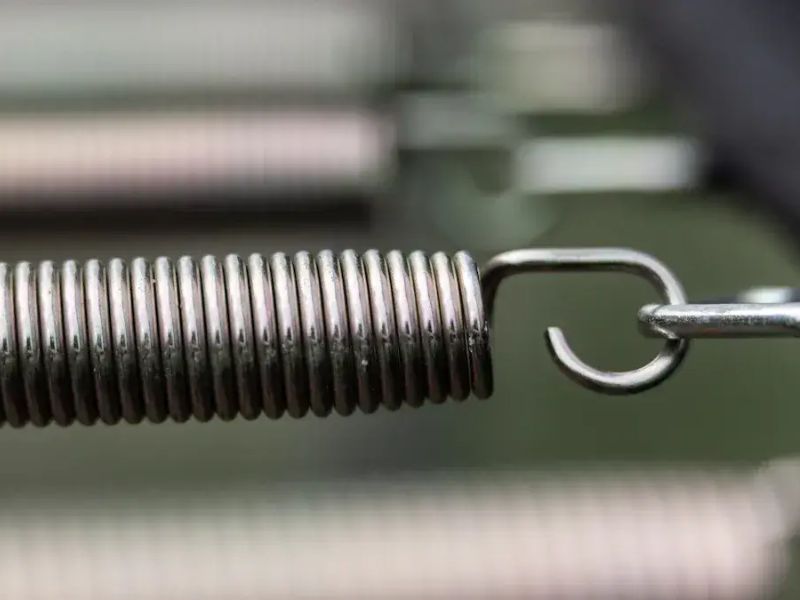

Threaded rods look like long, straight metal rods with spiral grooves running along their length. Commonly, there are fully threaded rods and half threaded rods. Unlike a regular bolt, it has no head. You can screw a nut on either end. This design allows you to securely attach objects or hold them in place. It works by converting rotational force into strong force.

Common sizes include UNC (coarse thread), UNF (fine thread), and metric thread. Threaded rods are typically made of steel, stainless steel, brass, and titanium.

Threaded Rod Material Selection

Choosing the right material for your threaded rod is critical. Each metal has its scenarios, advantages and disadvantages.

Steel

Steel threaded rod is versatile and can be found in construction, mechanical and home projects. Steel is strong, durable and not too expensive. If you need to carry heavy loads, steel threaded rod is a good choice.

Pros:

- Very strong for building and bracing

- Great work at a great price

- Multiple sizes, easy to find

Cons:

- Rusts quickly if exposed to moisture

- Coating required for outdoor use

- Not as rust-resistant as stainless steel

Steel rods are best suited for dry or indoor locations. If used outdoors, choose galvanized or hot-dip galvanized. These coatings help prevent rust, but are not as durable as stainless steel in inclement weather.

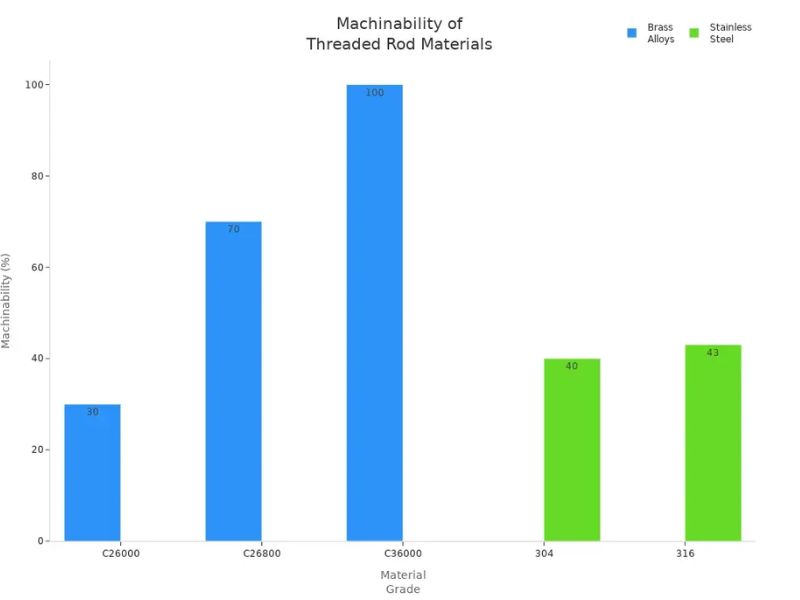

Stainless Steel

Stainless steel contains chromium, which creates a protective layer against rust. You can find this type of threaded rod in ships, food factories and chemical plants.

Pros:

- Effective against rust even in salt water

- Long-lasting

- Works in hot, cold or wet places

- Requires little care

Cons:

- Costs more than steel or brass

- Not as strong as some special alloy steels

Stainless steel bars come in different grades. grade 304 is suitable for most applications. grade 316 is best suited for seawater and chemicals, making it ideal for marinas and ships. Other grades, such as 310, can withstand extremely high heat, so they can work in furnaces or power plants.

If your project is located in harsh conditions, use stainless steel. Stainless steel lasts longer and saves you money in the long run.

Below is a comparison of the properties of different types of steel:

Material Type | Strength Characteristics | Common Applications |

Carbon Steel | Very strong but rusts easily | Used for steel frames and foundation bolts |

Stainless Steel (304,316) | Does not rust and lasts a long time | Used in boats, chemical plants, and food factories |

Galvanized Steel | Has extra protection from rust | Used outside and in big building projects |

High-Strength Alloy Steel (ASTM A193, A325, A354) | Very strong and tough | Used for heavy machines, bridges, and nuclear plants |

Brass and Beyond

Brass threaded rod is shiny and resistant to rust, but not as strong as steel or stainless steel. Brass is suitable for light engineering, electrical work, and where aesthetics are desired. Brass rods are commonly used for pipes, heat exchangers and decorative items.

Pros:

- Good for transmitting electricity and heat

- Easy to cut and shape

Cons:

- Not as strong as steel or stainless steel

- Wears out faster if used for heavy loads

- Will rust in salty or acidic places

Other materials include titanium, Inconel, and PTFE Titanium rods are lightweight, strong, and resistant to rust. Inconel rods are suitable for high temperature or salty environments. PTFE rods are less susceptible to damage from chemicals or high temperatures, but are less strong. These specialty rods are more expensive and are primarily used in aircraft, chemical plants and high tech areas

Below is a comparison of the performance of different materials of threaded rod compiled for you:

Property | Brass (Typical Alloys) | Stainless Steel (Typical Grades) | Carbon Steel (General) |

Tensile Strength | 250–500 MPa (e.g., 340–470 MPa) | 500–1100+ MPa (e.g., 505–1550 MPa) | Generally stronger than brass, but less corrosion resistant than stainless steel |

Yield Strength | ~40–260 MPa | Higher than brass, varies by grade | Not explicitly detailed |

Hardness (Brinell/Rockwell) | 55–73 BHN (Brass alloys) | 146–595 BHN; up to 50 HRC (e.g., AISI 420) | Not explicitly detailed |

Elongation | 2.5–66% (varies by alloy) | Up to 40% (e.g., 40% elongation in AISI 316L) | Not explicitly detailed |

Corrosion Resistance | Lower; brass corrodes faster, especially in saltwater (dezincification) | High; chromium (10–30%) forms protective oxide layer, superior in harsh environments | Lower than stainless steel |

Thermal Conductivity | High (~109 W/m·K) | Low (~16 W/m·K) | Not specified |

Electrical Conductivity | High (15.9 × 10⁶ S/m) | Low (1.32 × 10⁶ S/m) | Not specified |

Wear Resistance | Lower; wears faster under friction | Higher; better wear resistance due to chromium and nickel content | Not specified |

Typical Applications | Electrical connectors, heat exchangers, low-stress fixtures | Structural supports, fasteners, medical instruments, harsh environments | Generally used for strength but less corrosion resistance than stainless steel |

Sizes Of Threaded Rod

Measuring Diameter

Determining the proper diameter is the first step. You want the threaded rod to fit perfectly, so use calipers for the most accurate measurement. Place the jaws on top of the threads, not in the grooves. Hold the caliper at a slight angle so it doesn’t slip into the groove.

If you don’t have calipers, you can use a nut or bolt gauge. Simply screw the rod into the tester until you find the right spot. Always double check your measurements and make sure the threads are clean. Good lighting helps you see the details.

Use a pitch gauge to match the thread profile and confirm the pitch at the same time.

Length Selection

Select the appropriate length and make sure there is enough room at both ends to install the nut and washer. Measure the distance you need to span and increase it slightly for adjustment. If custom sizes are required, the rod can be cut with a hacksaw or power tool. Remember to file the ends flat to allow the nut to fit easily. Always check the drawing before cutting and measure carefully to avoid mistakes.

Thread Type and Pitch

Pitch is the distance between each thread. For inch rod, count the number of thread crests in an inch; for metric rod, measure the distance between threads.

Coarse threads: faster assembly, better for harsh conditions, less strength under high tension.

Fine thread: stronger, more accurate, but requires cleaner conditions.

Thread Engagement

Thread engagement is the amount that the threads of a rod engage in a nut or threaded hole. For most steel rods, the engagement length of the nut should be at least as long as the diameter of the rod – so a 1/2-inch rod requires at least 1/2-inch of threads in the nut.

If softer materials are used, a greater amount of engagement may be required. Insufficient engagement can cause the nut to slip or the joint to fail. Too much engagement can make it difficult to tighten and may damage the fastener. For full strength, aim for 1 to 1.5 times the rod diameter at thread engagement.

Load and Strength of Threaded Rod

Load and strength is an important factor when selecting threaded rod. Every threaded rod has a limit called tensile strength. This indicates how much tension it can withstand before it breaks. Yield strength is another value. It indicates at what point the threaded rod begins to bend and cannot return to its original shape.

Strength varies by grade and material. Industry standards like ASTM and SAE can help you understand the expected performance of each rod. These standards specify the strength, hardness, and even the appearance of the rod. When you see a grade on a threaded rod, you know it meets certain safety and quality regulations.

For example, ASTM A307 rods do easy work, while ASTM A193 Grade B7 or SAE J429 Grade 8 rods are stronger. These high-strength bars are often used in places like bridges or heavy machinery. Stainless steel rods are not as strong as some alloy steels, but they are rust resistant.

The table below will help you compare some of the common grades:

Grade / Material | Diameter Range | Proof Load (ksi) | Yield Strength (ksi) | Tensile Strength (ksi) | Common Uses |

ASTM A449 | 1/4″ – 1″ | ~85 | ~92 | ~120 | Engineering, construction |

ASTM A193 Grade B7 | 1/4″ – 2-1/2″ | – | 105 | 125 | Oil, gas, high temp/pressure |

SAE J429 Grade 2 | 1/4″ – 1-1/2″ | 33 | 36 | 60 | General use |

SAE J429 Grade 8 | 1/4″ – 1-1/2″ | 120 | 130 | 150 | Automotive, heavy-duty |

Stainless Steel B8 | All sizes | – | 30 | 75 | Corrosion resistance, marine |

Finish Options for Threaded Rod

Coatings on threaded rod help protect against rust, chemicals, and the effects of weather. The main types are as follows:

Plain Finish: Uncoated. For indoor use in dry locations only. No rust protection.

Galvanized: Thin zinc coating. Suitable for indoor or light outdoor use. Some rust protection.

Hot-dipped galvanized: thick zinc coating. Best for outdoors, wet or near water. More durable than galvanized coating.

Stainless Steel: No coating required. The metal itself is rust and chemical resistant. Great for outdoor, marine or chemical use.

Specialty Coatings: Some rods come with powder or special coatings for added safety. These rods are great for special jobs or green projects.

If you need a rod for use on a dock, boat, or near salt water, choose 316 stainless steel or Inconel. these rods will not rust and will last for years, even in harsh environments.

Installation Tips

Cutting Threaded Rod

First, mark the exact location where you want to cut. Screw two nuts onto the rod and tighten to align with each other as marked. These nuts act as guides and help protect the threads. Use a hacksaw or a saw with a metal blade. Start cutting slowly so the saw does not slip and damage the threads. Hold the bar steady and finish the cut smoothly.

After cutting, use a file to sand down any sharp edges or burrs. They help realign the threads when removing the nut, making it easier to tighten the nut later. If more than one rod needs to be cut, use the first cut as a reference to guide subsequent cuts.

Always wear goggles and gloves to protect yourself from sharp debris when cutting metal.

Washers and Nuts

Washers and nuts do more than hold objects in place. The right washer distributes the force of the nut, which protects the material and keeps the connection strong. Flat washers increase surface area so they don’t crush wood or metal. Lock washers prevent the nut from loosening when shaken or moved. Spring washers absorb shock and help keep loads stable.

Proper use of the washer and nut combination helps prevent damage and ensures a more durable threaded rod connection. Use washers to help reduce stress on the first few threads. This prevents the rod from breaking under heavy loads.

Tools

The tools you will need depend on where you are installing the threaded rod. If it’s concrete, you’ll need a drill to drill a pilot hole, some anchor bolts to hold the rod in place, and a nut driver to tighten all the pieces. If it’s wood, you can use self-tapping anchor bolts, which don’t require pre-drilling.

Always make sure the nut and washer match the size and thread type of the rod. Use a torque wrench to tighten the nut to the right degree – too tight will damage the rod, too loose is unsafe. If extra security is needed, apply thread locker before tightening the nut.

Choosing a supplier with reliable threaded rod can make your project easier. Profab Machine has been drilling in stainless steel for more than 20 years, offering a wide range of sizes. We have a cash-based machining center with specialized inspection equipment to ensure your project goes perfectly.

FAQ

How do you know which size threaded rod to buy?

Measure the span you need. Measure the diameter with calipers. Check the length of the project plan. Be sure to allow some allowance for nuts and washers.

Can you cut threaded rod at home?

Yes, you can. Mark the location, install two nuts, and then use a hacksaw. File the ends flat. Remove the nuts and secure the threads. Be sure to wear goggles and gloves for protection.

What is the best material for outdoor use?

Stainless steel is best for outdoor use. It is rust resistant and durable. Hot-dip galvanized rods also perform well in wet areas. Choose the appropriate finish for your local weather.

Does every threaded rod need a washer?

Washers help spread the load and protect your project. Washers should be used on most jobs. Lock washers keep nuts tight when objects wobble or move.

Can I use threaded rod to carry heavy loads?

Yes, but you must select the correct grade and diameter. Check the package for load ratings. Strong alloy steel rods are suitable for large projects.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints