- By Profab /

- December 29, 2025

When comparing chromoly heim joints vs stainless heim joints, you might wonder which option is best for your project. Chromoly heim joints are extremely strong and can support heavy loads, while stainless heim joints offer excellent resistance to rust, making them ideal for wet environments. The differences between chromoly heim joints vs stainless heim joints include cost, durability, and performance in various conditions. Your choice between chromoly heim joints vs stainless heim joints should depend on your specific application and environment.

Table of Contents

Strength & Durability

Chromoly heim joints are known for being very strong. This strength comes from a special steel called 4130 chromoly. Makers heat-treat these joints to make them even tougher. Heat-treating means the metal can handle more stress. Chromoly heim joints can hold heavy things and take hard hits. Many people who race off-road or build tough vehicles use chromoly. It does not bend or break easily. Hard chrome finishes and bearing steel help them fight wear.

Stainless steel is tough and does not wear out fast. It’s not as strong as chromoly. But it is usually softer than heat-treated chromoly. Stainless steel heim joints can handle normal use and medium loads just fine. They keep their shape well, but may not last as long as chromoly in really hard jobs. Stainless heim joints are best where rust is a big problem. They will not rust easily in wet or salty places. These heim joints are a good choice for boats or outdoor projects.

Environmental Performance

You need to think about how your heim joints will handle water, salt, and dirt. Chromoly heim joints can rust if you do not protect them. They have a strong steel base, but moisture and road salt can eat away at the metal. Most chromoly joints come with a coating or plating. This helps stop rust, but the protection can wear off over time. If you use your vehicle in wet or muddy places, you may see rust spots on chromoly joints after a while.

Stainless heim joints work better in harsh environments. Stainless steel does not rust easily. You can use these joints in rain, snow, or salty air. They keep their shine and strength much longer. You do not need to worry about coatings wearing off. If you want less maintenance, stainless is a smart choice.

Price Comparison

When you compare prices, you will see a clear difference between chromoly and stainless heim joints. Chromoly heim joints usually cost less than stainless ones. This lower price comes from the materials and the way manufacturers make them. If you need to buy many joints for a big project, chromoly can help you save money up front.

Here is a simple table to show the price difference:

Type | Average Price (each) |

Chromoly Heim Joint | $20 – $40 |

Stainless Heim Joint | $35 – $60 |

You may notice that stainless heim joints cost more. The higher price comes from the extra corrosion resistance and the cost of stainless steel. If you work on a tight budget, chromoly heim joints might fit your needs better.

Long-Term Value

Price is not the only thing you should think about. You also need to look at long-term value. Chromoly heim joints are designed for cyclic fatigue resistance, meaning they can flex and take hits repeatedly without snapping. If you live in a humid or snowy area, you will spend money on rust inhibitors or rubber dust boots to keep the housing from pitting.

Stainless steel heim joints resist rust, but they can wear out faster in high-stress jobs. Stainless heim joints are worth the investment if you need the best rust protection. They work well in wet or salty places, even if they cost more at first. Think about where and how you use your vehicle. This will help you choose the best value for your needs.

Maintenance & Lifespan

Upkeep Needs

You need to pay attention to maintenance if you want your heim joints to last. Chromoly heim joints require regular checks, especially if you use them in tough conditions. Most manufacturers suggest that you avoid using grease or oil. Lubricants attract dirt and grit, which can wear out the joint faster. Instead, keep the joints clean and dry.

Stainless heim joints need less care. You do not have to worry much about rust. You should still check them for dirt and damage, but you will spend less time on maintenance.

Expected Service Life

Heim joints do not last forever. You should think of them as wear items, just like brake pads or tires. The lifespan of a heim joint depends on how you use it and where you drive.

If you keep your chromoly heim joints clean and check them often, they can last for many miles. Some users report that their joints last up to 100,000 miles with good care. Others see joints fail after only 250 miles in harsh conditions. The environment makes a big difference. Stainless heim joints can last for 1、2 years or more.

You should plan to replace heim joints before they fail. Regular checks and cleaning help you spot problems early. If you use your vehicle every day, set a schedule to inspect and replace joints as needed. This keeps your ride safe and smooth.

Application Guide: Choosing the Right Heim Joint

Off-Road & Racing

You need strong heim joints for off-road and racing. Chromoly heim joints give you the best support in these tough conditions. PTFE-lined ones keep joints moving smoothly. These lubricants help manage heat and stop dirt from sticking. You get better performance and less wear.

If you race or drive on rocky trails, chromoly heim joints work well. You should check them often and keep them clean. Dirt and mud can wear down coatings, so regular care helps them last longer.

Marine & Outdoor

You face water, salt, and mud in marine and outdoor settings. Stainless heim joints work best here. Stainless steel resists rust and does not need extra coatings. You spend less time on maintenance. These joints keep moving smoothly even after many wet trips.

You can use stainless heim joints for boats, trailers, and outdoor machines. You do not need to worry about rust or frequent repairs. Stainless steel heim joints keep working well in harsh weather. You get smooth movement and less trouble over time.

Street & Daily Use

You use heim joints for street and daily vehicles to improve steering and suspension. You need to pick the right size and mount them correctly. Most failures happen when you choose joints that are too small or mount them at the wrong angle.

Here are common problems you should avoid:

- Undersized heims – Small rod ends break quickly.

- Improper mounting angles – Bad alignment causes binding.

- Skipping lubrication – Dry joints wear out fast.

- No misalignment spacers – Joints need spacers for full movement.

- Mixing hardware grades – Weak bolts can snap under load.

You can use either chromoly or stainless heim joints for daily driving. Chromoly gives you more strength. Stainless offers better rust protection. You should check your joints often and keep them clean. Lubricate them to prevent wear.

Ultimately, the choice between chromoly and stainless steel heim joints comes down to one question: What is your biggest threat? If your vehicle faces extreme mechanical stress, high-speed impacts, or heavy towing, chromoly heim joints is the clear winner. On the other hand, if your biggest enemy is moisture, salt, or time, then Stainless Steel heim joint is the smarter investment. Profab Machine can match the material to your specific environment and performance needs, ensuring a safer, smoother, and more cost-effective ride for the long haul.

FAQ

What is the main difference between chromoly and stainless heim joints?

Chromoly heim joints give you more strength. Stainless heim joints resist rust better. You should choose based on your project’s needs.

Can you use chromoly heim joints in wet or salty environments?

Yes, but they need coatings and regular cleaning. Rust can form if you skip maintenance.

Are stainless heim joints strong enough for racing?

Stainless heim joints work for light racing and daily driving. For heavy racing or off-road use, you need chromoly for extra strength.

How often should you check or replace heim joints?

You should inspect heim joints every few months. Replace them if you see wear, rust, or loose movement. Regular checks keep your vehicle safe.

Send Inquiry Now

Related Resource

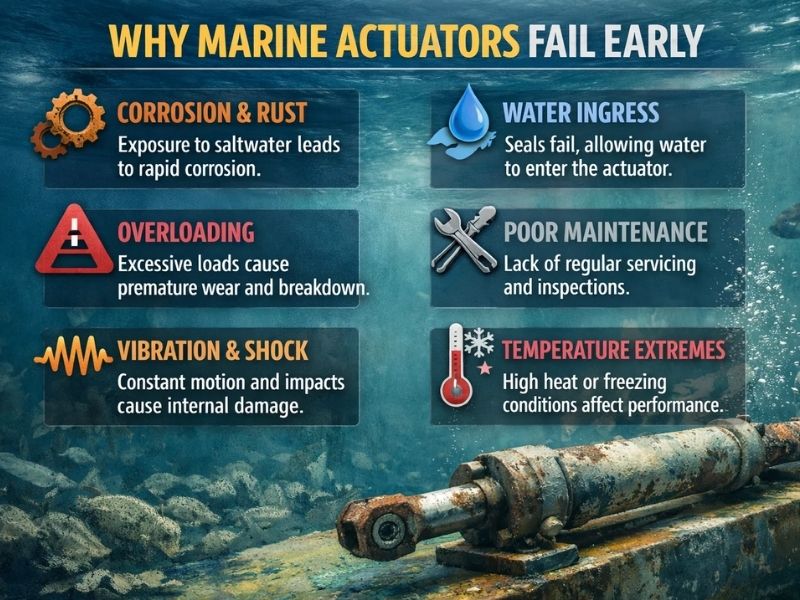

Why Marine Actuators Fail Early

Why Axle Spacers Matter To Wheelchairs: How to Use, Replace, and Maintain Them