- By Profab /

- September 1, 2025

You might wonder, Will Stainless Steel Rust? Stainless steel resists rust better than regular steel, but it is not completely immune. The secret lies in a thin chromium oxide layer on the surface. This layer forms when chromium meets oxygen. It creates a self-healing shield that protects the metal underneath from rust. If this shield gets damaged, it can repair itself as long as oxygen is present.

Key Takeaways

- Pick the right stainless steel grade for your needs. Grade 316 works best near the ocean or with chemicals. Grade 304 is good for most other uses.

- Clean and dry stainless steel often to stop rust. Use gentle soap and do not use strong cleaners.

- Do not let stainless steel touch saltwater or strong chemicals. These things can hurt the protective layer and make it rust.

- If you see rust, you can use baking soda or lemon juice to clean it. Always scrub in the same direction as the grain.

Table of Contents

Will Stainless Steel Rust?

Why Stainless Steel Resists Rust

You might ask, “Will Stainless Steel Rust?” The answer depends on how you use it. Stainless steel does not rust as easily as regular steel. This is because of what is inside it. Manufacturers add chromium to the steel. The chromium amount is usually between 17% and 28%. Chromium mixes with oxygen in the air. It makes a thin layer called chromium oxide. This layer is invisible. It works like a shield. It stops water and air from touching the iron inside. If the layer gets scratched, it can fix itself if there is oxygen.

Other things like nickel, molybdenum, and nitrogen help too. Nickel makes the steel stronger and helps stop rust. Austenitic stainless steels have more nickel. These are used in food and medical tools. Molybdenum and nitrogen give extra protection. They help in tough places.

Did you know?

Here is a quick summary of why stainless steel resists rust:

- Chromium makes a protective oxide layer.

- Nickel makes the steel stronger and stops rust.

- Molybdenum and nitrogen give extra help.

- The shield can fix itself if it gets damaged.

Scientists found that stainless steel fights rust better than other metals. The mix of chromium, nickel, and other things makes a film. This film keeps rust away, even in hard conditions.

What Causes Rust on Stainless Steel

Sometimes, rust shows up on stainless steel. This happens because of the environment and how you use it. The chromium oxide shield can break down. When this happens, iron inside reacts with oxygen and water. This makes rust.

Common reasons for rust on stainless steel are:

- Using strong chemicals like acids or bleach.

- Touching saltwater or salty air.

- High heat can hurt the shield.

- Scratches or dents show the metal inside.

- Leaving it near some materials like carbon steel for a long time.

The place matters a lot. Tough places like factories or near the sea can make rust faster. If stainless steel touches other metals or chemicals for a long time, rust can form.

Here is a table that explains the chemical reactions behind rust formation:

Evidence Description | Key Points |

Stainless steel is mostly iron with chromium and nickel. | Chromium helps stop rust by making a protective layer. |

Chromium mixes with oxygen to make a shield. | This shield keeps steel safe from oxygen and water, which cause rust. |

Sometimes, the shield can get weak. | If this happens, iron can reach the surface and rust starts. |

Chloride ions are in saltwater and some cleaners. They can break through the shield. This causes pitting corrosion, which makes tiny holes. More chloride ions mean rust happens faster.

Evidence | Description |

Chloride ions’ impact | Chloride ions are small, stick well, and break the shield, making rust worse. |

Corrosion types | More Cl− makes carbon steel rust all over and stainless steel get tiny pits. |

Do not use strong chemicals or leave stainless steel in salty places for long. Scratches and dents also make rust easier.

Will Stainless Steel Rust in Water

You may wonder, “Will stainless steel rust in water?” The answer depends on the water and the steel type. Freshwater does not cause much rust. Saltwater is different. Saltwater has chloride ions. These attack the shield and cause pitting corrosion. Even rain and sea spray can bring salt and cause rust.

Here are some facts about stainless steel and water:

- Saltwater makes rust happen faster because of chloride ions.

- Freshwater can cause rust, but it is not as bad as saltwater.

- Rain and sea spray can also cause rust, especially near the ocean.

If you use stainless steel outside or near the sea, pick grades with more chromium and nickel. These grades fight rust better in wet and salty places. Clean and dry stainless steel often to keep the shield strong.

Tips

When Does Stainless Steel Tarnish or Rust

Stainless steel can tarnish or rust if its shield gets damaged. You may wonder, “Does stainless steel tarnish?” The answer is yes, especially in tough places. Here are some main reasons why problems happen:

- Saltwater or pool water can make dull spots or tarnish.

- High humidity can cause rust if you do not clean it often.

- Water that stays on the surface can mix with dirt or chemicals. This can make stains or small holes.

Chemical and Saline Exposure

Stainless steel is most at risk when it touches chemicals or salty things. Chloride anions, found in saltwater and some cleaners, can break the shield. These anions are in many places, like clay soil and salt rocks. Some places have a lot of chloride, up to 100,000 mg/L. Using stainless steel in pools, near the sea, or with chlorine cleaners makes rust more likely. Hot temperatures and low pH make it worse. Always rinse and dry stainless steel after it touches these things.

Heat and Welding Effects

Heat can hurt the shield on stainless steel. When you weld or heat it, the surface can lose its chromium oxide shield. This makes it easier for rust to start. You might see rainbow colors or dark spots after welding. These show tarnish. If you use stainless steel in kitchens or factories, look for these signs. Clean and polish it to make it shiny again.

Surface Contamination

Touching other metals or getting dust on stainless steel can cause rust. Here is a table that lists common things that cause problems and what they do:

Contaminant | Source of Contamination | Effect on Stainless Steel |

Free Iron | Tools used on mild steel, grinding dust, atmospheric iron deposits | Causes surface rust and can lead to pitting |

Carbon | Welding to carbon steel, using markers on both materials | Leads to rust formation on the surface |

Chloride | Hydrochloric acid, salt from sweat | Can cause localized corrosion |

Mild Steel | Tools or dust from mild steel fabrication | Results in rust spots on stainless steel surfaces |

To stop rust, keep stainless steel clean and use different tools for each metal.

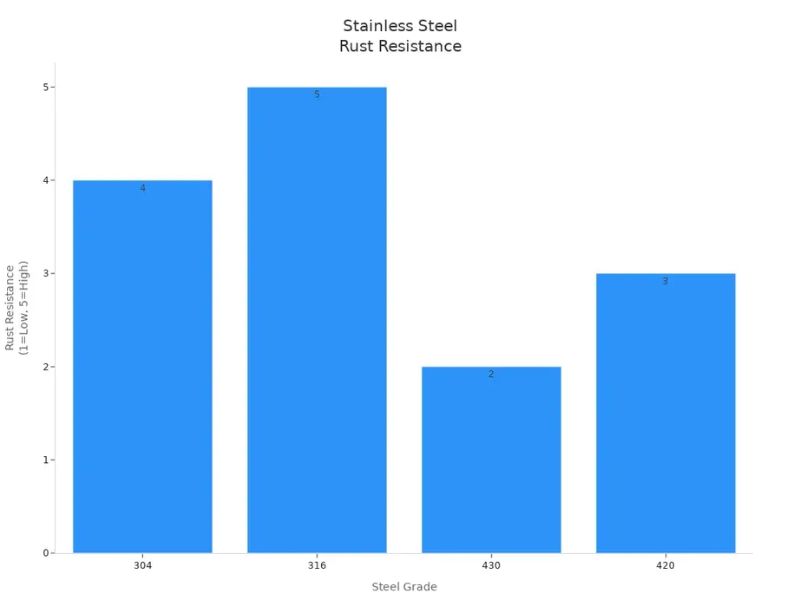

Stainless Steel Grades and Rust Resistance

When you choose stainless steel, you need to know how different grades resist rust. Some grades work better in tough places, while others suit everyday use. You might ask, “Will Stainless Steel Rust?” The answer depends on the grade and where you use it.

304 vs 316 Stainless Steel

You see 304 and 316 stainless steel everywhere. Both grades have high chromium and nickel, but 316 has molybdenum. This extra element helps 316 fight rust from salt and chemicals. If you wonder, “Will 304 stainless steel rust?”—it can, especially near the ocean or in salty air. “Will 316 stainless steel rust?”—it resists rust much better in those places.

Here are the main differences:

- 316 stainless steel contains molybdenum, which boosts corrosion resistance.

- 304 stainless steel does not have molybdenum, so it is less resistant to salt and chemicals.

- 316 is best for marine or chemical environments.

- 304 works well for food, medical, and indoor uses.

Grade | Composition | Corrosion Resistance | Common Uses |

304 | 18-20% chromium, 8-10% nickel | Excellent, widely used | Food processing, medical devices, construction |

316 | 10-14% nickel, 2-3% molybdenum | Superior, ideal for harsh environments | Marine applications, surgical instruments |

430 | 17-18% chromium, no nickel | Limited, not for corrosive environments | Decorative purposes |

420 | 12% chromium | High, used for surgical instruments | Blade grade steel, surgical tools |

Tips

17-4 and 18-8 Stainless Steel

You might see grades like 17-4 and 18-8. These numbers show the mix of chromium and nickel. “Will 17-4 stainless steel rust?”—it resists rust well but can pit in strong saltwater. “Will 18-8 stainless steel rust?”—it performs like 304 and 316, but can still pit in high-chloride areas.

Stainless Steel Grade | Corrosion Resistance in Saltwater | Notes |

17-4PH | Good overall, like 304 | Can pit in severe chloride exposure |

18-8 (304/316) | Excellent, but can pit | Works well in marine air, but not in strong saltwater |

You should check the environment before picking these grades. For most outdoor uses, 18-8 works well. For heavy salt or chemicals, you need a higher grade.

Choosing the Right Grade

You want your stainless steel to last. Think about where you will use it. Here are some tips:

- Grade 304 suits general outdoor use, but may corrode near the sea.

- Grade 316 works best for marine or chemical places.

- Grade 316L is great for welded outdoor structures.

- Coastal buildings need 316 for salt protection.

- Inland areas can use 304 for many years.

Stainless steel needs little cleaning. Soap and water keep it shiny. You do not need special maintenance. If you ask, “Will Stainless Steel Rust?”—choose the right grade and clean it often to keep rust away.

Grade | Will Rust in Saltwater? | Best Use |

304 | Yes, in coastal areas | General outdoor, indoor |

316 | Rarely | Marine, chemical |

17-4PH | Sometimes | Industrial, marine |

18-8 | Sometimes | Food, medical, marine |

Preventing Rust and Tarnish

Cleaning and Maintenance

You can keep stainless steel shiny by cleaning it often. Dirt and water help rust grow, so wipe surfaces regularly. Use a soft cloth or sponge to clean. Do not use steel wool because it scratches and leaves iron. For tough stains, use special cleaners made for stainless steel. Some acids can remove rust without hurting the metal

Cleaning Method | Description |

Phosphoric Acid | Breaks down rust but does not harm stainless steel; rinse with clean water after using. |

Acetic Acid | Works slowly and is good for big rusty spots; rinse well after cleaning. |

Protective Coatings | Strong coatings like Silcolloy® and Dursan® help stop rust. |

Overall, stainless steel is not absolutely rust-proof, but the risk of corrosion and discoloration can be greatly reduced with the right selection of materials and proper surface preparation.

Profab Machine can provide an integrated solution from material selection and precision machining to electrolytic polishing and passivation. Contact Profab Machine to optimize the balance between corrosion resistance and cost.

FAQ

Can stainless steel rust if scratched?

Yes, scratches can damage the protective layer. You expose the iron underneath. Rust may form if you do not clean and dry the area quickly.

How often should you clean stainless steel to prevent rust?

You should clean stainless steel once a week. Wipe with a soft cloth and mild soap. Dry the surface after cleaning to keep it shiny.

Does saltwater cause stainless steel to tarnish faster?

Saltwater speeds up tarnish and rust. Chloride ions break the protective layer. You should rinse and dry stainless steel after contact with saltwater.

Send Inquiry Now

Related Resource

What are Stainless Steel Ball Transfer Units Used For?

How to Select Grease for Rose Joints