- By Profab /

- August 26, 2025

Both processes, electrolytic polishing and passivation, are widely used in a variety of industries. Electropolishing is best suited for parts that must be very clean and smooth, such as medical implants and aircraft parts. The passivation process is less expensive and provides good protection against rust. It is suitable for parts that are simple in construction or do not have high cosmetic requirements.

The choice between electrolytic polishing and passivation should be based on a combination of surface requirements, rust protection, cost and regulations.

Table of Contents

Electropolishing

Electrolytic polishing is a special method of polishing metals. It uses electric current and chemicals to make the metal smooth and shiny. The metal parts are placed in an acidic solution and then connected to a power source. The surface of the metal sheds fine particles, which help remove rough spots. After polishing, the metal looks clean and bright. Electrolytic polishing will not scratch or damage parts. It can be used on stainless steel, copper and titanium.

Benefits:

- Safer, bacteria don’t stick as easily.

- Removes small burrs, cracks and tool marks, making parts easier to clean.

- Has better resistance to rust and corrosion.

- Suitable for complex shapes and does not cause damage.

Applications:

- Medical device stents, surgical tools and implants.

- Aerospace industry.

- Electronics and semiconductor industries.

- Automotive and racing teams.

Passivation

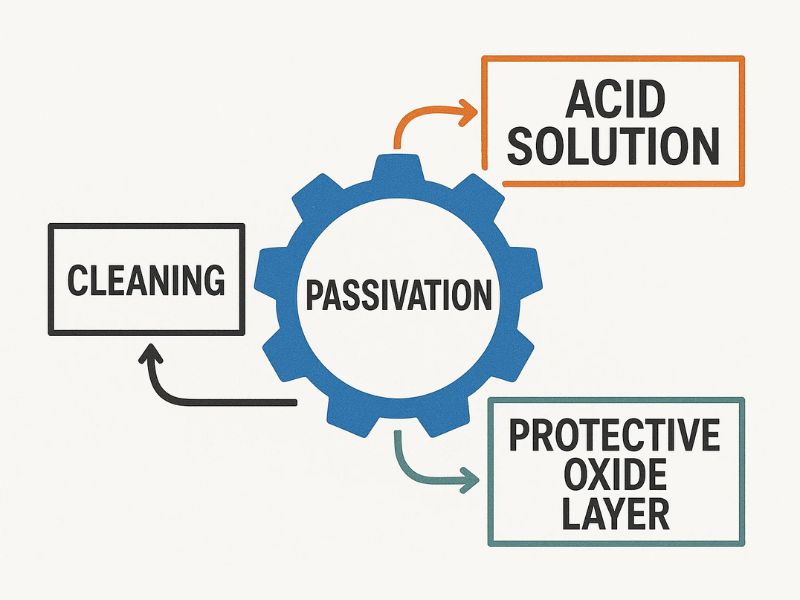

Passivation is a chemical process that helps prevent rust. After cleaning metal parts, they are placed in an acid bath containing nitric or citric acid.

The acid will remove free iron from the surface. Free iron, if left behind, can lead to rust. After the acid bath, the parts are rinsed with water. As the part dries and is exposed to air, the chromium in the metal reacts with oxygen to form a thin, invisible layer of chromium oxide.

This layer of chromium oxide acts as a barrier, keeping water and chemicals out of the metal. Over the next day or two, this protective layer becomes stronger. The process does not change the look or feel of the metal, it simply strengthens the surface.

Citric acid is safer for the planet and is good for mild operations. Nitric acid is more commonly used in larger factories.

Benefits:

- It prevents rust even in wet or salty areas.

- The process removes tiny bits of iron and dirt, so surfaces are cleaner.

- Passivated parts last longer and require less restoration.

- The metal maintains the same appearance and size, which is favorable for small parts.

- You can easily clean and sanitize passivated surfaces, which helps with medical and food work.

Applications:

- Mixing tanks, dairy and brewing equipment

- Cutting tools, storage containers

- Food processing machines

- Medical device components requiring corrosion resistance

Electrolytic Polishing VS Passivation

Electrolytic polishing is suitable for all stainless steels, even welded or brazed parts. Passivation is not as effective on welded parts or on certain steels with low chromium content.

Surface Preparation

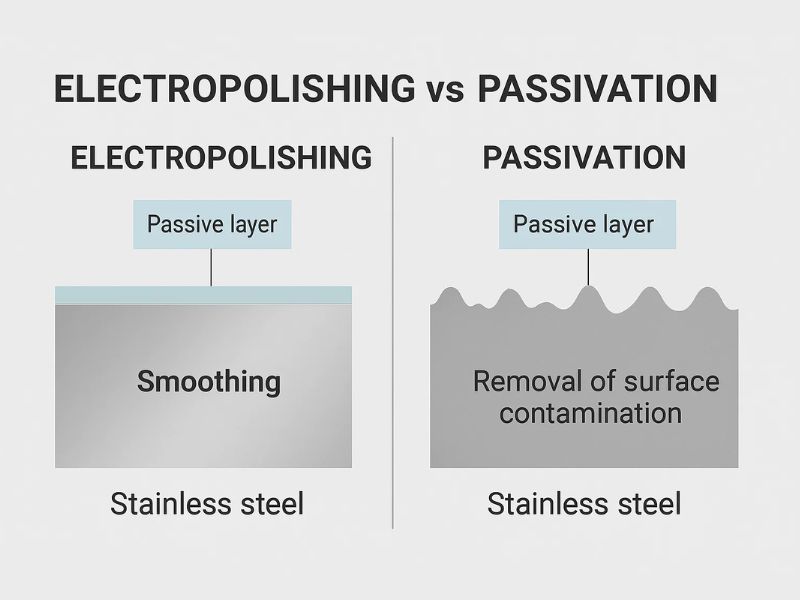

Electrolytic polishing and passivation treatments have different effects on the appearance of the metal. Electrolytic polishing removes tiny dings, bumps and scratches, making the metal shine like a mirror and improving surface smoothness by up to 40%.

Passivation does not change the look or feel of the metal, it simply cleans the surface and prevents rust.

Electropolishing also removes the layer of damage caused by earlier polishing. The end result is a layer of pure metal. Passivation increases the chromium to iron ratio, which helps prevent rusting, but does not result in a smoother surface.

Corrosion Resistance

Electrolytic polishing provides better protection. Electrolytically polished surfaces have a thin, uniform oxide layer. This oxide layer prevents pitting and reduces nickel release, which is important for medical and food tools.

Passivated surfaces have a thicker oxide layer, but tend to crack and release more nickel.

Tests have shown that electrolytic polishing reduces rusting by more than 60 times compared to untreated metal. Best results are obtained when electrolytic polishing and passivation are used together.

Cost

Passivation is initially less expensive. It uses simple tools and fewer steps. It can be used as part of routine maintenance.

Electrolytic polishing is more costly because it requires a special polishing tank and power supply. However, it is possible to do both jobs at the same time. It extends the life of parts and reduces the number of replacements. Using a machine can reduce the cost of batch electrolytic polishing. If you are looking for the best long-term benefits, then electrolytic polishing is often the smarter choice for dealing with tough problems.

If you want to save money now, you can opt for passivation. If you want to reduce the amount of work and extend the service life, electrolytic polishing is a better choice.

Materials

Some metals, such as inconel and stainless steel, are better suited for electrolytic polishing. Electropolishing removes minor imperfections and gives the metal a smoother surface.

Passivation is suitable for low carbon stainless steels, it creates a protective layer but does not change the appearance of the metal.

If you are using stainless steel with high carbon content, electrolytic polishing is more effective in preventing rough spots and pitting.

Above is the comparison between electrolytic polishing and passivation. We hope it will help you in selecting the surface treatment. Profab supports many kinds of surface customization services. Looking forward to your inquiry.

FAQ

What metals can be electrolytically polished or passivated?

Stainless steel, titanium, copper and some nickel alloys can.

Does electrolytic polishing change the size of the part?

Electrolytic polishing removes a very thin layer of metal, less than 0.001 inches thick. You won’t notice much of a change in size. It helps smooth out sharp edges and minor imperfections.

Can electrolytic polishing and passivation be used at the same time?

Yes, both processes are fine. Electropolishing smooths the surface and removes imperfections. Passivation provides better protection against rust after electrolytic polishing.

Is electrolytic polishing safe for food and medical parts?

Electropolished parts are safe for food and medical use. The process removes dirt and makes the surface easy to clean.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints