- By Profab /

- August 1, 2025

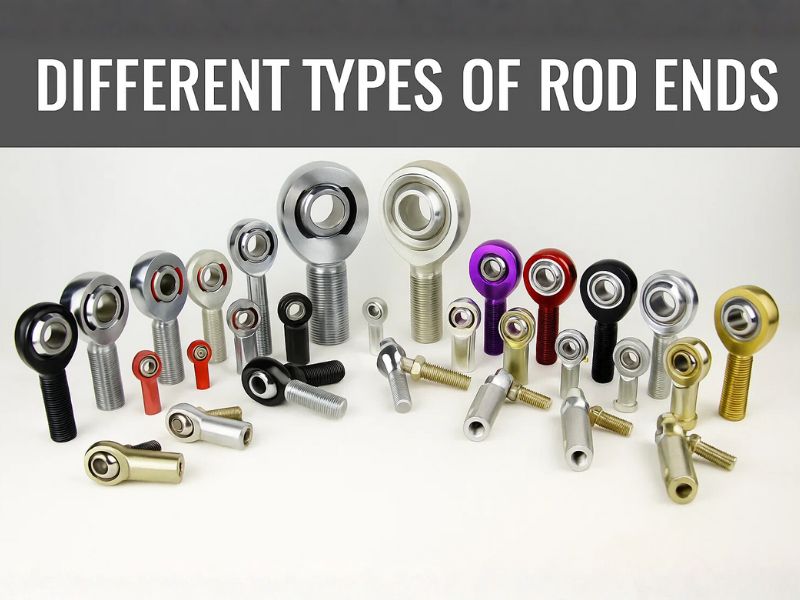

Rod end bearings, also known as heim joints or spherical rod ends. They typically consist of three main components: an outer race, an inner ball, and a rod body. In the following sections, Profab Machine will introduce the primary classifications of rod ends based on lubrication type, structural design, and material composition.

Table of Contents

By Lubrication Type

Self-Lubricating Rod End Bearings

Self-lubricating rod ends typically feature housings made from carbon steel, alloy steel, or stainless steel. These rod ends use an internal liner to provide continuous lubrication, with PTFE being the most common liner material.

PTFE-lined rod end bearings perform best within a temperature range of approximately -65°F to 325°F. They offer long service life, low maintenance requirements, and excellent vibration and noise reduction. This makes them ideal for systems that experience frequent motion or continuous vibration.

Greaseable Rod End Bearings

These rod end bearings are designed with an integrated grease fitting that allows for periodic relubrication. Their race includes grease grooves to ensure effective distribution of lubricant. Rod ends with grease fittings are typically made from carbon steel with a silver-zinc coating. They generally operate within a temperature range of -30°C to +60°C.

Greaseable rod ends are well-suited for heavy-duty applications. Regular lubrication helps flush out abrasive particles and extend component life. These rod ends are commonly used in agricultural machinery, gardening equipment, pneumatic and hydraulic systems, fitness equipment, and other demanding environments.

Metal-To-Metal Rod Ends

This is the simplest design of rod end bearings. The spherical inner ring slides directly on the metal surface of the race without any internal lubrication or liner. The housing is typically made of carbon steel with silver-zinc or yellow-zinc plating, while the ball is made of carbon steel or 52100 bearing steel.

Metal-to-metal rod ends are known for their high strength and excellent high-temperature resistance. The steel-on-steel sliding contact surface can operate within a temperature range of -50°C to +200°C. This type of rod end is ideal for off-road vehicles, racing applications, aerospace systems, heavy machinery, and other demanding environments.

By Structural Design

Two-Piece Rod End Bearings

These rod end bearings are characterized by a separate outer housing and a spherical inner ring. The housing is typically made of carbon steel, chromoly steel, or stainless steel, while the ball is usually manufactured from 52100 bearing steel. Two-piece rod ends generally offer a misalignment angle of 5° to 20°.

They are well-suited for heavy-duty applications and are commonly found in components such as A-arms, control arms, trailing arms, radius rods, tie rods, drag links, and track bars.

Three-Piece Rod End Bearings

Three-piece rod ends typically feature a 4130 chromoly or carbon steel body with a 52100 bearing-steel ball. Compared with two-piece designs, the three-piece construction adds a separate race, which improves load distribution and significantly enhances durability. These rod ends are ideal for high-cycle and high-vibration environments.

For example, JMX/JFX series rod ends offer static radial load ratings ranging from 2,800 lbs to over 100,000 lbs. Three-piece rod ends are most commonly used in racing applications such as shifter linkages, suspension linkages, sway bar assemblies, and control arms.

By Material

Carbon Steel Rod Ends

These rod ends are the most commonly found in mass-production vehicles and general machinery. They offer high strength, low cost, and excellent overall value. The bodies are typically zinc-plated or chrome-plated for basic corrosion resistance. However, their service life is shorter in salt-spray or highly corrosive environments.

Carbon steel rod ends meet the needs of most industrial machinery, agricultural equipment, and standard automotive suspension linkages.

Chromoly Steel Rod Ends

Chromoly steel rod ends offer exceptional strength and high fatigue life. They are engineered to withstand extreme impact loads and bending stresses. Compared with standard carbon steel, chromoly is lighter, making it ideal for performance-focused applications.

Its excellent weldability makes it a preferred choice for custom control arms, linkages, and steering systems. However, chromoly rod ends still require proper surface treatments to ensure adequate corrosion protection.

Stainless Steel Rod Ends

This type requires no plating. Although the initial cost is slightly higher, its long service life and low maintenance more than make up for it. Stainless steel rod ends are an excellent fit for performance builds and off-road enthusiasts. They continue to perform reliably even in mud, salt spray, high humidity, and elevated temperatures. Beyond automotive use, stainless steel rod ends are also a strong choice for marine applications and industrial environments with high corrosion exposure.

Aluminum Rod Ends

Aluminum rod ends are very lightweight due to the low density of the material. They are the go-to choice in high-performance modification applications where extreme weight reduction is desired. For example, sway bar links in racing vehicles typically experience relatively low loads but demand high responsiveness and minimal weight.

Although aluminum offers natural corrosion resistance, its ultimate strength and fatigue resistance are lower than chromoly or carbon steel. Anodizing is often applied to further enhance both strength and corrosion protection.

Titanium Rod Ends

Titanium alloy, often called the “space metal,” combines extreme lightness with incredible strength. Its density is only about 60% that of steel, which translates to faster response, lower inertia, and improved fuel efficiency. Titanium maintains excellent corrosion resistance even under prolonged exposure to harsh environments. Its superior fatigue performance allows it to withstand repeated high-impact loads without failure, making it the material of choice for aerospace, military applications, and top-tier extreme racing vehicles.

Plastic Rod Ends

Plastic rod ends offer advantages such as self-lubrication, lightweight construction, corrosion resistance, and low cost. Their strength is relatively low, making them suitable for low-load and low-torque linkage systems.

More Special Rod Ends

Here are some tips for choosing rod ends:

Factor | Key considerations | Impact on performance |

Loads (static and dynamic) | Tensile/compression/alternating loads, impact loads, load direction changes | Durability, service life, noise, potential for permanent deformation (Brinell indentation) |

Type of exercise | Rotational motion, oscillation angle, low-amplitude alternating motion | Smoothness, friction, service life, noise/vibration |

Operating Environment | Dust/contaminants, corrosive/humid environments, chemical exposure | Wear, corrosion, reliability, lifespan |

Temperature range | Min./max. operating temperature, coefficient of thermal expansion | Material properties, lubricant effectiveness, load capacity |

Misalignment angle | Required articulation angle, installation error, structural deformation | Stress concentration, system flexibility, wear, smooth operation |

Maintenance requirements | Lubrication accessibility, regular maintenance capabilities | Downtime, operating costs, lifespan, reliability |

Material selection | Strength, weight, corrosion resistance, wear resistance | Load capacity, lifespan, environmental adaptability, cost |

Cost-effectiveness | Initial cost, maintenance costs, life expectancy, performance requirements | Total cost of ownership, return on investment |

Although compact in size, rod end bearings play a crucial role in countless mechanical systems。 They ensure smooth operation across a wide range of industries. Profab Machine built its reputation on high-quality rod ends. No matter the material or design you require, our factory can deliver. With state-of-the-art CNC machining centers and a team of professional experts, we look forward to partnering with you.

FAQ

What are the common causes of rod end bearing failure? How can they be prevented?

Common causes of failure include:

- Insufficient lubrication: This is the leading cause of failure and can lead to increased friction, excessive wear, and seizure.

- pollute: Dust, dirt, water, or metal particles can damage the bearing lining and accelerate wear.

- Overload: Exceeding design limits can result in permanent deformation or surface fatigue.

- Assembly Error: Improper installation or torque may cause premature failure.

- Prevention: Regular inspection, proper lubrication, cleanliness, proper installation (follow manufacturer’s instructions and use a torque wrench), protection of seals/dust boots, and prompt replacement of worn parts.

Send Inquiry Now

Related Resource